Rubber Track Loader

11. Undercarriage Disassembly and Assembly

11-3

6. With wheels removed, inspect the bearings and

axle for wear or damage.

Sprocket Roller Removal and

Installation

The tools required for sprocket roller removal and

installation are listed in Table 0-2. Use

manufacturer-recommended tools whenever

possible.

Table 0-2

Required Tools

Socket Wrench

Combination Wrench

Note: The rollers should be inspected every 25 hours for

rotation and wear-through. The rollers on the drive

sprocket are easily replaceable. The track DOES NOT

need to be removed to replace these rollers.

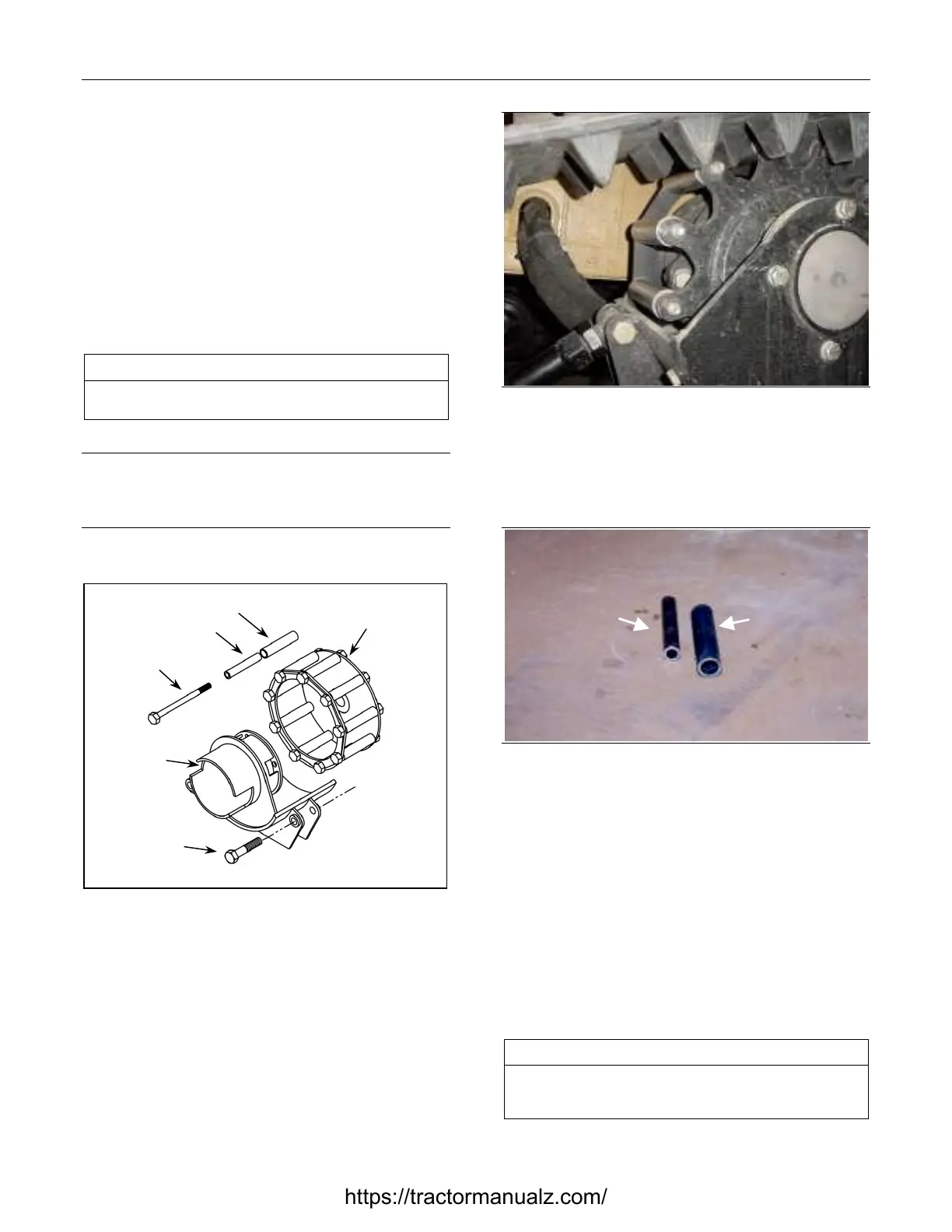

Figure 0-7 12-057

1. Rotate the drive sprocket to allow access to the

sprocket roller bolt. Remove the bolt.

