5

Screws of explosion-proof actuator body must be of a minimum 8.8 quality grade or made of

stainless steel with a minimum 70 daN/mm2 tensile strength. In case of use in explosive dust

atmosphere, check that cover tightness gaskets are intact and make sure not to degrade the gas-

kets while closing the cover. Cable entries shall provide a level of protection equal or higher than the

one indicated on the actuator identification plate. The user shall ensure a regular cleaning of the product

housing to avoid dust build-up.

Overheating

A motor thermal protection switch is (refer to actuator electric diagram) integrated into the motor

control circuit in order to switch off the motor power supply in case of overheating conditions. This

protection is mandatory to respect maximum surface temperatures.

Cable entries

Check that cable glands are used and wiring done according to the explosion-proof equipment standards ;

take a special care of the compatibility between the cable diameter and the cable gland size. If one

of the cable entries is not used, seal it with a certified metal plug and without adapter.

If an adapter is necessary to fit a cable gland, only one is allowed by cable entry and use a certified one.

The actuator is delivered with a yellow sticker, in the connection compartment, that obstruates the cable

entries. The danger symbol

and a notice warns the installer of the obligation to equip each cable entry

with a certified plug or cable gland.

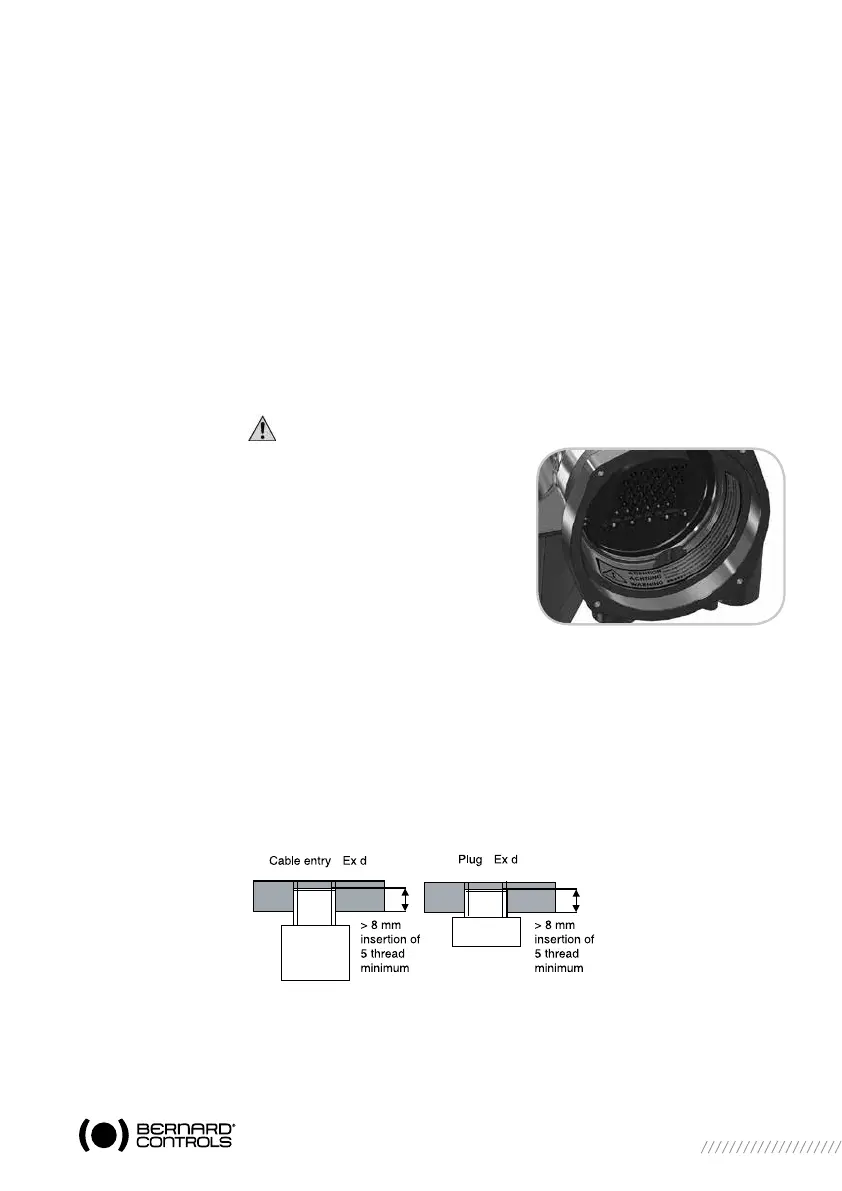

For cable gland and plug take care of the marking:

ATEX : Exd (or Exe in case of an increased safety « e » connexion

compartment)

IECEx : Exd (or Exe in case of an increased safety « e » connexion

compartment)

IEx : Brazilian certification Exd.

For Exd box, the thread type is indicated in the connection box to avoid confusion (NPT or ISO).

If the ambiant temperature exceeds 60°C, consider an additional 10°C at the cable entry. I.e, at a maximum

ambiant temperature of 70°C, the temperature at the cable entry will be 80°C.

Terminal compartment with double double-sealing protection and volume < 2 liitres.

Wiring

Maximum acceptable voltage for the power supply terminal (M4) is 690V and 160V for control terminals

unless otherwise specified on the wiring diagram. Connection is done with isolated and crimped ring tongue

terminals. The maximum cable section is 6mm2 for the power supply (M4) and 4mm2 for controls (M3).

An external earth rod allows connection to the earth (4 mm

2

for stranded, 6mm

2

single wire, on request up

to 35mm

2

). Make sure to wire both internal and external groundings.

Water-proofness

Because the NPT cable gland thread is not IP68, it’s necessary to mount it with a thread sealant for ex: Loctite

577 (Henkel). In case of ISO thread, sealing is assured by an O ring or by a thread sealant as noticed above.

Please note : For Exd enclosure, thread type (NPT or ISO) is indicated in the connection box to avoid any mistake.

Loading...

Loading...