UNPACKING AND INSPECTION

Follow these guidelines when unpacking the equipment.

• If a shipping container shows any sign of damage, have the shipper present when you unpack the meter.

• Follow all unpacking, lifting and moving instructions associated with the shipping container.

• Open the container and remove all packing materials. Store the shipping container and packing

materials if the unit needs to be shipped for service.

• Verify that the shipment matches the packing list and your order form.

• Inspect the meter for any signs of shipping damage, scratches, or loose or broken parts.

OTE: N If the unit was damaged in transit, it is your responsibility to request an inspection report from the carrier within

48 hours. You must then file a claim with the carrier and contact BadgerMeter for appropriate repairs or replacement.

• All sensors with polytetrafluoroethylene (PTFE) liners are shipped with a liner protector on each end to maintain proper

form of the PTFE material during shipping and storage.

• Do not remove the liner protectors until you are ready to install.

OTE: N Storage: If the meter is to be stored, place it in its original container in a dry, sheltered location.

Storage temperature ranges are: –40…160° F (–40…71° C).

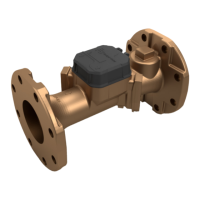

Rigging, Lifting and Moving Large Units

WHEN RIGGING, LIFTING OR MOVING LARGE UNITS, FOLLOW THESE GUIDELINES:

• DO NOT lift or move a meter by its transmitter, junction box, sensor neck or cables.

• Use a crane rigged with soft straps to lift and move meters with flow tubes that are 2…8 inches (50…200 mm). Place the

straps around the sensor body, between the flanges, on each side of the sensor.

• Use the lifting lugs when lifting meter flow tubes that are 10 inches (250 mm) in diameter or larger.

Place straps between flanges Use lifting lugs with 10 inch or larger meters

Figure 2: Rigging large units

Unpacking and Inspection

Page 7 March 2022 MAG-UM-01272-EN-21

Loading...

Loading...