3

68

14

3

B

A

ENGINE CHECKS AND ASSEMBLY

3.7.2 Assembly of kickstarter

device - Optional

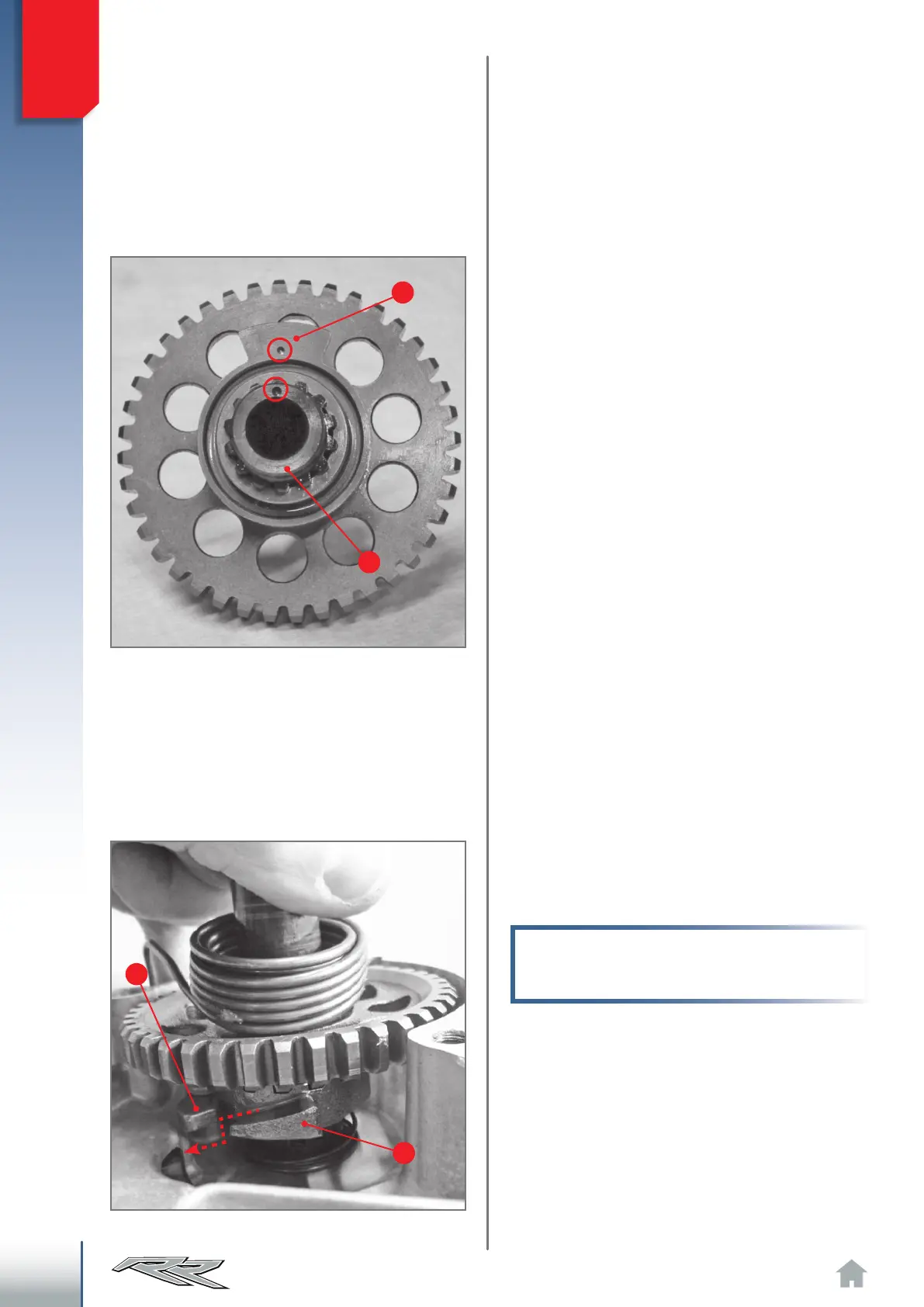

Insert the complete kickstart shaft in its housing,

keeping the thin-striped facing outwards and mak-

ing sure that the ramp A on the kickstart sleeve

is positioned below the ramp B bolted onto the

right crankcase half (external side).

Note: to fit the ramp A refer to para. “3.1.1

Specific applications of the right hand crank

case”.

Remove the kickstart spacer 9, expand the circlip

10, allowing for the removal of washer 11, of kick-

start gear 2 together with roller bearing 12 and

washer 11. This frees the kickstart shaft 3 from all

other parts.

