Rubber Track Loader

13. Maintenance

13-5

Figure 16-10 16-008

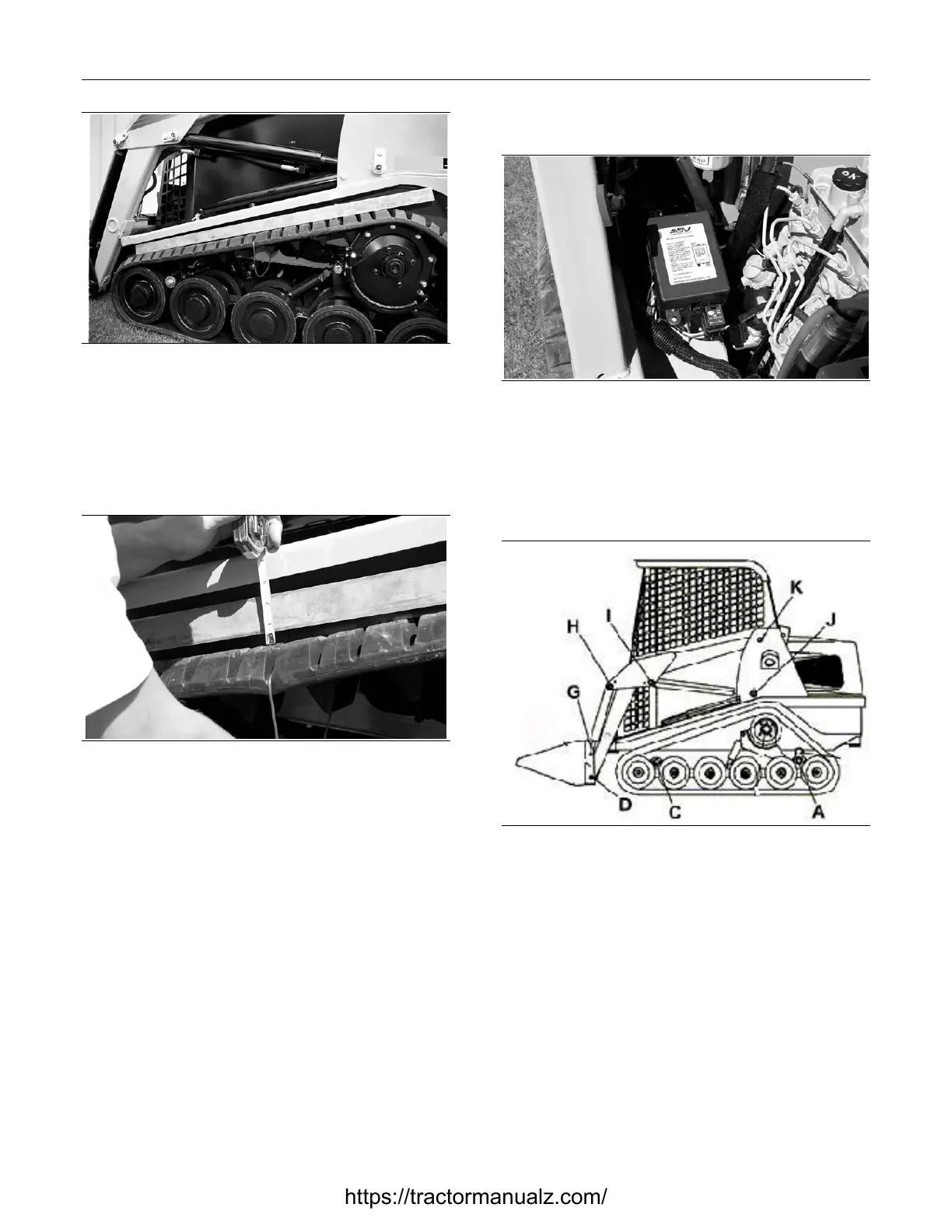

2. Lay a straightedge along the top of the track be-

tween the sprocket and the front idler wheel.

3. Using a rope or wire, put 50 pounds of down

force on the track at the midpoint of the straight-

edge.

Figure 16-11 16-009

4. Using a ruler, measure the distance between the

straightedge and track. The track should not de-

flect more than 0.75” between the top of the

track and the straightedge.

5. If the track deflects more than 0.75”, tighten the

track between 0.50” and 0.75”.

