Rubber Track Loader

13. Maintenance

13-4

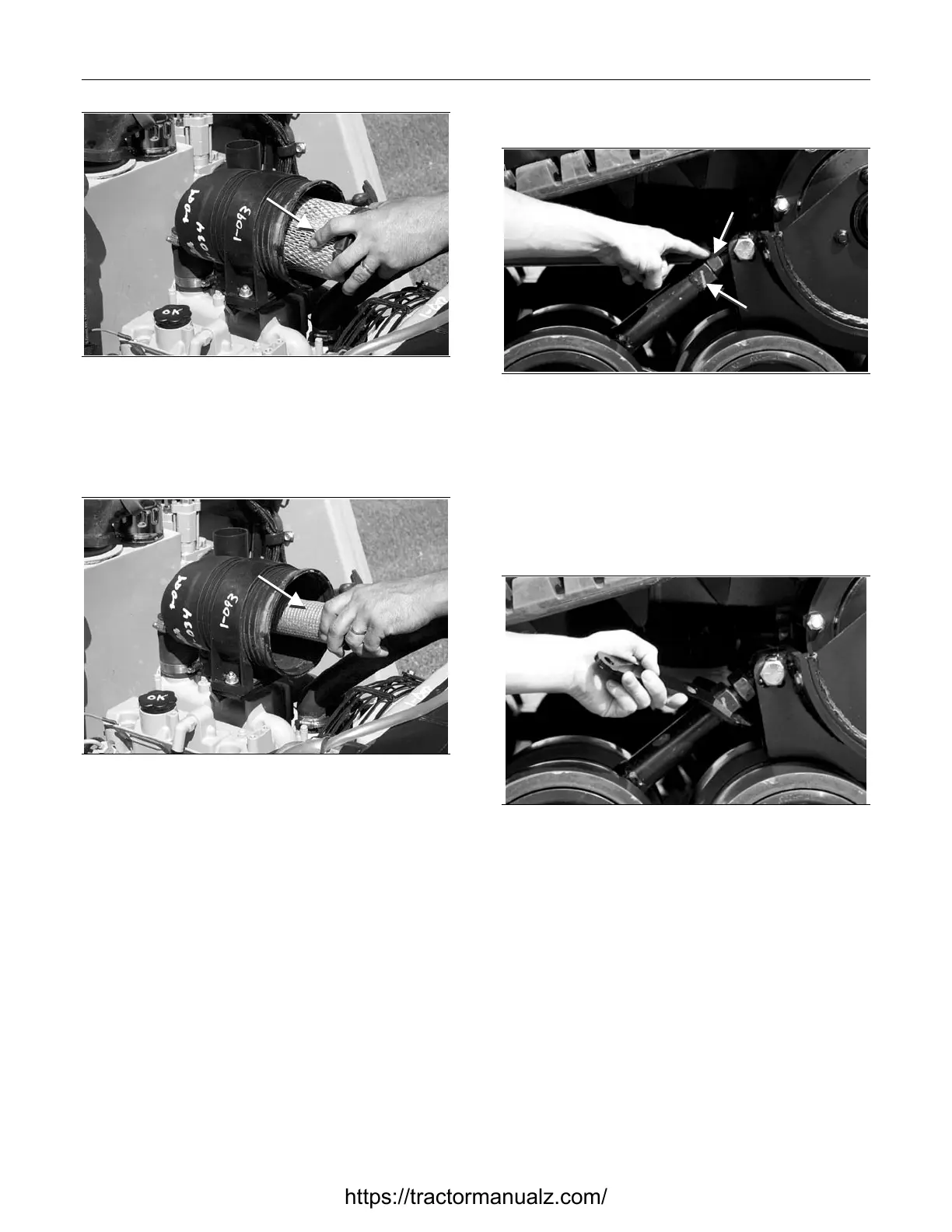

Figure 16-6 16-010

2. Remove the primary element. The primary ele-

ment can be cleaned and reused up to five

times, but it should be changed at least once a

year.

Figure 16-7 16-011

3. Remove the safety element. The safety element

is not serviceable or washable. It should be re-

placed with every three cleanings of the primary

element.

Track Tension

Proper track tension is very important for optimum

performance and long track life. Tracks that are run

too loose can cause misfeeding and ratcheting pos-

sibly causing damage to the track. During the first 50

hours of operation, the tracks will “break in” and will

most likely require adjustment.

