Chapter 4 – Functions of the instrument

UM-23100B-U User manual ATEQ F CLASS Page 44/90

Associated parameters to be set: Start (Initial value of the transient), Transient (actual

and non modifiable value of the transient), Percentage drift (Drift tolerance on

acquisition of the transient, as a % of the FAIL level).

) Select the option and enter settings if necessary.

9 ATR 2:

The value of the

transient is not

known but the

possible leak of the

part is taken into

account when the

transient value is

computed during

the special cycle.

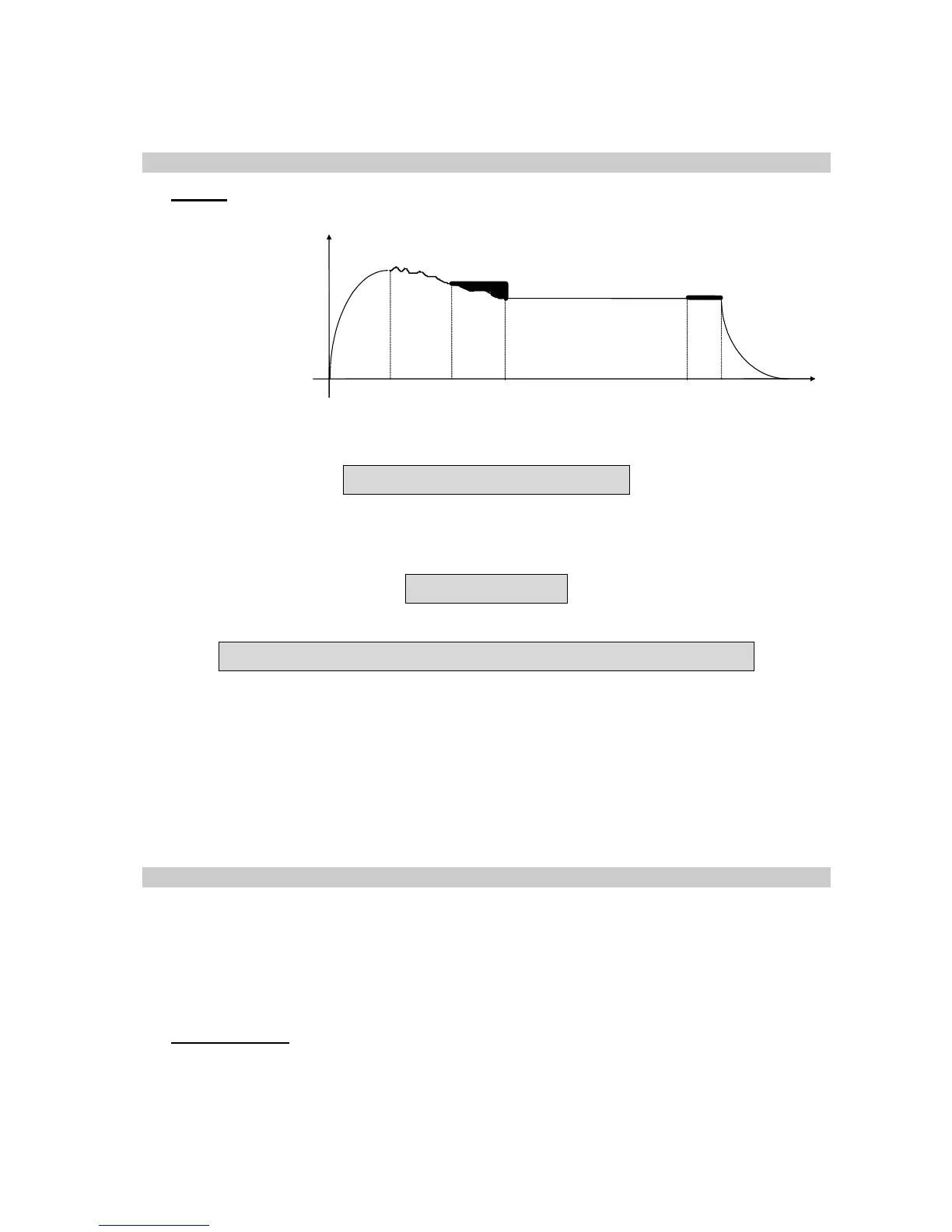

Fill Stab Test1 Wait time 5 x test time Test2 Dump

Time

Pressure

P 1

∆P 2

At the end of test time 1, the ATEQ saves the pressure variation ∆P1, function of the

transient and the leak is there is one.

∆P1 = Leak + Transient

Following the waiting time (equivalent to 5 times the normal test time), we consider that

transient phenomena have disappeared. During the second test time, the ATEQ

instrument reads a second pressure drop ∆P2 which corresponds to the leak.

∆P2 = Leak

By taking these two pressure variations, we can calculate the transient.

∆P1 - ∆P2 = (Leak + Transient) - Leak = Transient

It is this transient which will be taken away from the leak measurement of the following

cycles.

Through the use of the ATR, the ATEQ instrument is able to differentiate a Good

(PASS) part from a Bad (FAIL) part without being influenced by the transient effects

whilst keeping a short stabilisation time.

Associated parameters to be set: Start (Initial value of the transient), Transient (actual

and non modifiable value of the transient), Percentage drift (Drift tolerance on

acquisition of the transient, as a % of the reject level).

) Select the option and enter settings if necessary.

For ATR learning cycles, refer to paragraph 3.3.10 "ATR learning".

When a parameter is modified but no learning cycle has been carried out, an ATR error

occurs. The Alarm and End of Cycle outputs are activated.

Learning may be carried out on a value greater than the reject (FAIL) level and the

Pass and End of Cycle outputs are then activated.

9 Transient drift

Due to the evolution of the test conditions (temperature variations...), the value of the

transient can vary through time. It is therefore necessary to track its evolution.

Loading...

Loading...