Fuse Box

Figure 16-12 16-012

The fuse box is located on the left side of the engine

compartment. The machine should never be oper-

ated with the fuse box cover removed.

Grease Fittings

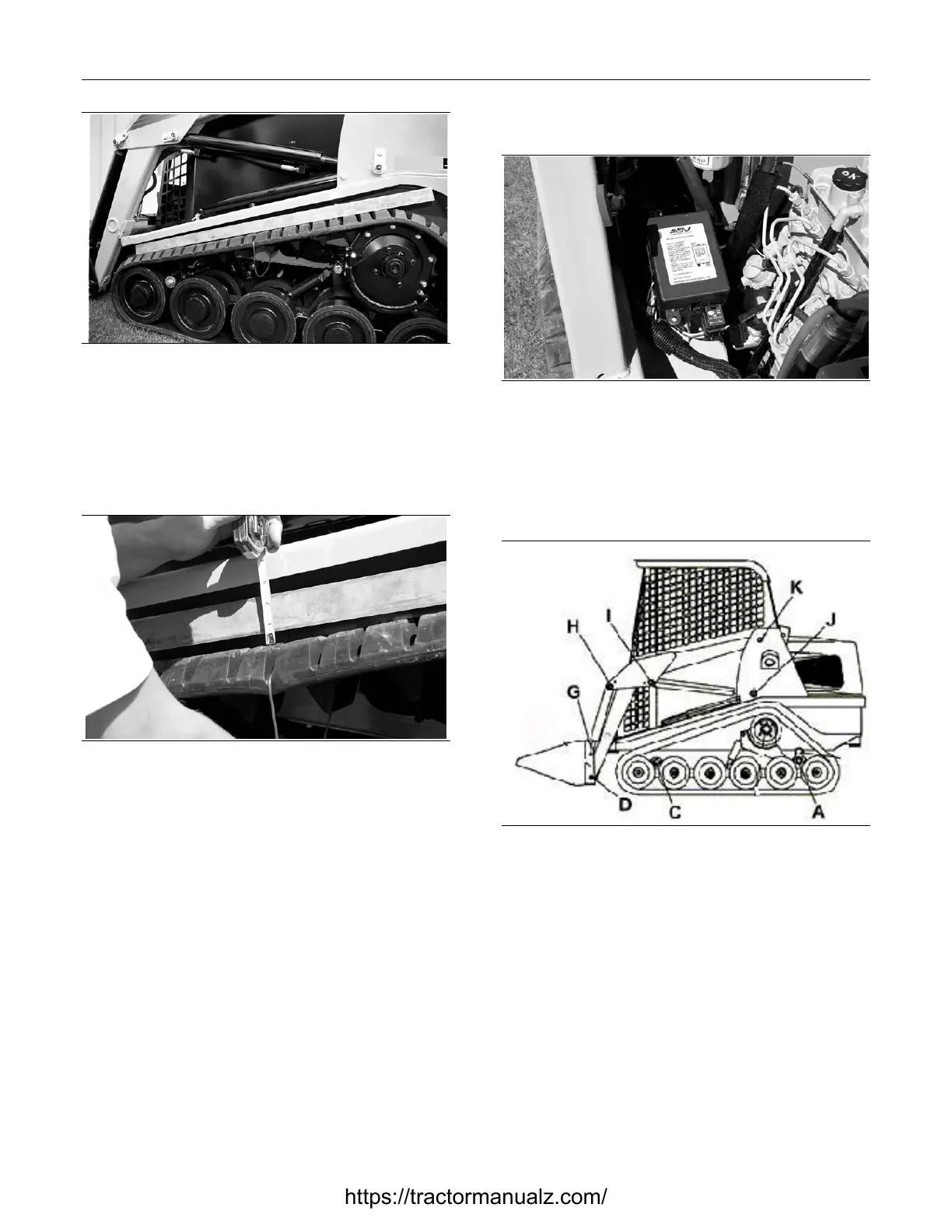

Figure 16-13 16-013

The locations of the grease fittings for the left side of

the machine are shown above. An identical set of

fittings is located on the right side of the machine.

These fitting should be lubricated at least after every

10 hours of operation using Posi-Lube Multi Pur-

pose EP Lithium Grease.

https://tractormanualz.com/

Loading...

Loading...