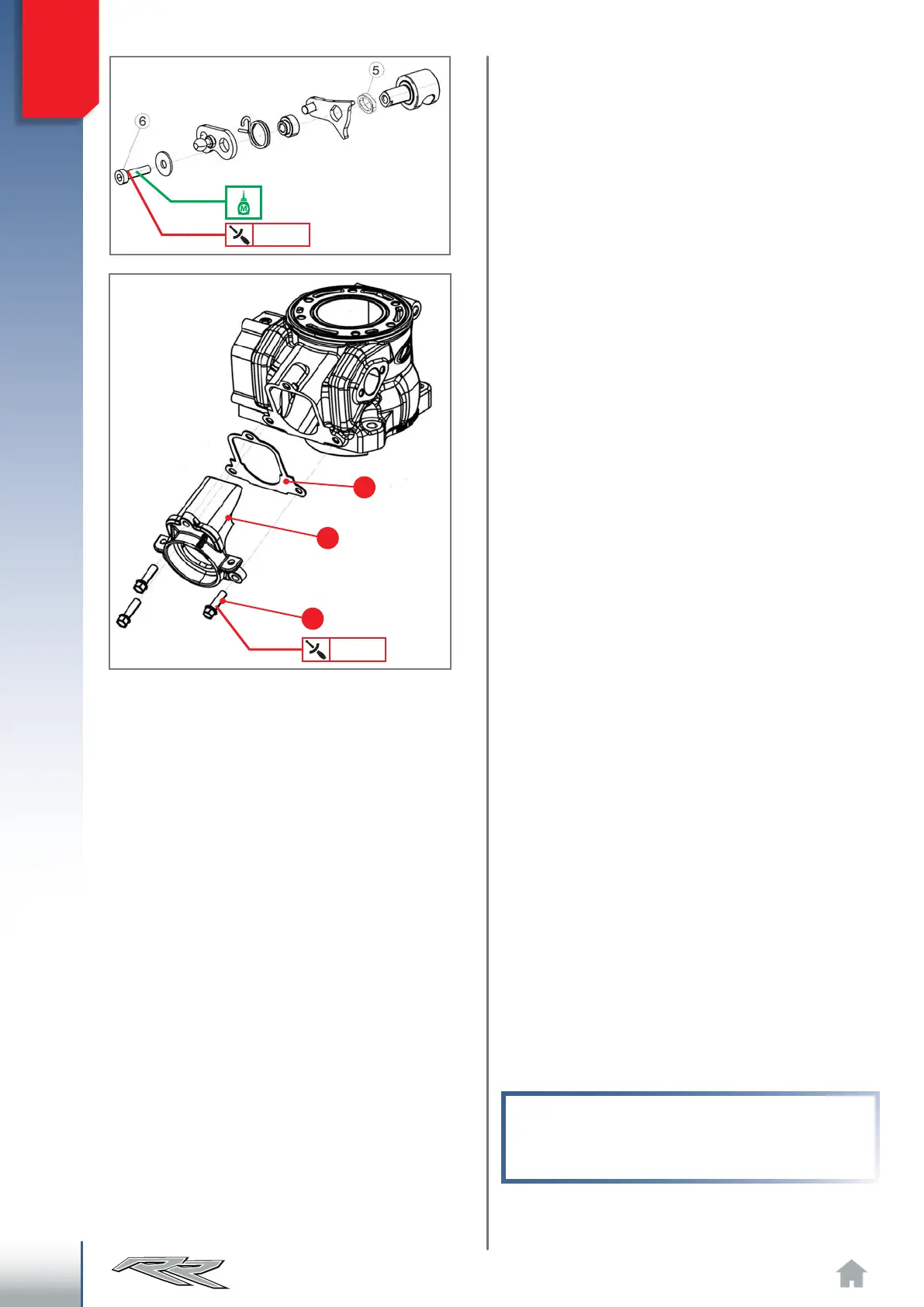

3

98

10Nm

6

7

8

10Nm

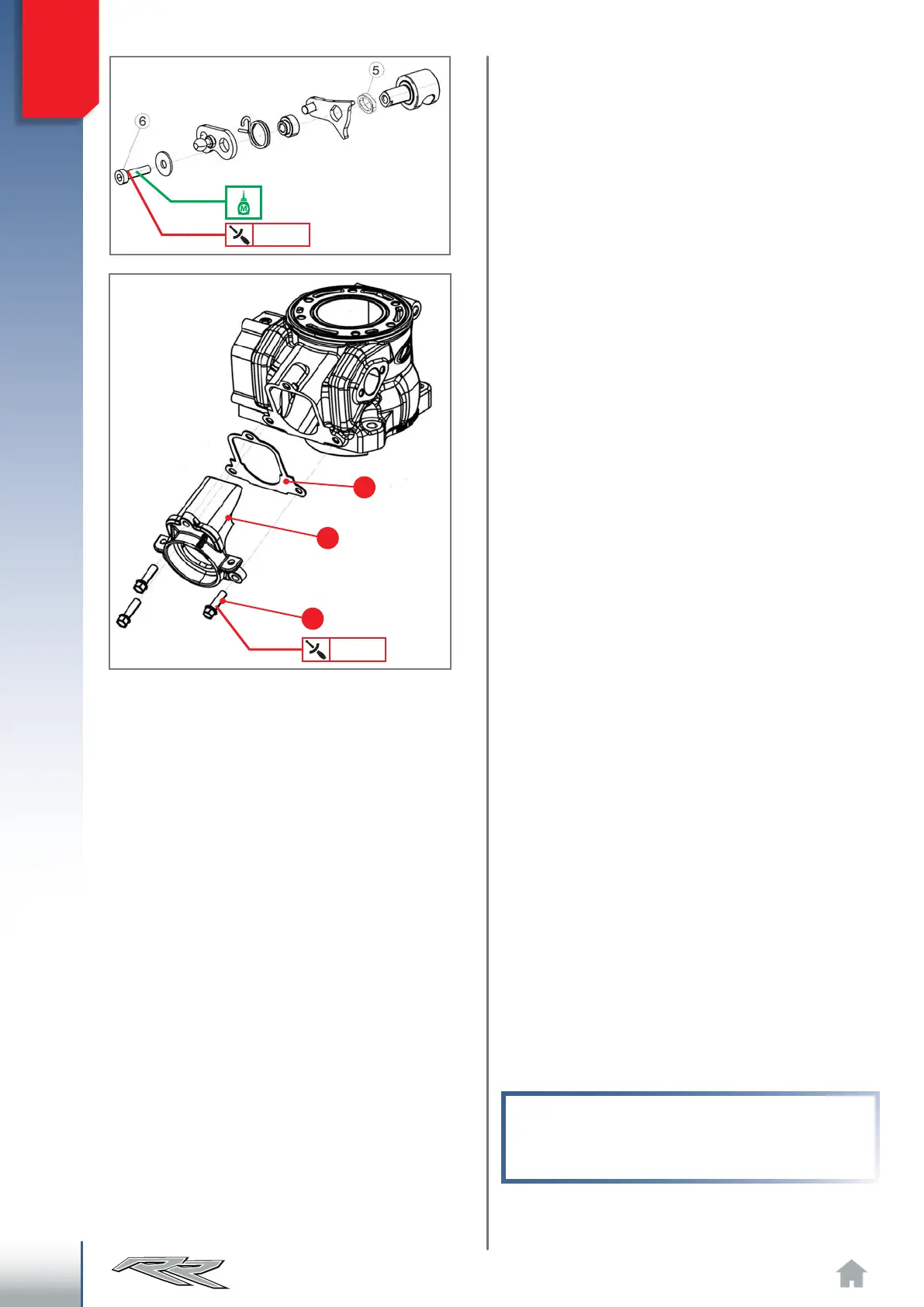

ENGINE CHECKS AND ASSEMBLY

3.12.6 PISTON, PIN BOLT, ELASTIC

BANDS AND CYLINDER AS-

SEMBLY

Insert a circlip for retaining the pin bolt in one of

the seats on the piston's side, placing the circlip's

open part either upwards or downwards.

Apply the roller cage in the connecting rod's foot,

and lubricate it.

Oil pin bolt and seat in piston. Insert the pin bolt

in the piston from the side opposite where the

circlip was inserted, leaving enough space to

allow the connecting rod to mate with the piston.

Place the piston so that the arrow stamped on the

crown is facing the front of the engine (exhaust

opening). Couple the piston to the connecting

rod by fully pushing the pin bolt until flush with

the previously inserted circlip. It may be helpful

to use an aluminium cylinder (or similar tool)

during this phase.

WARNING!

Place a clean cloth between the piston and the

crankcase to keep foreign objects from falling

inside the base.

Apply spacer 5 to the control side.

Then apply all other parts.

Screw 6 must be covered with medium strength

threadlocker and fastened to the indicated torque.

Try moving the assembly and check the entire

mechanism slides perfectly, once assembly is

completed.

Loading...

Loading...