Chapter 4 – Functions of the instrument

UM-23100B-U User manual ATEQ F CLASS Page 45/90

To avoid having to carry out learning cycles too often, the ATEQ instrument saves the

last ten values of parts considered as very good (result close to 0) and recalculates the

transient using the average value.

The parts are considered as very good when their leak rate is lower than the

“percentage drift” value of the reject (FAIL) level. This value can be modified between 0

% and 100 %.

10

parts goodvery 10 last the of value the of

Transient

∑

=

The transient attenuation (ATR) can only be used on parts which behave in

very similar ways during the test, in other words, parts which generate similar

transients.

When the batch of parts changes or when the production is stopped for a certain

time, it is necessary to carry out a new learning cycle, as the transient will

change.

The ATR error appears if the difference between the transient and the initial (start)

value is greater than the reject (FAIL) level.

The transient can evolve one way or the other; therefore it is preferable to have identical

Test and Reference reject levels.

2.1.3. 5) Pre-fill mode

This pre-fill function is used in three fields of application:

9 large volume part test : to fill the part faster in order to reduce the cycle time (without

pre-fill time),

9 test on parts requiring a mechanical constraint so that they remain stable for the

duration of the test,

9 part burst tests, where the pre-fill pressure exerts a mechanical constraint similar to

that of a mechanical resistance test on the test part.

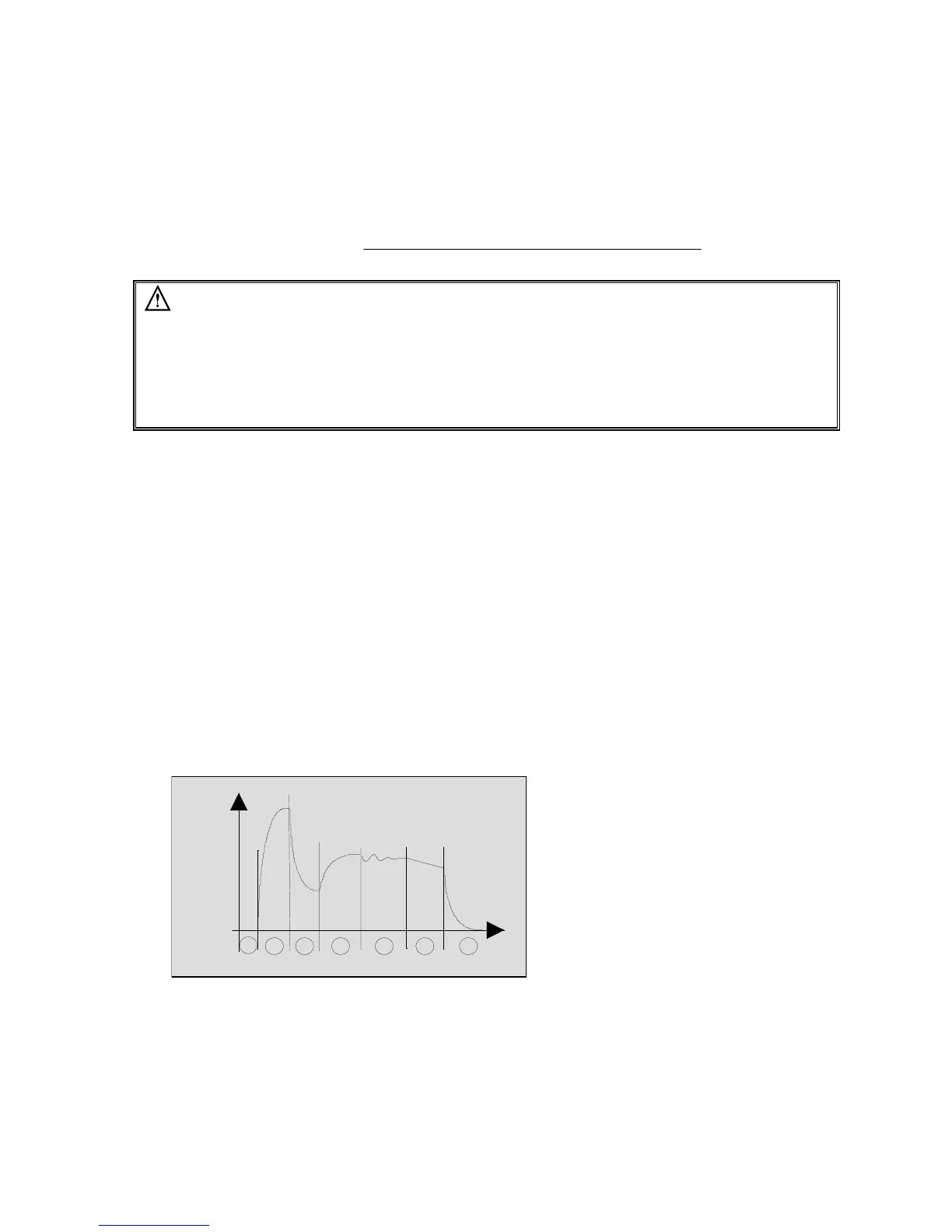

Insertion of the pre-fill and pre-dump times in the measurement cycle.

TEST

PRESSURE

TIME

12

34 5 6 7

1) Wait

2) Pre-fill

3) Pre-dump

4) Fill

5) Stabilisation

6) Test

7) Dump

This function brings up the display of the words “pre reg. adjust” under “Spe. Cycle” so

that the new pressure can be set.

There are several types of pre-fill available.

Loading...

Loading...