Features and functions

●

Selectable type of seating, limit or torque seating for end position OPEN and end po-

sition CLOSED

●

Torque by-pass: Adjustable duration (with adjustable peak torque during start-up time)

●

Start and end of stepping mode as well as ON and OFF times can be set individually

for directions OPEN and CLOSE, 1 to 1,800 seconds

●

Operation profile with any 8 intermediate positions: Position can be set between 0 and

100 %, reaction and signal behaviour programmable

●

Velocity profile with up to 10 ranges, velocity can be individually adjusted for positions

OPEN and CLOSED for each range

●

Running indication blinking: can be set

●

Speed/operating time source can be selected (REMOTE, LOCAL)

●

4 internal nominal speeds or operating times can be programmed (and selected in

LOCAL)

●

Nominal speed source can be selected for REMOTE (binary, analogue, fieldbus)

●

Soft start, soft stop with velocity reduction (adjustable)

●

Positioner:

-

Position setpoint via fieldbus interface

-

Programmable behaviour on loss of signal

-

Automatic adaptation of dead band (adaptive behaviour selectable)

-

Change-over between OPEN-CLOSE control and setpoint control via fieldbus

-

Modulating duty with proportional operation (2 % – 20 %)

Standard:Application functions

●

PID process controller: with adaptive positioner, via 0/4 – 20 mA analogue inputs for

process setpoint and actual process value

●

Automatic deblocking: Up to 5 operation trials, travel time in opposite direction can be

set

Options:

●

Valve overload protection: adjustable, results in switching off and generates fault signal

●

Motor temperature monitoring (thermal monitoring): results in switching off and generates fault indic-

ation

●

Monitoring the heater within actuator: generates warning signal

●

Monitoring of permissible on-time and number of starts: adjustable, generates warning signal

●

Operation time monitoring: adjustable, generates warning signal

●

Phase failure monitoring: results in switching off and generates fault signal

Monitoring function

●

Electronic device ID with order and product data

●

Logging of operating data: A resettable counter and a lifetime counter each for:

-

Motor running time, number of starts, torque switch trippings in end position CLOSED, limit

switch trippings in end position CLOSED, torque switch trippings in end position OPEN, limit

switch trippings in end position OPEN, torque faults CLOSE, torque faults OPEN, motor protection

trippings

●

Time-stamped event report with history for setting, operation and faults:

-

Status signals according to NAMUR recommendation NE 107: "Failure", "Function check", "Out

of specification", "Maintenance required"

●

Torque characteristics (for version with MWG in actuator):

-

3 torque characteristics (torque-travel characteristic) for opening and closing directions can be

saved separately.

-

Torque characteristics stored can be shown on the display.

Diagnostic functions

Monitoring the motor temperature in combination with thermoswitches within actuator

motor

Standard:Motor protection evaluation

PTC tripping device (TMS module) in combination with PTC thermistors within actuator

motor

Option:

AUMA plug/socket connector with screw-type connectionStandard:Electrical connection

●

Terminals or crimp connection

●

Gold-plated control contacts (pins and sockets)

Options:

Metric threadsStandard:Threads for cable entries

Pg-threads, NPT-threads, G-threadsOptions:

Refer to name plateWiring diagram

78

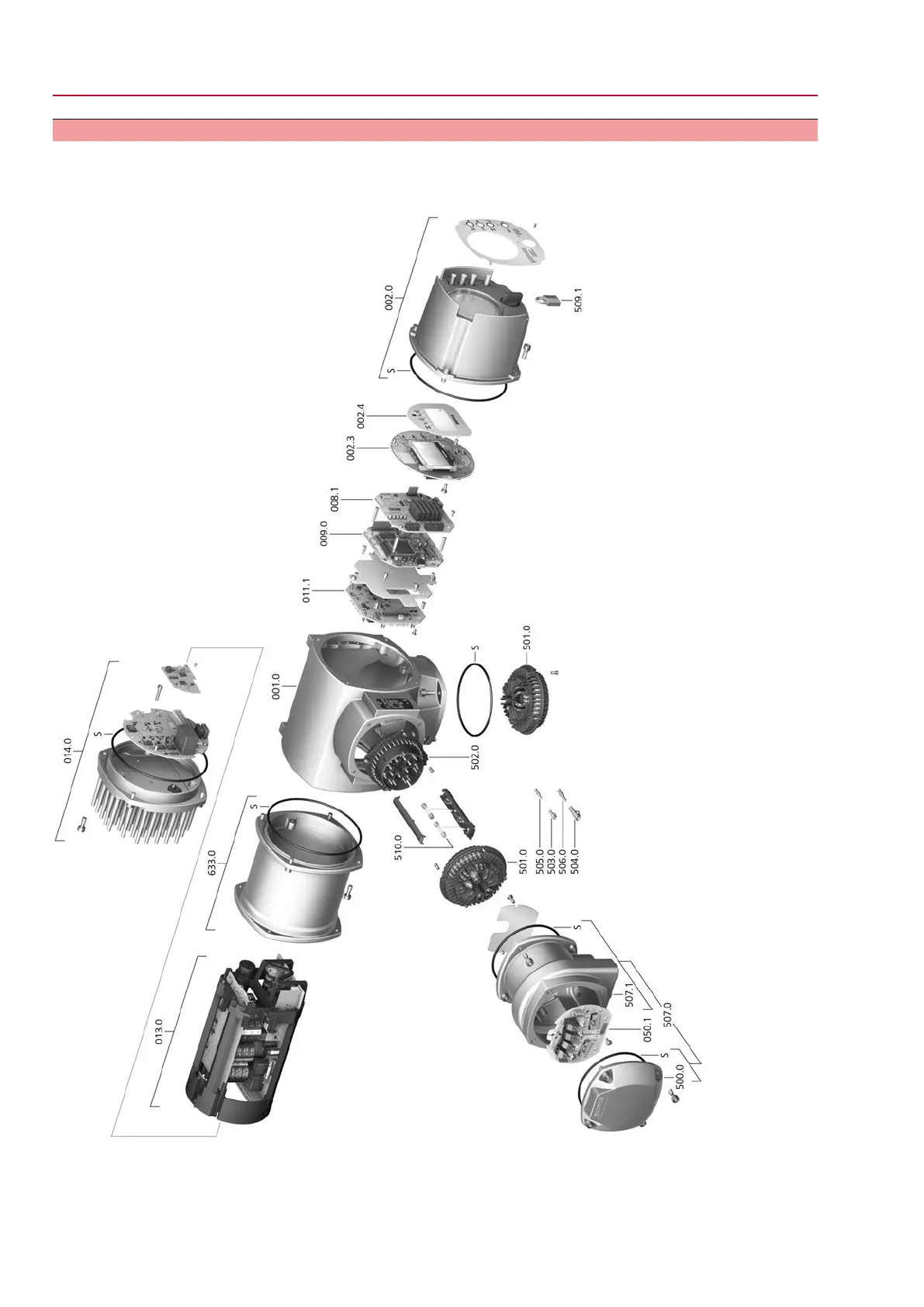

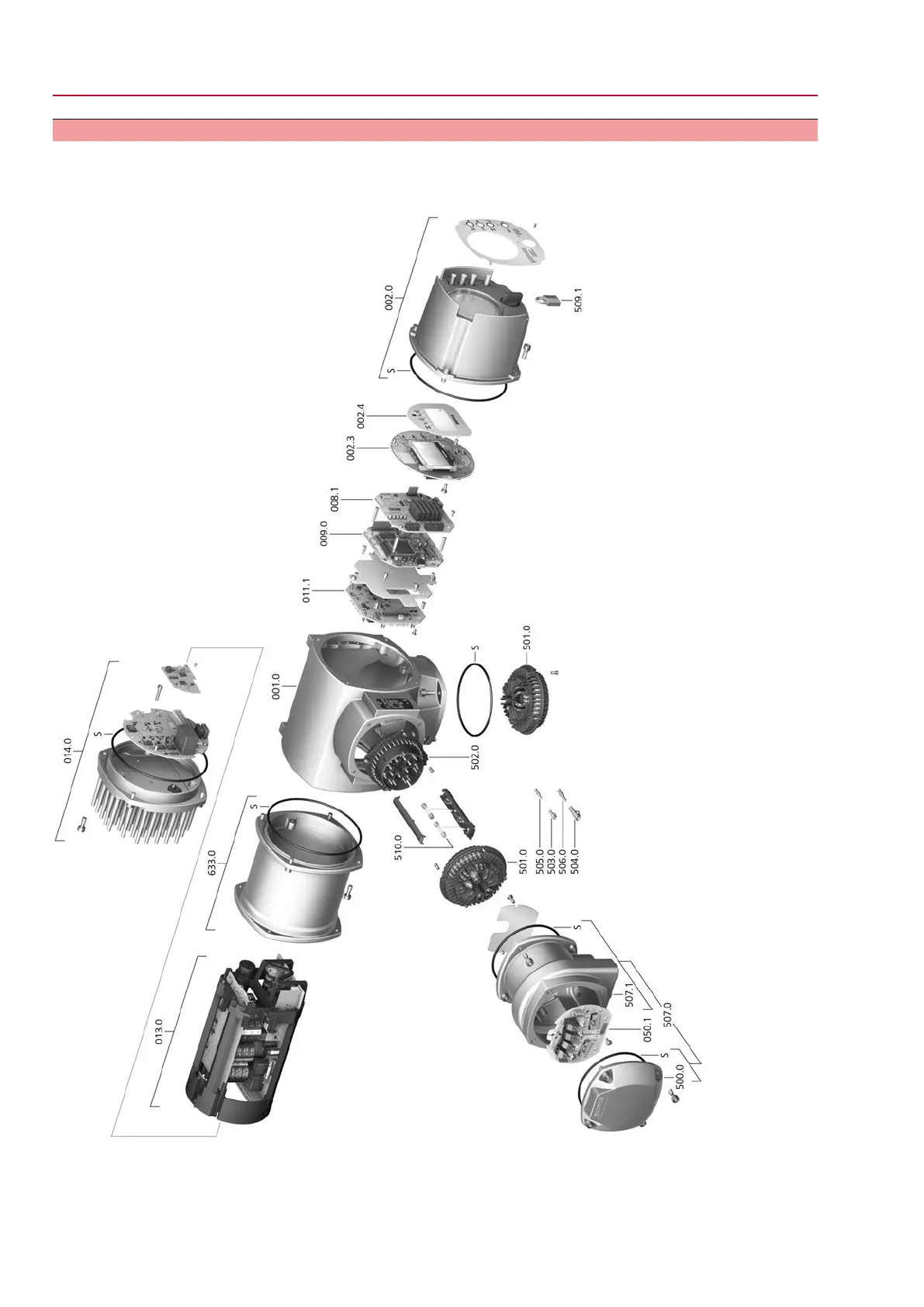

SQV 05.2 – SQV 14.2 / SQRV 05.2 – SQRV 14.2 Control unit: electronic (MWG)

Technical data ACV 01.2 Non-Intrusive Profinet

Loading...

Loading...