METER GASKETS AND GROUNDING

Gaskets and grounding are required for proper meter installation.

IMPORTANT

If you received grounding rings with your meter, install them. Electromagnetic meters require a good ground for proper operation.

Grounding rings also help protect the edge of the liner from debris that may flow from the pipe.

Meter/Pipeline Connection Gaskets

IMPORTANT

It is essential that the transmitter’s input ground (zero voltage reference) be electrically connected to the liquid media and to a good,

solid earth ground reference.

You must install gaskets (not provided) between the sensor's

isolating liner, grounding rings and the pipeline flange to provide a

proper and secure hydraulic seal. Use gaskets that are compatible

with the fluid. Center each gasket on the flange to avoid flow

restrictions or turbulence in the line.

During installation, do not use graphite or any electrically

conductive sealing compound to hold the gaskets. This could

compromise the accuracy of the measuring signal.

If you are using a grounding ring in the sensor/pipeline connection,

place the ring between two gaskets. See “Recommended Installation

with Grounding Rings” on page 16 for more instructions.

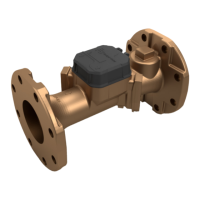

GROUNDING RING

GROUNDING RING

Figure 15: Meter/pipeline connection gaskets and grounding rings

Meter Grounding and Potential Equalization

In order to obtain an accurate measurement, sensor and fluid need to be on the same electric potential.

Process pipeline material can be either electrically conductive (metal) or not electrically conductive (made of or lined with

PVC, fiberglass or concrete).

If flange or intermediate flange versions with additional grounding electrode are used, grounding is provided by the

connected pipeline.

IN CASE OF A TYPE WITH FLANGE, USE A CONNECTION CABLE (MINIMUM 4 MM²) BETWEEN GROUNDING SCREW

ON THE METER FLANGE TO THE COUNTERFLANGE IN ADDITION TO THE FIXING SCREWS. VERIFY THAT A PERFECT

ELECTRIC CONNECTION IS PROVIDED.

COLOR OR CORROSION ON THE COUNTERFLANGE MAY HAVE A NEGATIVE EFFECT ON THE ELECTRIC CONNECTION.

IN CASE OF TYPES WITH INTERMEDIATE FLANGES, THE ELECTRIC CONNECTION TO THE SENSOR IS DONE VIA TWO 1/4

AMP PLUGS INSTALLED ON SENSOR’S NECK.

Meter Gaskets and Grounding

Page 15 March 2022 MAG-UM-01272-EN-21

Loading...

Loading...