Rubber Track Loader

11. Undercarriage Disassembly and Assembly

11-6

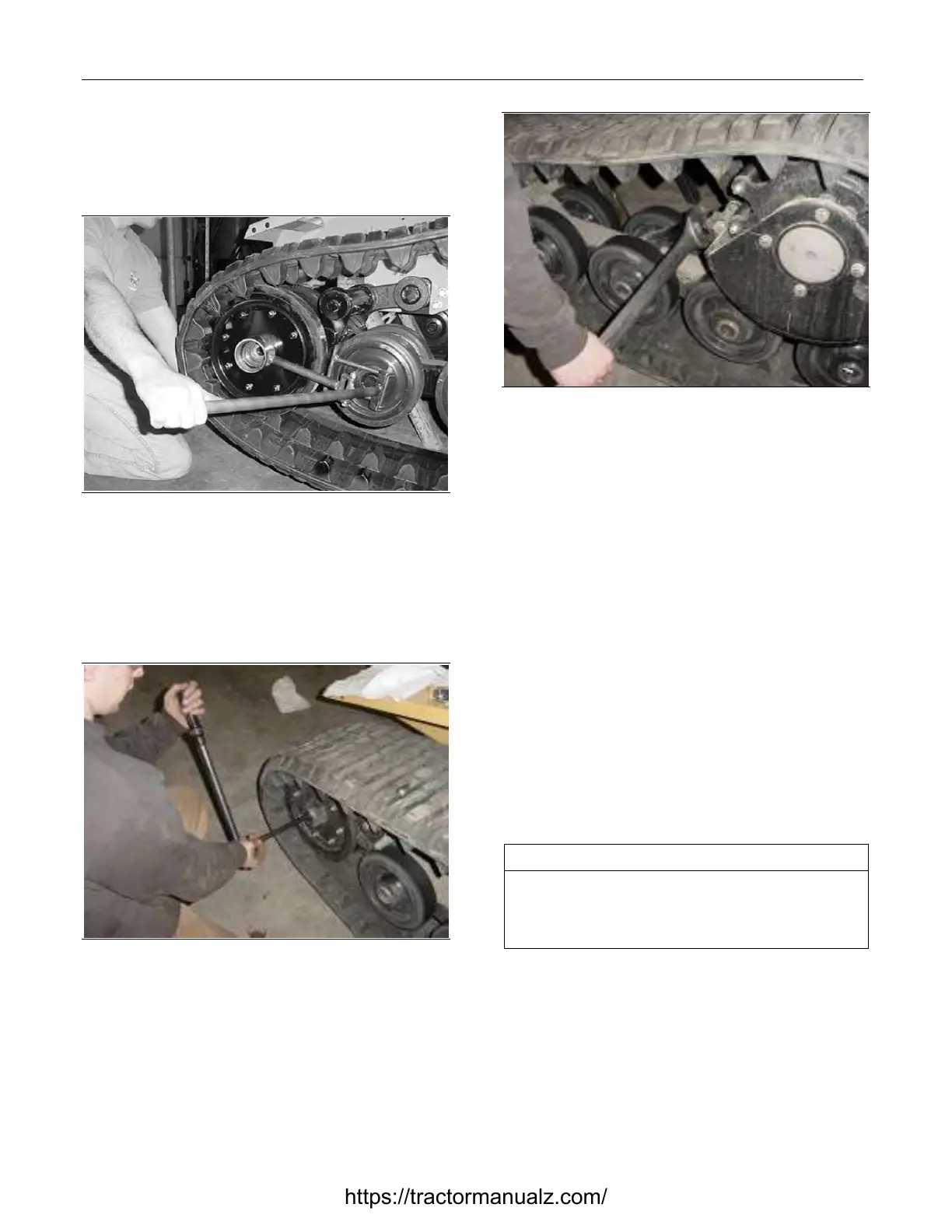

4. Install the track tool as shown in Figure 0-15.

5. Install the track tool’s collar over the 14” wheel

hub, make sure the collars hinge bolt is closest

to the wheel hub. See figure 12-16.