Track Tension Adjustment Procedures

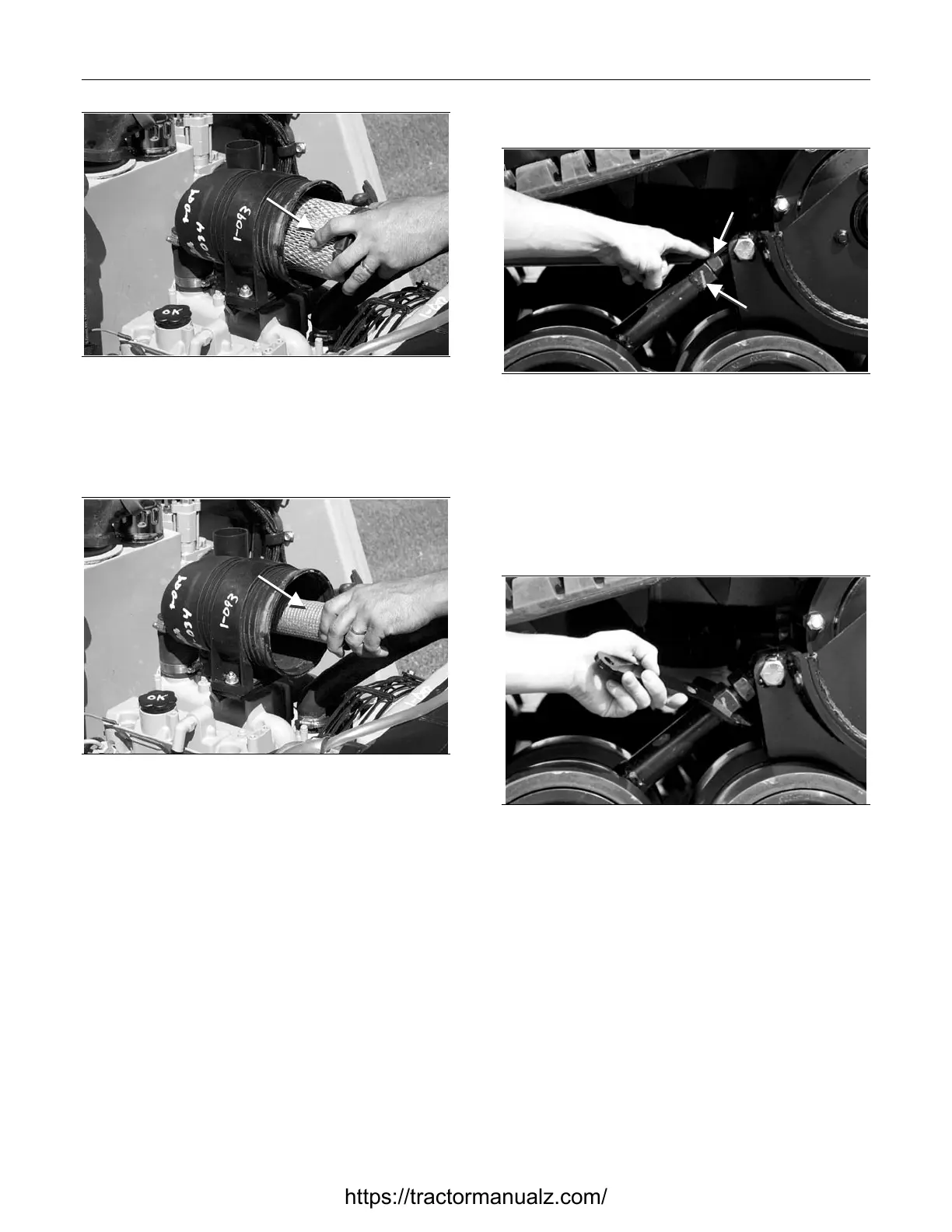

Figure 16-8 16-005

1. Locate the jam nut on the track tensioner and

clean the threads thoroughly before proceeding.

2. Loosen the jam nut. You can use the wrench

supplied with the machine, but a standard

wrench is preferred for shop use.

Figure 16-9 16-007

3. After loosening the jam nut, turn the track ten-

sioner until the track tension is within specifica-

tions.

4. Once proper tension is achieved, retighten the

jam nut

Checking for Proper Track Adjustment

1. Drive the machine forward five feet.

Primary

Element

Safety

Element

Jam

Nut

Track

Tensioner

https://tractormanualz.com/

Loading...

Loading...