14. Maintenance procedures

14.4 Washing and drying the dust filters

About filter washing and drying

For environments where p opcorn g rease and s uch can contaminate the filters, Barco advises the client to purchase one extra sets

of filters to cover drying time, as well as taking following extra precautions and instructions pertaining to filter cleaning and drying.

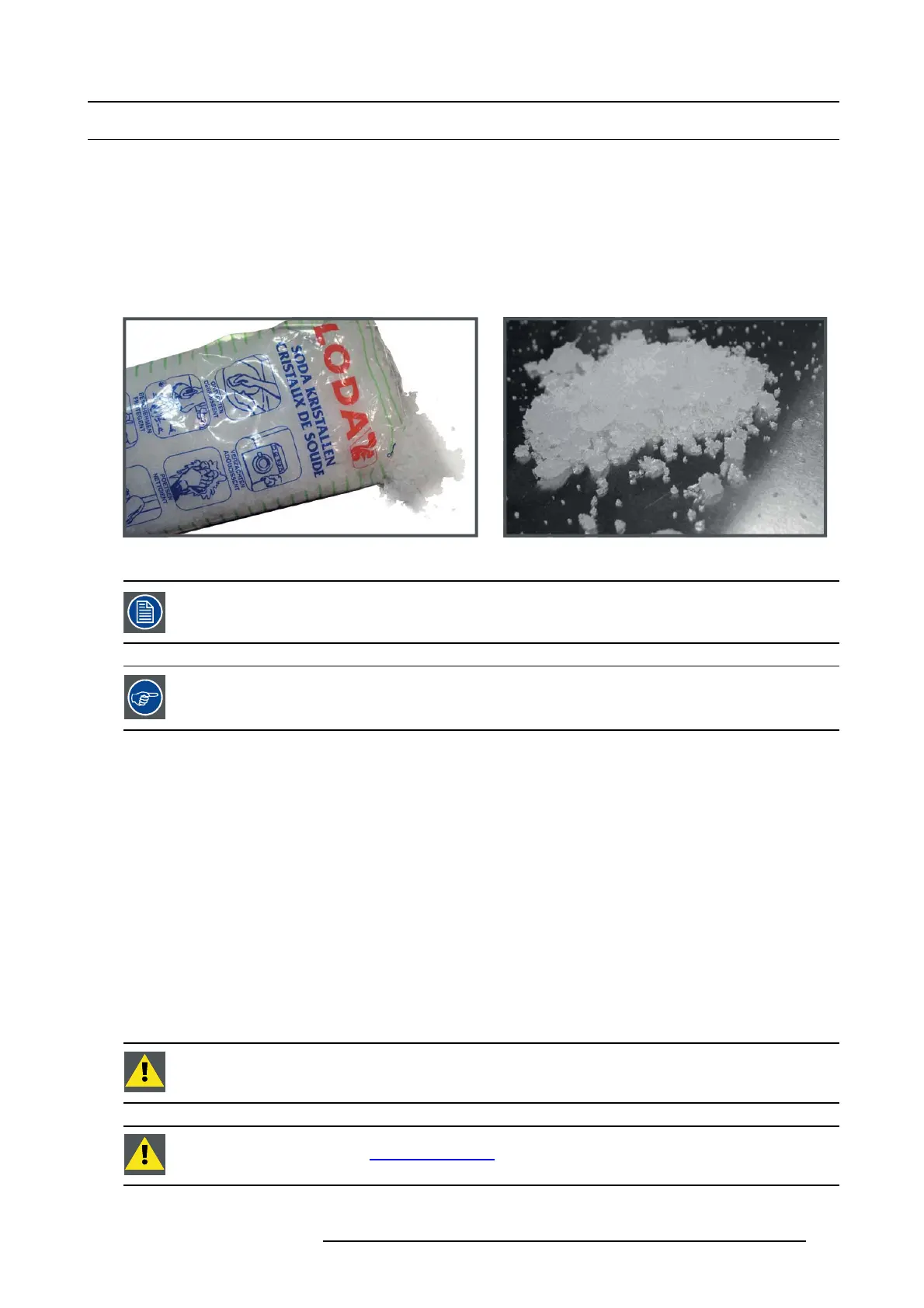

Cleansing agent

To clean sticky, greasy dust filters we suggest usage of Sodium carbonate crystals (Na

2

CO

3

). Sodium carbonate (Often called

washing soda, soda crystals,orsal sod a in the detergent section o f s tores) is widely used to effectively remove oil, gr ease, alcohol

stains … T he product itself is relatively safe, sodium carbonate is used in toothpastes and as a food additive (E500). Potential

Hazards are described in the section "Hazards", page 145.

Image 14-5

Sodium carbonate crystals.

This cleaning procedure assum es that the filters are alread y removed from the p rojector.

Take into acco unt that the time needed to dry the du st fi lters may be 24 hours or more. For that, it’s recom-

mended to have a second set of dust filters which can be use

d w hile cleaning the first set.

Necessary tools

• Bucket with hot water.

• Sodium carbonate, 30 gram (handful) per liter hot water.

How to wash and dry the dust filters?

1. M ake a solution with a ratio of 30 gram (a handful) sodium carbonate to 1 liter hot water.

2. Soak the dust filters in the solution for 30 to 60 m inutes. The grease should be dissolved after 1 hour.

3. If the dust filter is still clogged repeat this procedure from step 1.

4. R inse the dust filters with clean water to flush all grease residue away.

5. Shake out all excess liquid by repea tedly swinging the filter to-and-fro in a centrifugal action.

6. Then allow the filters to dry thoroughly. Ty pically this can take up t o 2 4h and m ore, depending on the drying c onditions.

Note: Drying time of the dust fi lters can be u p to 24h or more. Drying time can be shorter when being done in a w ell-ventilated

area.

Tip: To speed-up drying, allow the fi lt e r(s) to

dry at 50°C m ax in a well ventilated room.

CAUTION: UNDER NO CIRCUMSTANCES S HOULD WET FILTERS BE INSTALLED BACK INTO THE PROJEC -

TOR. THIS CA N HAVE SERIOUS SAFETY CONSEQUENCES AS WELL AS JEOPARDIZE THE INTERNAL OP-

TICS OF THE SYSTEM.

CAUTION: Do not install/use damaged dust filters. Replace d amag ed dust filters immediately with new dust

filters of t he sam e type. See h

ttps://my.barco.com for replacement part

R5977692 DP2K-S SERIES 10/12/2012 111

Loading...

Loading...