BestCode Next Series 8 Technical Manual October 2022 Page 207 of 290

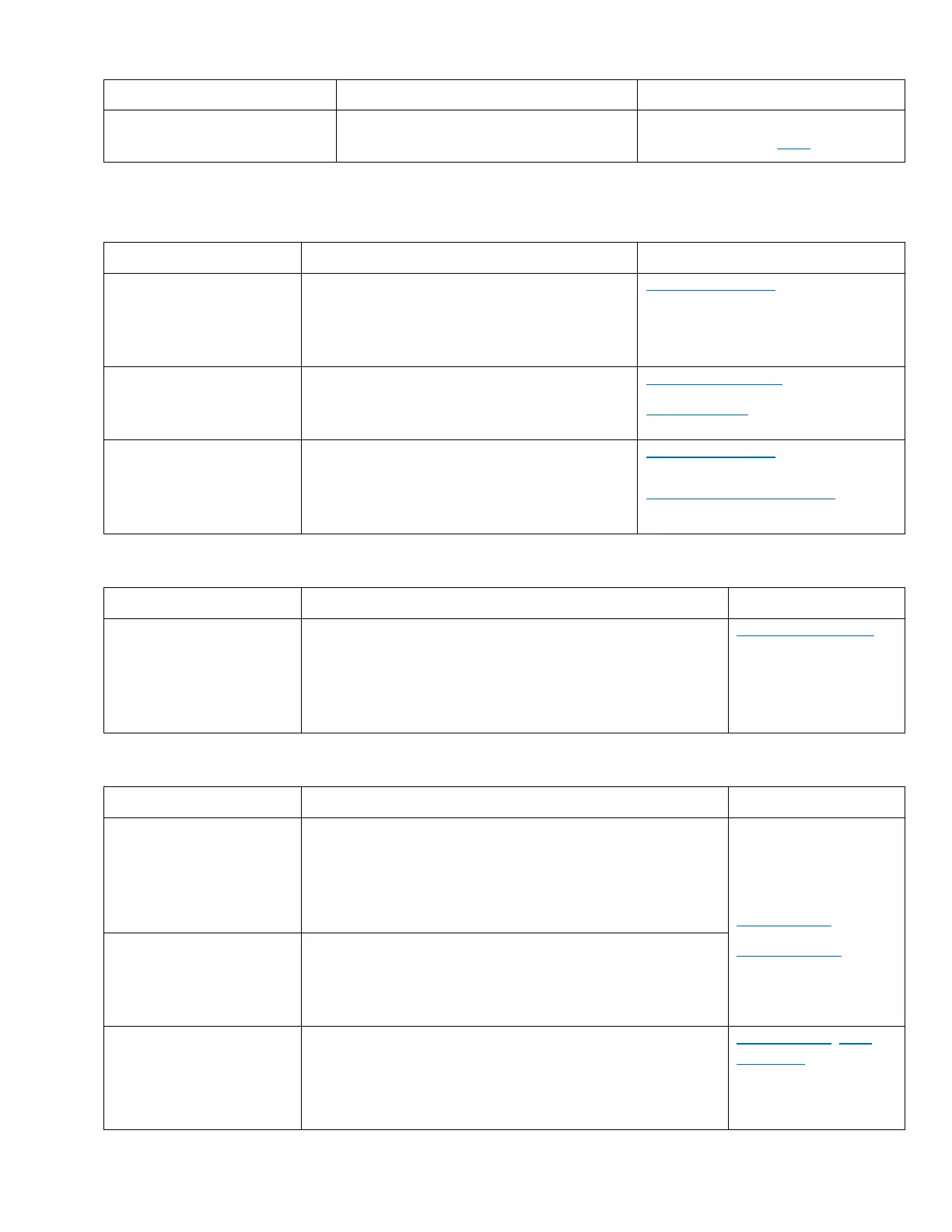

Wrong pump configuration

The software setting for Pump type does not

match the pump installed in the machine

Change pump type to match the

installed pump. See here.

Viscosity Fault

Low vacuum venturi

Dried ink or debris are stuck in the venturi causing

low vacuum. Makeup is not able to be drawn ink

the ink tank fast enough to maintain adequate

viscosity.

Venturi orifice is poorly adjusted. Makeup is not

able to be drawn ink the ink tank fast enough to

maintain adequate viscosity.

Replacing the Venturi

Test the Venturi

Venturi vacuum inlet

restricted

Venturi inlet ports are restricted. Makeup is not

able to be drawn ink the ink tank fast enough to

maintain adequate viscosity.

Cleaning the Venturi

Review components and tubing in the

Standard Run Operation chart on the

vacuum gutter and makeup add line.