Figure 0-16 12-053

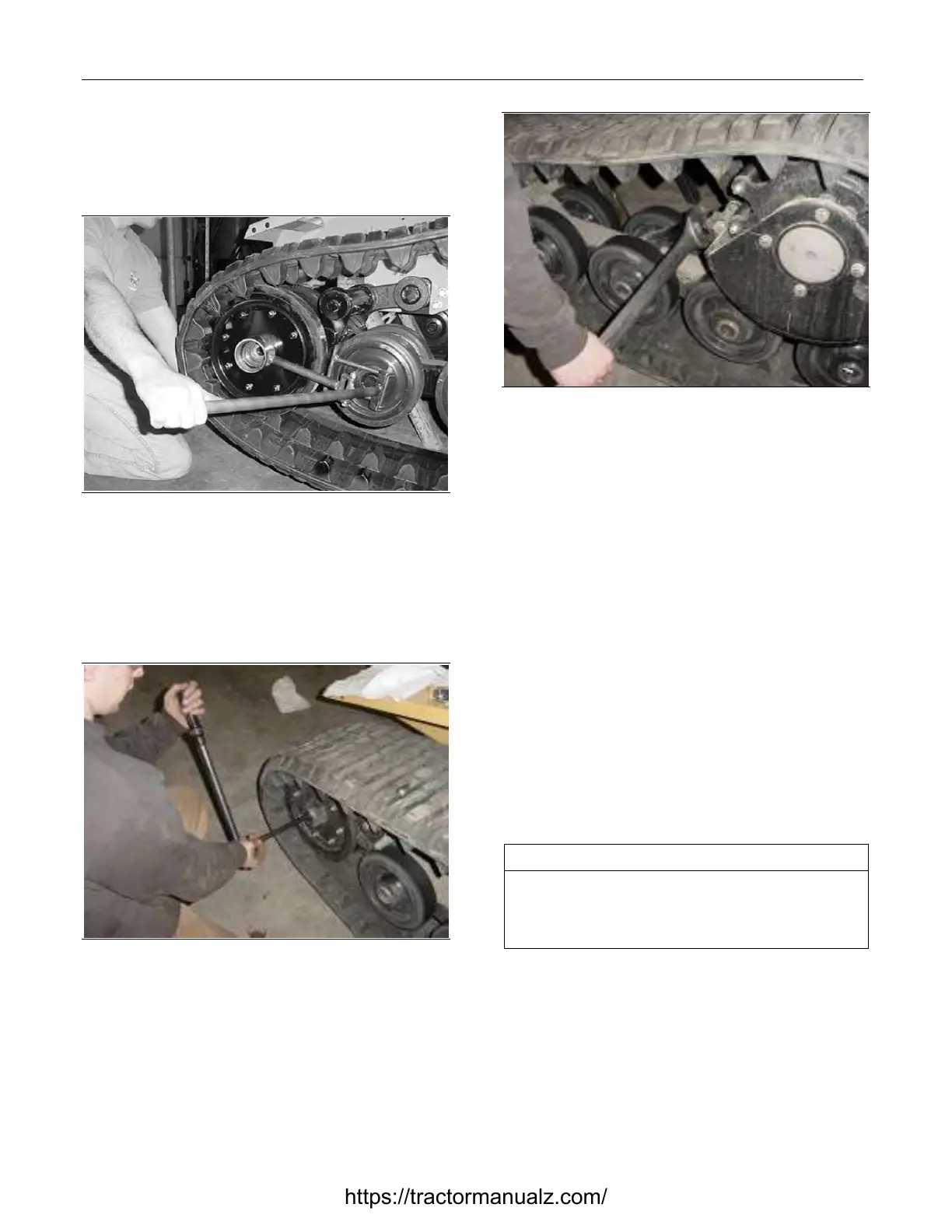

6. Place the wheel between the outside guide lugs

and the inside drive lugs, then pry the wheel

along with the track using the track tool. Line up

the wheel with the shaft and slide the wheel on.

It is very important to use the bullet shaped

thread / seal protector during this procedure.

Figure 0-17 12-054

7. Install the wheel nut and torque to 125 ft.-lbs.

Figure 0-18 12-055

8. Tighten the track by turning the track tensioner.

When proper track tension has been achieved,

tighten the jam nut on the track tensioner.

9. Check for proper track tension. Refer to Chapter

16. Maintenance – Checking for Proper Track

Adjustment

Sprocket Bearing

Removal and Installation

The tools required for sprocket bearing plate

removal and installation are listed in Table 0-4. Use

manufacturer-recommended tools whenever

possible.

Table 0-4

Required Tools

Socket Wrench

Combination Wrench

Snap Ring Pliers

Two pry bars

Sprocket Bearing Plate Removal

1. Remove the track.

2. Remove the soft plug by hitting it with a hammer

and chisel on the very edge.

https://tractormanualz.com/

Loading...

Loading...