6.2.1. Terminal compartment (for mains connection): open

Figure 20: Open mains terminal compartment

[1] Connection housing

[2] Screws for frame

[3] O-ring

[4] Screws for socket carrier

[5] Socket carrier

[6] Cable entries for mains connection (power and control contacts)

[7] Blanking plug

[8] Cable gland (not included in delivery)

Electric shock due to presence of hazardous voltage!

Failure to observe this warning results in death or serious injury.

→

Disconnect device from the mains before opening.

→

Wait for 30 seconds after power cut-off prior to opening the housing.

1. Loosen screws [2] and remove connection housing [1].

2. Loosen screws [4] and remove socket carrier [5] from connection housing [1].

3. Insert cable glands [8] suitable for connecting cables.

➥

The enclosure protection IP… stated on the name plate is only ensured if suit-

able cable glands are used.

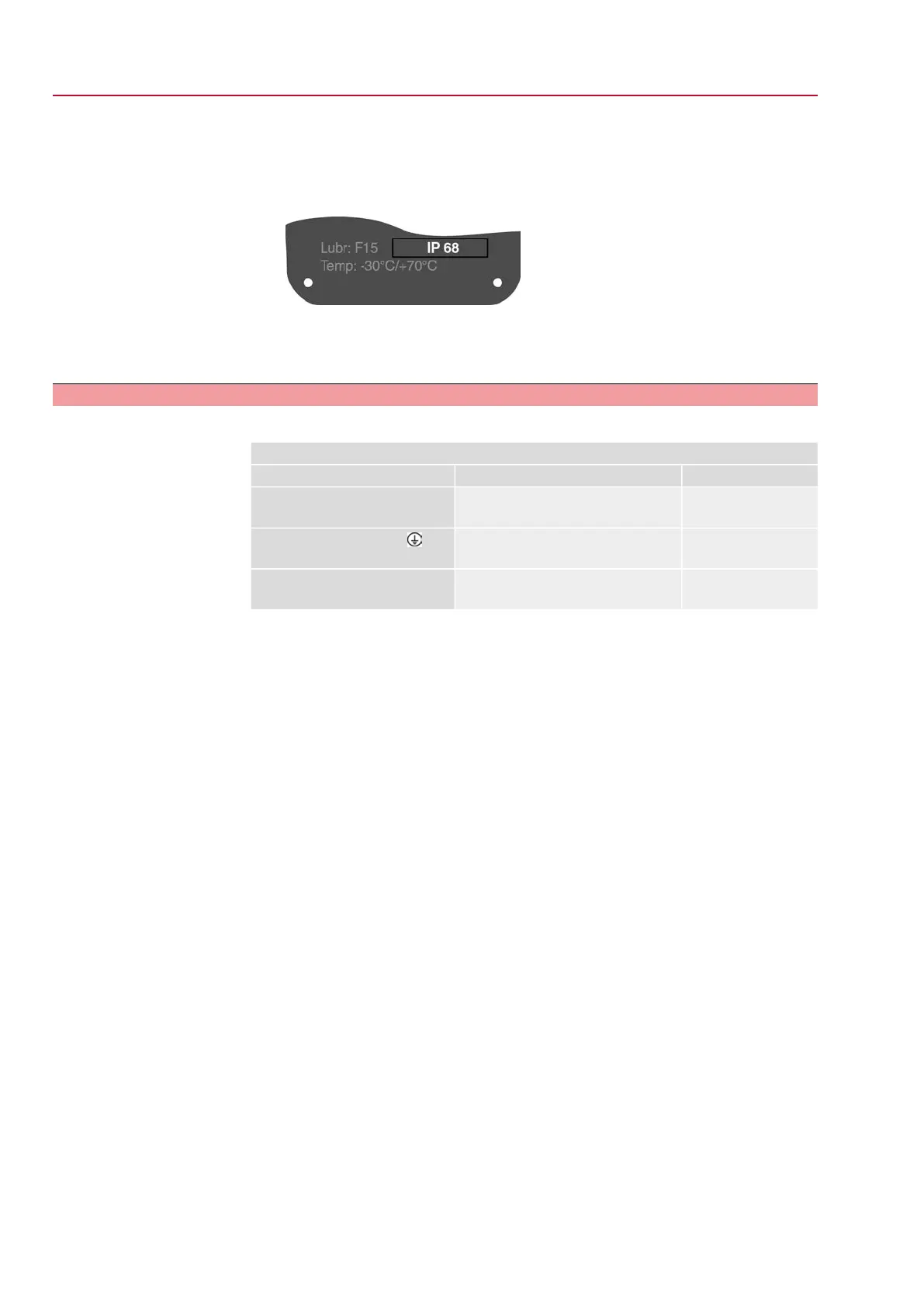

Figure 21: Example: Name plate for enclosure protection IP68

4. Seal unused cable entries [6] with suitable blanking plugs [7].

Information

Fieldbus connection can be accessed separately from the mains connection (refer

to <Fieldbus terminal compartment: open>.

24

SQV 05.2 – SQV 14.2 / SQRV 05.2 – SQRV 14.2 Control unit: electronic (MWG)

Electrical connection ACV 01.2 Non-Intrusive Profinet

Loading...

Loading...