29 RS2310002 Rev. 1

Installation Instructions for Freestanding Ranges

Natural Gas

1. Remove storage drawer.

• “Removing Storage Drawer”

section.

2. Locate and remove screws attaching Z-shaped cover

plate.

• Cover plate located in center, rear of storage drawer

cavity.

• Removing cover plate exposes oven burner orifice

and air shutter.

3. Turn orifice hood counterclockwise 2 full turns.

• Support tubing/fitting with wrench while turning

hood.

4. Replace cover plate and storage drawer.

Converting Broiler Burner for Use with

Natural Gas

1. Locate orifice spud attached adjacent to pressure

regulator and remove for later use.

• Orifice spud used for natural gas is silver and is

stamped “52”.

2. Open oven door and locate broiler burner on oven

ceiling.

• Remove oven door to make conversion easier. See

“Removing Oven Door”

section.

3. Remove 2 screws securing front of burner to oven

ceiling and remove broiler.

• Be careful not to damage ignitor as you remove

broiler.

4. Unscrew LP/propane burner spud stamped “58” with

5

/16 inch socket wrench and replace with natural gas

burner spud stamped “52”.

5. Reinstall broiler and, if necessary, oven door.

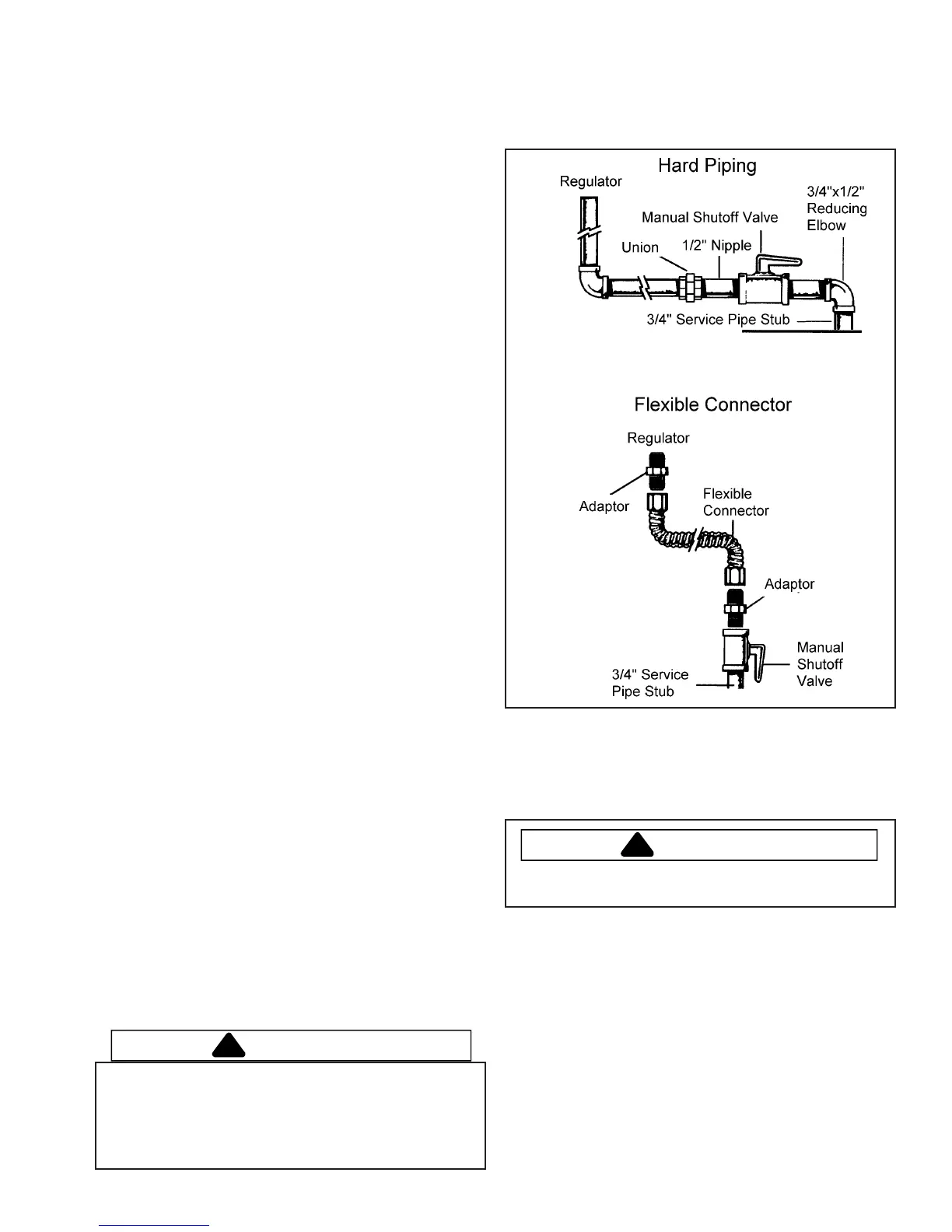

Gas Connection

Connect gas supply to regulator using hard pipe or a

flexible connector. Pressure regulator supplied with this

appliance has a ½ inch NPT female connection. If gas

union is used, remove storage drawer, slide range into

place, and connect union. See figure below.

• A manual shutoff, not supplied with range, must be

installed in an accessible location outside of range.

• Use joint compound that is resistant to action of

propane gas on all male pipe threads.

• Use supplied pressure regulator only.

• Do not overtighten gas fitting when attaching to

pressure regulator. Overtightening may crack regulator.

• Support pressure regulator with wrench when installing

gas fitting.

WARNING

To avoid property damage or personal injury, only use a

new flexible connector that is AGA/CGA design

certified.

• Do not use an old connector.

• Do not reuse a connector after moving

appliance.

Testing for Gas Leaks

After final gas connection is made, turn on manual gas

valve and test all connections in gas supply piping and

range for gas leaks.

WARNING

To avoid property damage or serious personal injury,

never use a lighted match to test for gas leaks.

1. Place soap suds on connection.

• Bubbles appear if leak is present.

2. If bubbles appear, shut off gas supply valve.

3. Tighten joint if leak is at factory fitting.

• If leak is not at factory fitting, unscrew, apply more

joint compound, and tighten to correct leak.

4. Retest connection for leak after tightening.

• Retest any connections that were disturbed.

Loading...

Loading...