3

51

A

ENGINE CHECKS AND ASSEMBLY

3.2 CONNECTING ROD AND

ENGINE SHAFT CHECK

3.2.1 Slew bearing removal and

refitting

If the main bearings need to be replaced, for the

250 ONLY, the main slew bearing on the left hand

motor semi-axle must also be replaced.

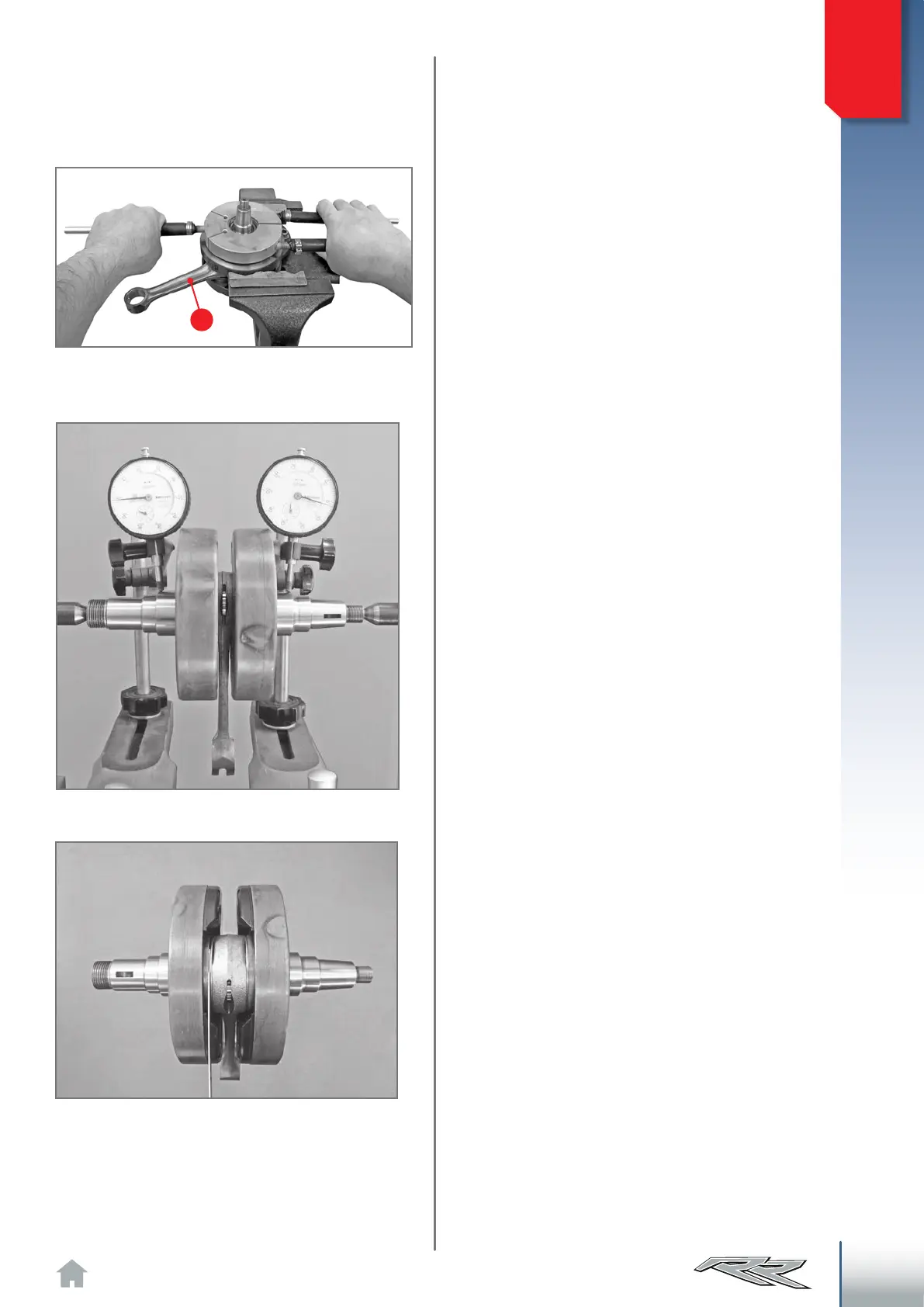

To do this, clamp the drive shaft of the semi-axle

on which the slew bearing to be replaced is in a

vice. Using an electric hotplate, heat special tool

A (code 026.14.018.00.00) to around 150°C and

put it on to the slew bearing straight away.

Hold the special tool tight to maintain good heat

transmission and pull out the slew bearing.