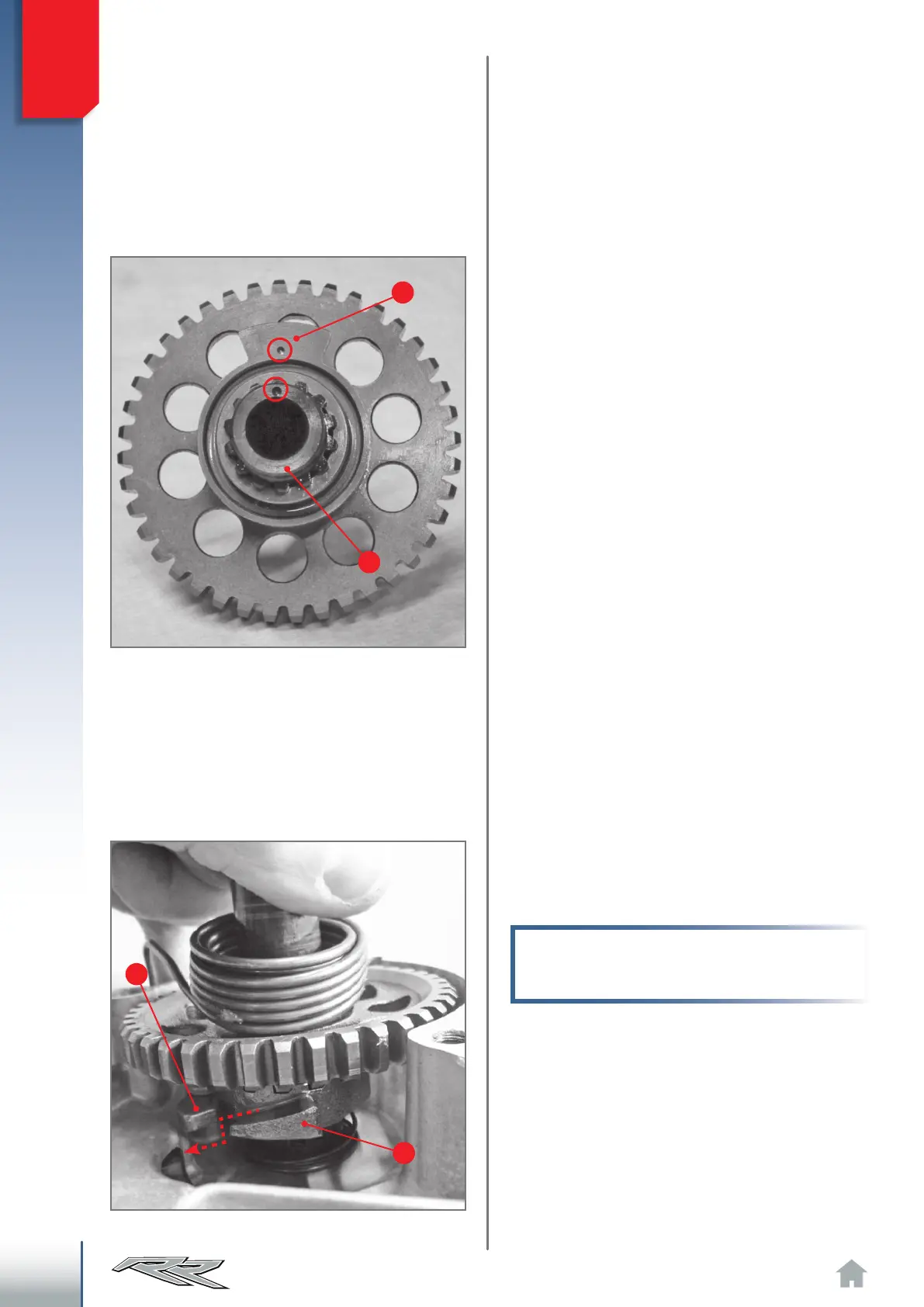

Make sure that the side of the kickstart gear teeth

2 has no signs of meshing or notable superficial

wear. Make sure that the front teeth (sleeve side

14) are not chipped. Replace any part that shows

the aforementioned defects.

Make sure that the front teeth of the sleeve 14

are not chipped and that the spring 16 is capable

of exerting enough pressure on the sleeve 14 so

that this can pull the wheel 2.

Also check to make sure that no washers have

any abnormal or excessive wear. If so, replace

them. Make sure that the spring 8 has no cracks

or abnormal deformation. Replace if it is not able

to bring the external kickstart lever back to the

rest position.

For reassembly, follow the above disassembly

procedure in reverse order.

Pay attention to the correct positioning of the

sleeve 14 in respect to the shaft 3. The front of

the shaft has a reference sign, just as the sleeve

14 does: the two references must match.

Positioning of sleeve on small shaft.

Positioning of sleeve A below lever B.

Loading...

Loading...