K65C/K75C/K95C

7-5

K65C/K75C/K95C

7-5

NOTE

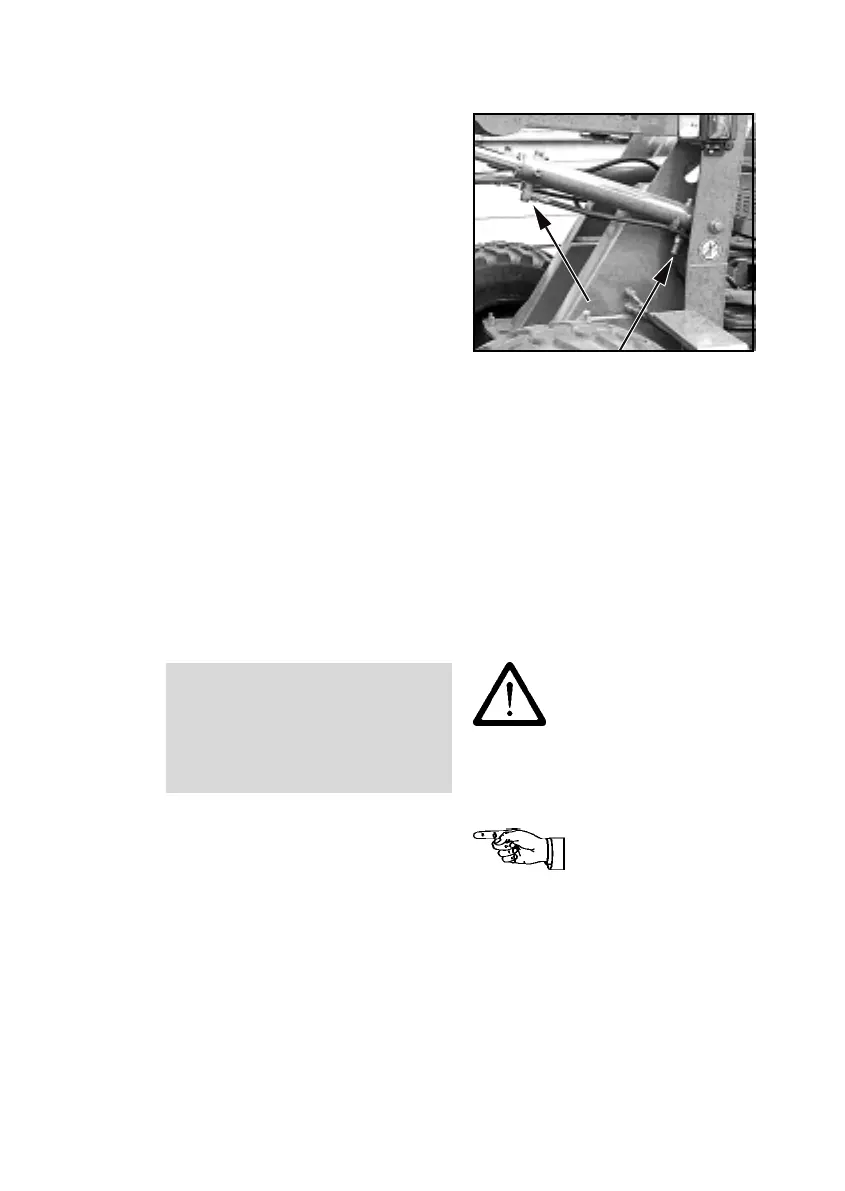

- If the failure has occurred some

time ago, the hydraulic hoses

(7-7/arrows) must be disconnec-

ted from the lifting cylinders be-

fore the lifting gear is attached.

Collect the hydraulic oil that es-

capes in a drain pan of sufficient

size.

- After towing has been com-

pleted, fill the lifting cylinders

with hydraulic oil and deaerate

them by raising and lowering the

bucket arm several times.

7.1.1.2Towing the articu-

lated loader if the drive has

failed

(1) Press the toggle switch for the

hazard flasher (4-13/10).

(2) Set the drive switch (4-12/6) to

position "0".

(3) Apply the parking brake

(4-12/3).

CAUTION

If the rescue location is on a slope,

wheel chocks must be placed on

the sloping side of both front axle

wheels in addition to applying the

parking brake.

NOTE

The preparations described in steps

(4) and (5) are only to be carried out

if the rescue location is not on a

public road:

(4) Cover the bucket cutting edge

and teeth with the bucket protector

(5-2/arrow).

Figure 7-7

NOTE

- If the failure has occurred some

time ago, the hydraulic hoses

(7-7/arrows) must be disconnec-

ted from the lifting cylinders be-

fore the lifting gear is attached.

Collect the hydraulic oil that es-

capes in a drain pan of sufficient

size.

- After towing has been com-

pleted, fill the lifting cylinders

with hydraulic oil and deaerate

them by raising and lowering the

bucket arm several times.

7.1.1.2Towing the articu-

lated loader if the drive has

failed

(1) Press the toggle switch for the

hazard flasher (4-13/10).

(2) Set the drive switch (4-12/6) to

position "0".

(3) Apply the parking brake

(4-12/3).

CAUTION

If the rescue location is on a slope,

wheel chocks must be placed on

the sloping side of both front axle

wheels in addition to applying the

parking brake.

NOTE

The preparations described in steps

(4) and (5) are only to be carried out

if the rescue location is not on a

public road:

(4) Cover the bucket cutting edge

and teeth with the bucket protector

(5-2/arrow).

Figure 7-7

Loading...

Loading...