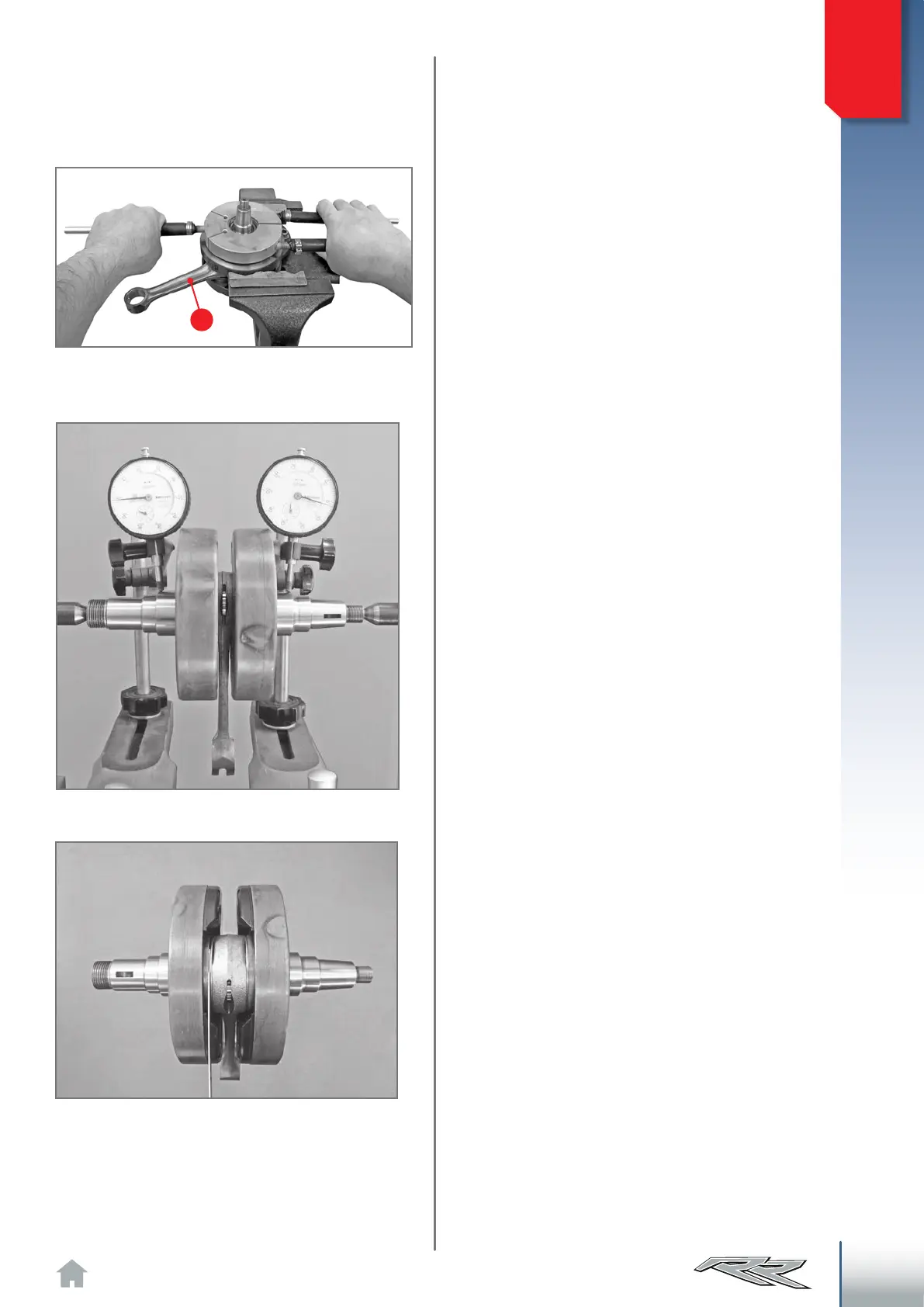

After checking the state of wear of the mating

surfaces, check the offset of the half shaft axes

(by measuring radial oscillation) by placing the

crankshaft between two tailstocks or similar

instrument. Check the maximum measurement

variation during a complete turn, using

comparators positioned on the mating surfaces

with the crankshaft bearings.

Allowed limit value: 0.02mm

Check the axial play between the connecting rod

head and the half shafts.

Recommended play:

0.39÷0.72mm

Remove the slew bearing from the right hand

semi-axle on the 250 version.

Deflection/Off-centring of crankshaft.

Connecting rod axial play.

Loading...

Loading...