2. Remove the roller and steel pin from the drive

sprocket.

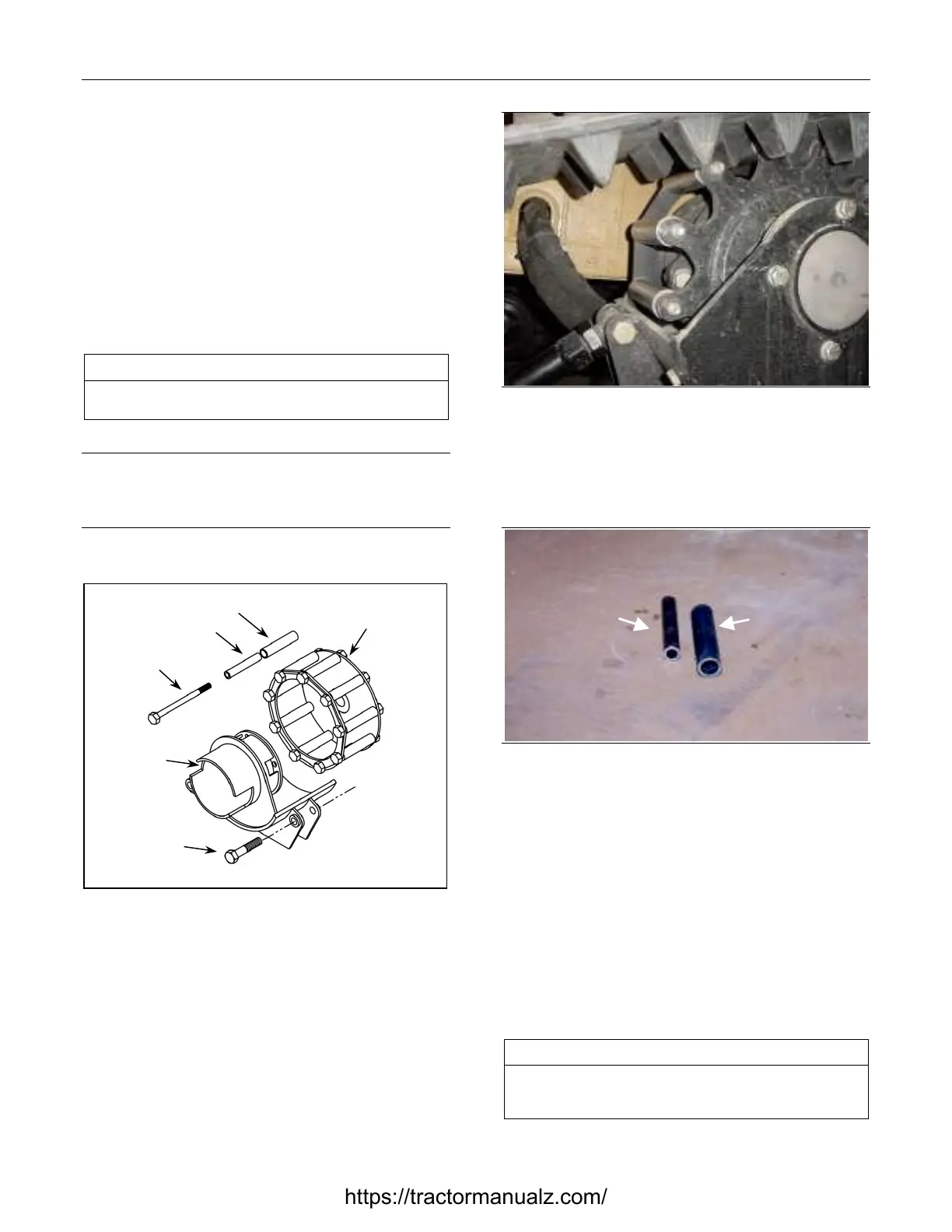

Figure 0-8 12-019

3. Inspect the rollers for wear and replace as

necessary. The inner steel pin will normally not

need replacing unless the roller has worn

completely away and the steel pin is worn.

Track Removal and

Installation

The tools required for track removal and installation

are listed in Table 0-3. Use manufacturer-

recommended tools whenever possible.

Table 0-3

Required Tools

Socket Wrench Floor Jack

Combination Wrench Track Tool

Thread / Seal protector

Steel

Roller

Steel Pin

Roller

Steel Pin

Drive Sprocket

Sprocket

Roller Bolt

Track

Tensioner

Bolt

Motor

Mount

Sprocket

https://tractormanualz.com/

Loading...

Loading...