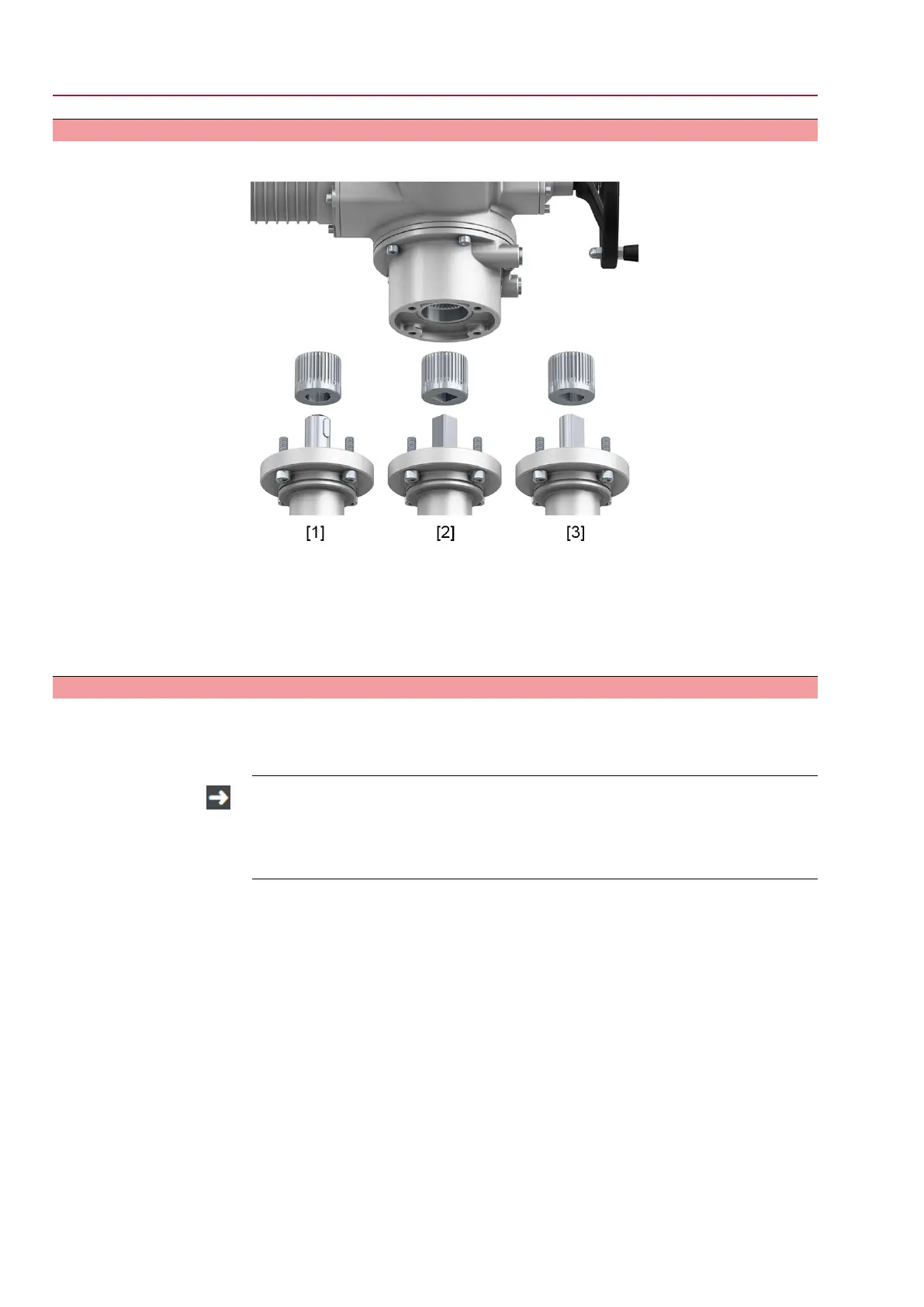

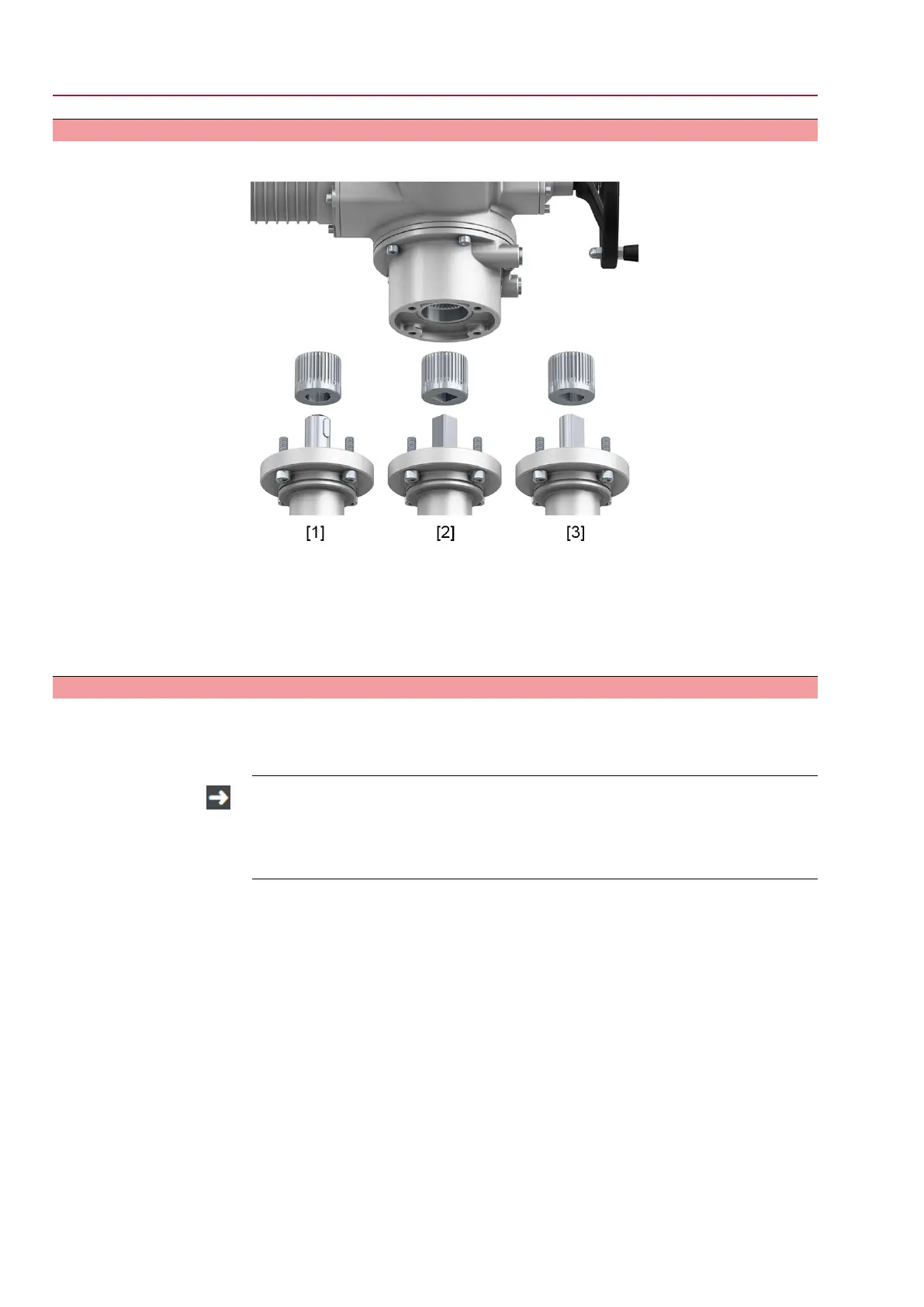

5.3.1. Overview on coupling variants

Design Figure 12:Valve attachment via coupling

[1] Bore with keyway

[2] Square bore

[3] Bore with two-flats

Application

●

For valve attachments according to EN ISO 5211

●

For rotating, non-rising valve stem

5.3.2. Actuator (with coupling): mount

Unbored couplings or couplings with pilot bore must be machined to match the valve

shaft prior to mounting the actuator to the valve (e.g. with bore and keyway, two-flat

or square bore).

Assemble valve and actuator in the same end position. As standard, the actu-

ator is supplied in end position CLOSED.

→

Recommended mounting position for butterfly valves: End position CLOSED.

→

Recommended mounting position for ball valves: End position OPEN.

Assembly steps

1. If required, move actuator in same end position as valve using the handwheel.

2. Clean mounting faces, thoroughly degrease uncoated mounting surfaces.

3. Apply a small quantity of grease to the valve shaft [2].

16

SQV 05.2 – SQV 14.2 / SQRV 05.2 – SQRV 14.2 Control unit: electronic (MWG)

Assembly ACV 01.2 Non-Intrusive Profinet

Loading...

Loading...