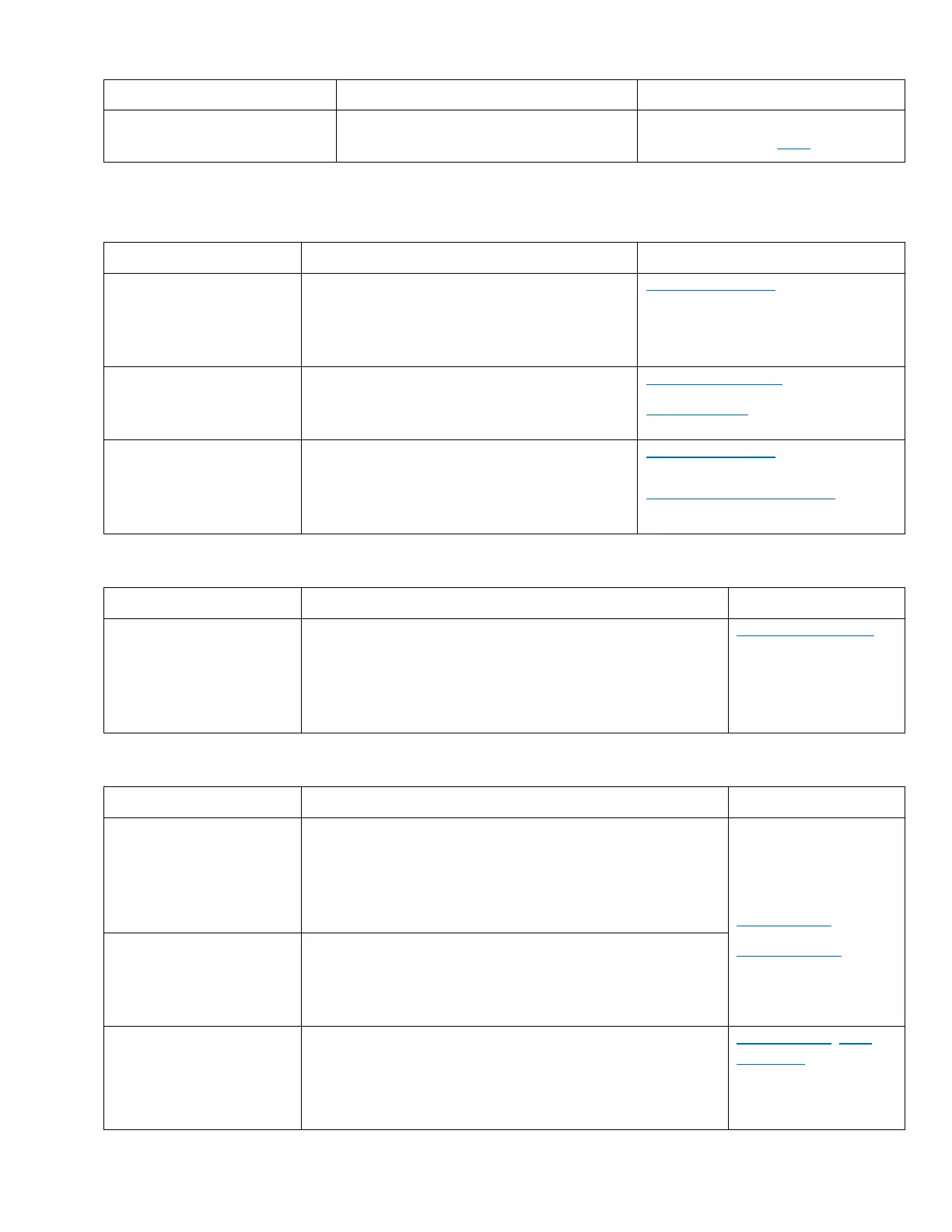

Machine is set to to the

wrong Gen Setting

Gen 1 Printers must have software configured to Gen 1, and Gen

2 Printers must have software configured to Gen 2. The two

generations use different valve control and having them set

incorrectly can allow Makeup to be rapidly added to the Ink

tank.

Ink types have been mixed

Typically occurs when SmartFill process is not followed or when

a system is not flushed well enough between ink type change

overs. Mixed ink types will produce a very thick residue on

bottom of ink tank. This will gum up the viscometer preventing

good reads.

Dump Ink Tank

Flush the Printer

The wrong solvent type was used to perform manual cleanings

on the head or other components. Continued use of wrong

cleaner type can cause residue to form in the Ink Tank. This will

gum up the viscometer preventing good reads.

A humid environment can allow more rapid concentrations of

water in the ink to occur, leading to thick and potentially jelly

like consistency. This will gum up the viscometer preventing

good reads.

Dump Ink Tank, Flush

the Printer,

Install -DRY kit to reduce

water ingress to the ink.

Loading...

Loading...