MAINTENANCE

Mandatory, routine or scheduled maintenance should not be required for the M2000 meter electronics or flow tube after

proper installation.

However, some instances may require you to perform the following:

• Flow tube and electrode cleaning

• Fuse replacement

• Circuit board replacement

• DISCONNECT MAIN POWER TO THE UNIT BEFORE ATTEMPTING ANY DEVICE MAINTENANCE OR CLEANING.

• DO NOT CLEAN COMPONENTS INSIDE THE AMPLIFIER OR JUNCTION BOX.

• CLEAN USING A DAMP CLOTH. DO NOT USE LIQUID OR AEROSOL CLEANERS.

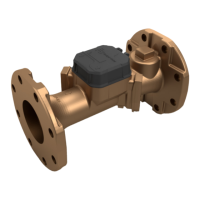

Cleaning the Flow Tube and Electrode

At times flow tube, electrodes, transmitter/junction box housings and the transmitter window may need periodic cleaning,

depending on process fluid properties, fluid flow rate and surrounding environment.

Clean the flow tube and electrodes by following the material handling and cleaning procedures documented in Material

Safety Data Sheet (MSDS) guidelines for the product(s) that were in contact with the flow tube and electrodes.

Should flow tube and/or electrode cleaning become necessary:

1. Disconnect sensor from pipeline.

2. Clean electrodes according to MSDS guidelines.

3. Reconnect sensor to pipeline.

Replacing the Circuit Board

Refer to the M2000 Interchangeability Procedure Application Brief for information on replacing circuit boards.

Replacing the Fuse

DISCONNECT MAIN POWER TO THE UNIT BEFORE ATTEMPTING ANY DEVICE MAINTENANCE. RISK OF ELECTRICAL

SHOCK. REPLACE THE FUSE ONLY WITH 250V AC, 2 AMP, SLOW BLOW (5 × 20 MM). AUTHORIZED PERSONNEL MUST

REPLACE FUSES.

Fuse type: T2 H 250 V (2A idle)

L

N

Figure 39: Fuse

Maintenance

Page 60 March 2022MAG-UM-01272-EN-21

Loading...

Loading...