Testing Procedures

TT

TT

T

o ao a

o ao a

o a

vv

vv

v

oid the risk of electric shocoid the risk of electric shoc

oid the risk of electric shocoid the risk of electric shoc

oid the risk of electric shoc

k,k,

k,k,

k,

per per

per per

per

sonal injursonal injur

sonal injursonal injur

sonal injur

y ory or

y ory or

y or

death, disconnect power before servicing, unless testingdeath, disconnect power before servicing, unless testing

death, disconnect power before servicing, unless testingdeath, disconnect power before servicing, unless testing

death, disconnect power before servicing, unless testing

requires it.requires it.

requires it.requires it.

requires it.

WARNING

RS2310002 Rev. 1 38

Gas Thermostat

This system uses a thermostat which internally selects

the Bake, Broil, and Clean circuits eliminating the

separate selector switch.

Verify voltage being supplied to the gas thermostat by

measuring voltage at terminal 2 of the gas thermostat,

meter should indicate 120 VAC.

Verify gas thermostat is working correctly by measuring

voltage at BA in bake mode, BR in broil mode, and C in

clean mode. All terminal points should indicate 120 VAC.

Dial Contacts

1-2

Main COM-NO COM-NC C-BR C-BA 7-9

Low Stop N.S. O X O O O

Bake C

cles N.S. N.S. O X O

Broil Cycles N.S N.S. X O O

Clean Cycles X Below

700° F

X Above

700° F

OOX

NOTE: When switching oven thermostat from broil to

bake always turn fully to OFF first. Otherwise

the broil burner remains on by the thermostat.

1

2

COM

N.C.

N.O.

BR

BA

9

12

7

NO

NC

9BABR

COM

C

Oven Temperature Sensor

The oven temperature sensor can be checked by using

the "Quick Test Mode" covered in this section of manual

or detail testing can be accomplished as follows.

The oven temperature sensor is mounted in the oven

cavity and electrically connected to the ERC. Following

is approximate resistance.

75°F — 1082 ohms

350°F — 1656 ohms

550°F — 2056 ohms

880°F — 2686 ohms

Sensor resistance can be checked by removing the

sensor interconnect harness plug from the ERC and

inserting ohmmeter leads into the harness connector

plug. A resistance reading of approximately 1100 ohms

should be indicated at ambient room temperature

(75°F.). If a higher resistance is indicated then remove

sensor from oven, disconnect sensor from harness at

plug, and recheck sensor resistance to assure that the

problem is in the sensor and not in the interconnect

harness or due to a bad connection.

NOTE: Sensor resistance will increase if held in your

hand.

Cooling Fan Motor

Fan may come on at any time to cool components

down.

1. Turn off power to oven.

2. Disconnect wires from motor terminal connectors.

3. Attach ohmmeter leads to terminal tabs on motor.

4. A resistance reading of 15-30 ohms should be

indicated but may vary with each motor tested. This

test is to check the motor winding for an open or

shorted winding. If zero or infinite ohms is indicated,

the motor winding has failed and the motor must be

replaced.

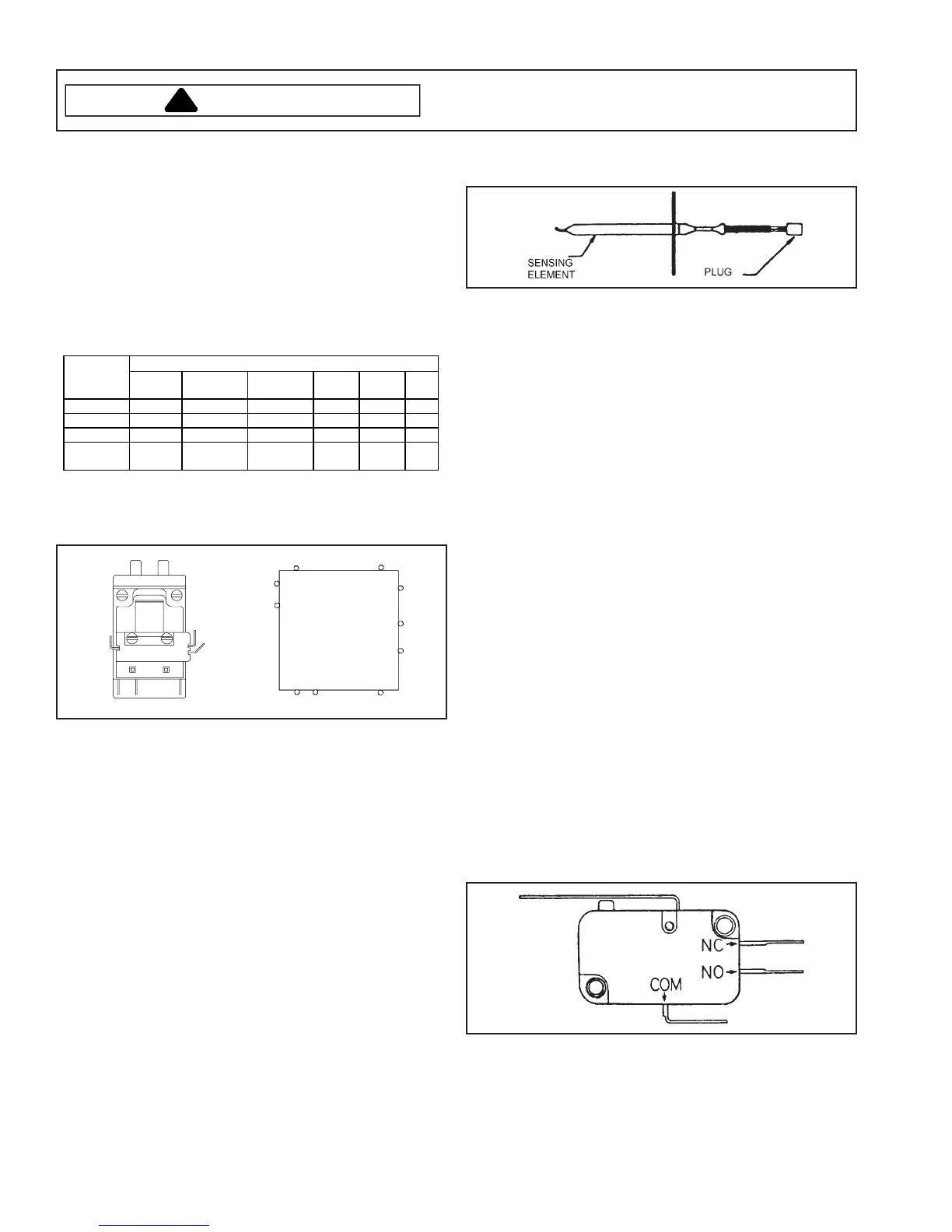

Clean Circuit Manual Latch Switch

The latch switch is a single pole, single throw switch.

When the door latch is moved to the far right or locked

position, the switch contacts COM-NO provide a

connection path from gas thermostat to the clock timer,

terminal AT3.

The switch contacts can be checked as follows:

1. Turn off power to range.

2. Disconnect the switch wire leads and check the

COM-NO and COM-NC contacts for continuity.

3. When the door latch is in the left or unlocked

position, the COM-NO contacts should be open and

the COM-NC contacts should be closed.

4. Move the door latch to the far right or locked position.

The COM-NO contacts should be closed and the

COM-NC contacts should be open.

Loading...

Loading...