© BEKA 2019 All rights reserved! -48-

Insert new cartridge and ventilate device

Lubricant cannot be conveyor

Use lubricant with correct viscosity

Supply interrupts but

drive is ok

Wear on the non-return valve in the

pump element

Change non-return valve (see chapter 12.3 “Change of

the non-return valve” and 17. “Spare parts”)

Cartridge connection leaky

Retighten cartridge, possibly change sealing washer or

cartridge

Insert new cartridge and ventilate device

Device supplies without

or with low pressure

Wear on the non-return valve in the

pump element

Change non-return valve (see chapter 12.3 “Change of

the non-return valve” and 17. “Spare parts”)

Pressure limiting valve does not close

Exchange pressure limiting valve

15.1 Signal displays of the control

The device signals a malfunction when the errors E1 to E5 are displayed.

With the errors E1, E2, E3 and E4, the signal display goes out automatically after eliminating the cause of error.

The error E5 must be reset as described in chapter 15.2 “Resetting the error E5”.

In general, an intermediate lubrication should be triggered after eliminating any cause of error in order to test

the faultless function of the device (see also chapter 10.2 “Intermediate lubrication”).

LED glows LED flashes

Device active

o The device is operational

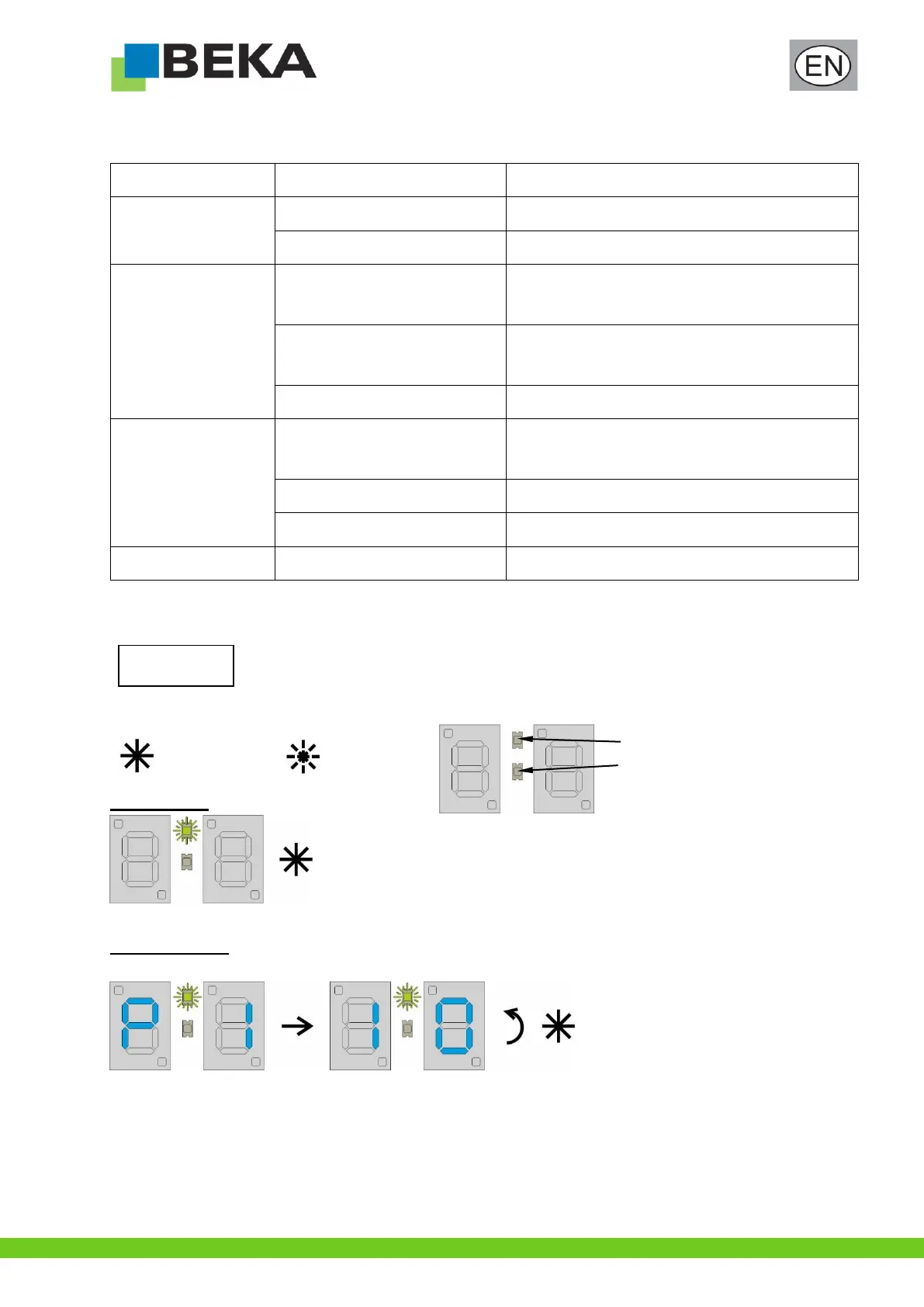

Device operates

Display sequence:

(Program) (Lubrication (Cycle

duration) duration)

o The device performs a lubrication

Loading...

Loading...