1MAC309294-MB F Section 4

Protection functions

RER620 141

Technical Manual

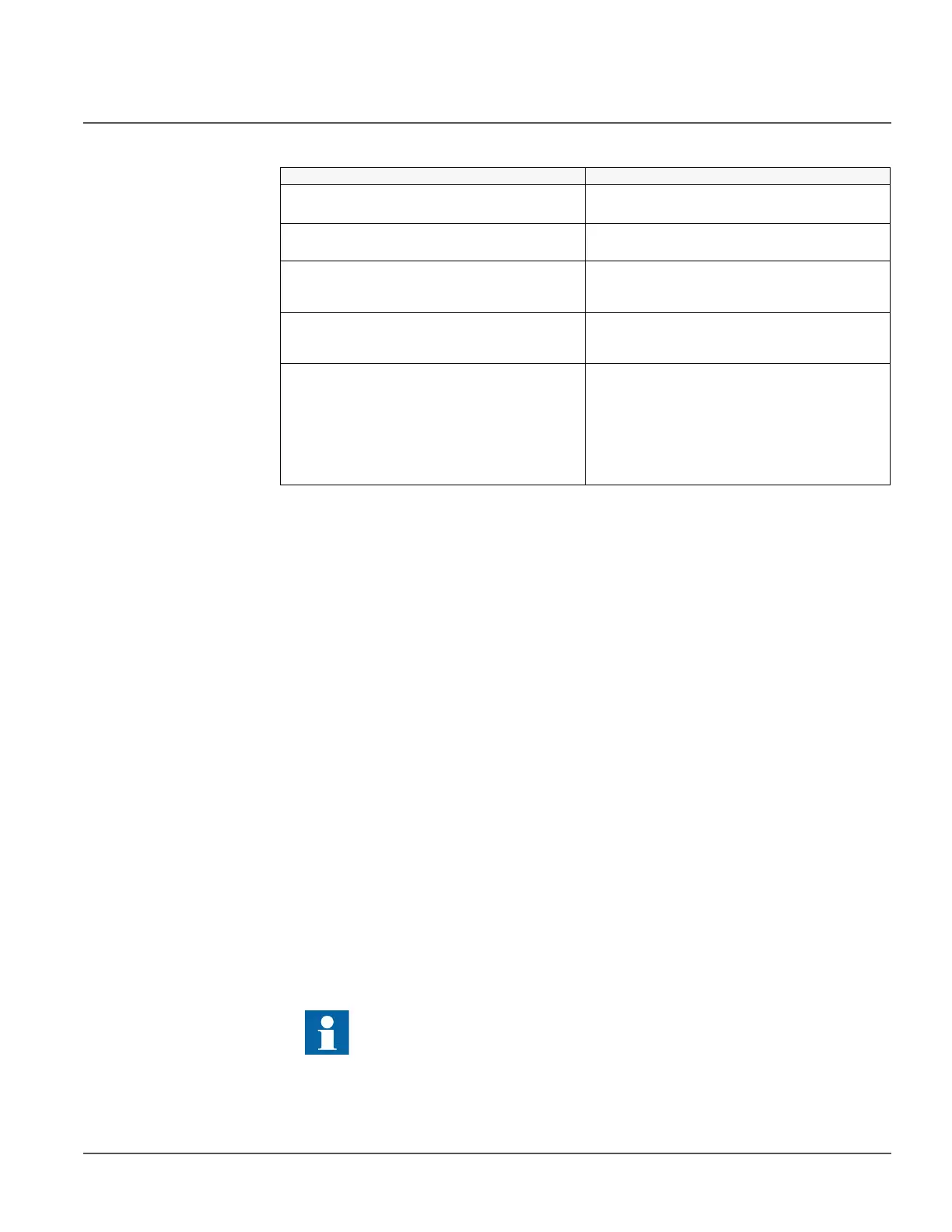

Table 163: Monitored data values

Monitored data values are accessible on the LHMI or through tools via communications.

Timer

Once activated, the timer activates the PICKUP output. Depending on the value of the

Operating curve type setting, the time characteristics are according to DT or IDMT. When

the operation timer has reached the value of Trip delay time in the DT mode or the

maximum value defined by the inverse time curve and the Time adder time has expired,

the TRIP output is activated.

When the user programmable IDMT curve is selected, the operate time characteristics are

defined by the parameters Curve parameter A, Curve parameter B, Curve parameter C,

Curve parameter D and Curve parameter E.

If a drop-off situation happens, that is, a fault suddenly disappears before the trip delay is

exceeded, the timer reset state is activated. The functionality of the timer in the reset state

depends on the combination of the Operating curve type, Type of reset curve and Reset

delay time settings. When the DT characteristic is selected, the reset timer runs until the

set Reset delay time value is exceeded. When the IDMT curves are selected, the Type of

reset curve setting can be set to “Immediate”, “Def time reset” or “Inverse reset”. The

reset curve type “Immediate” causes an immediate reset. With the reset curve type “Def

time reset”, the reset time depends on the Reset delay time setting. With the reset curve

type “Inverse reset”, the reset time depends on the current during the drop-off situation. If

the drop-off situation continues, the reset timer is reset and the PICKUP output is

deactivated.

The setting Time multiplier is used for scaling the IDMT trip and reset times.

Monitored data values Description

FAULT_DIR The detected direction of fault during fault situations,

that is, when START output is active.

DIRECTION The momentary operating direction indication

output.

ANGLE Also called operating angle, shows the angle

difference between the VG (polarizing quantity) and

Io (operating quantity).

ANGLE_RCA The angle difference between the operating angle

and

Characteristic angle

, that is, ANGLE_RCA =

ANGLE –

Characteristic angle

.

I_OPER The current that is used for fault detection. If the

Operation mode

setting is

“

Phase angle

”

,

“

Phase

angle 80

”

or “Phase angle 88

”

, I_OPER is the

measured or calculated residual current. If the

Operation mode

setting is

“

IoSin

”

, I_OPER is

calculated as follows I_OPER = Io x sin(ANGLE). If

the

Operation mode

setting is “IoCos”, I_OPER is

calculated as follows I_OPER = Io x cos(ANGLE).

The “Inverse reset” selection is only supported with ANSI or user

programmable curves. If another operating curve type is selected, an

immediate reset occurs during the drop-off situation.

Loading...

Loading...