58

001-15698-EN rev.12

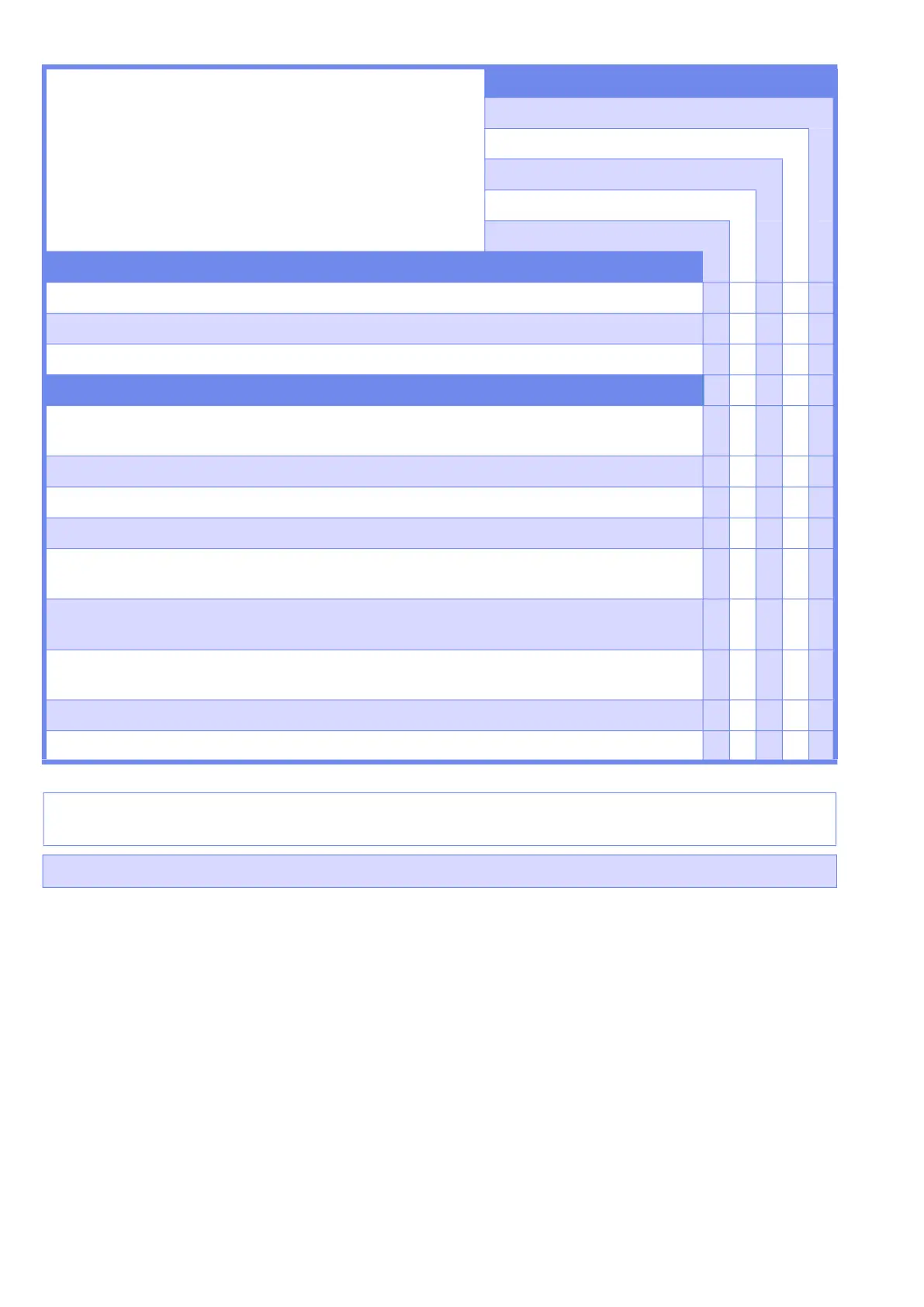

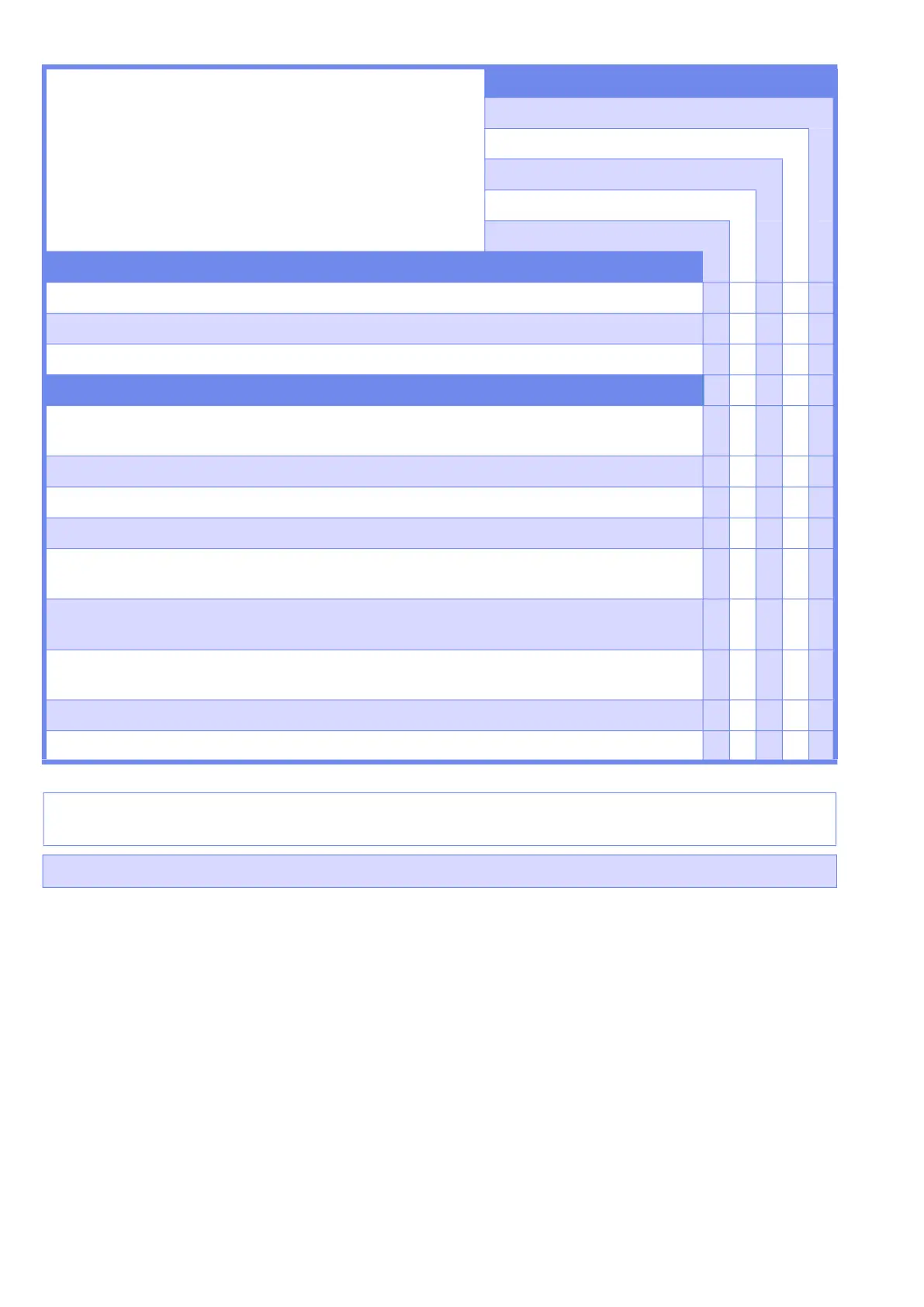

Inspections for Rails

FREQUENCY

Every two years or 5000 cycles

Every year or 2500 cycles

Every four months or 1000 cycles

Before every use

Initially

USER INSPECTION

Clean the inside of the rail to remove accumulated dust on the rolling surface.

√ √

Clean the charging station contacts with a damp cloth. √

Make sure that end stoppers, charging station and rail caps are in place. √ √

INSPECTION BY AN AUTHORIZED SERVICE TECHNICIAN

Torque end stoppers to 20 Nm (15 lbf ft) except those that pass edgeways through

the track (bolt end stoppers).

√ √

Make sure that the bracket locking device is not visible. √ √

Make sure rail joints are closed and that the spring pins are centred. √ √

Make sure the rail is levelled when it is not loaded. √ √

Make sure the adjusted load setting of the lift is equal or lower than the safe working

load of the installation.

√ √

Check that the accessories (X-Y system, Gate, Exchanger, Turntable, Receiving

module and PPP) are complete and correctly maintained.

√ √

Make sure that the attachments (ceiling brackets, wall post, wall brackets) have not

been displaced, damaged or removed.

√ √

Inspect track end stoppers. Inspect and tighten hardware (if necessary). √

Load test with the SWL (safe working load). √

NOTE: If the product does not work as intended, immediately contact your local Arjo distributor for

support.

WARNING: Before each use, make sure all end stoppers are in place to prevent a fall risk.

Loading...

Loading...