21

For replacement of an existing sensor perform

steps 2a and 3a then proceed to step 4a or 4b.

2a. From the outer surface of the sensor cover, use a

flat blade screwdriver to gently push out the metal

screen (if present), gasket & filter ring assembly.

Discard old gasket, filter ring assembly & metal

screen. The metal screen is not to be reused and

its absence will not affect sensor performance.

3a. Remove any remaining traces of adhesive from the

recessed hole in the sensor cover.

For new sensor installation perform steps 2b and 3b

then proceed to step 4a or 4b.

2b. From the outer surface of the sensor cover, push

out yellow dust cap with a blunt tool.

3b. Remove sensor blank from the sensor

compartment.

For Sensors O

2

, LEL, CO, CO Plus, CO-H, H

2

S, NO,

DUO-TOX perform step 4a then proceed to step 5.

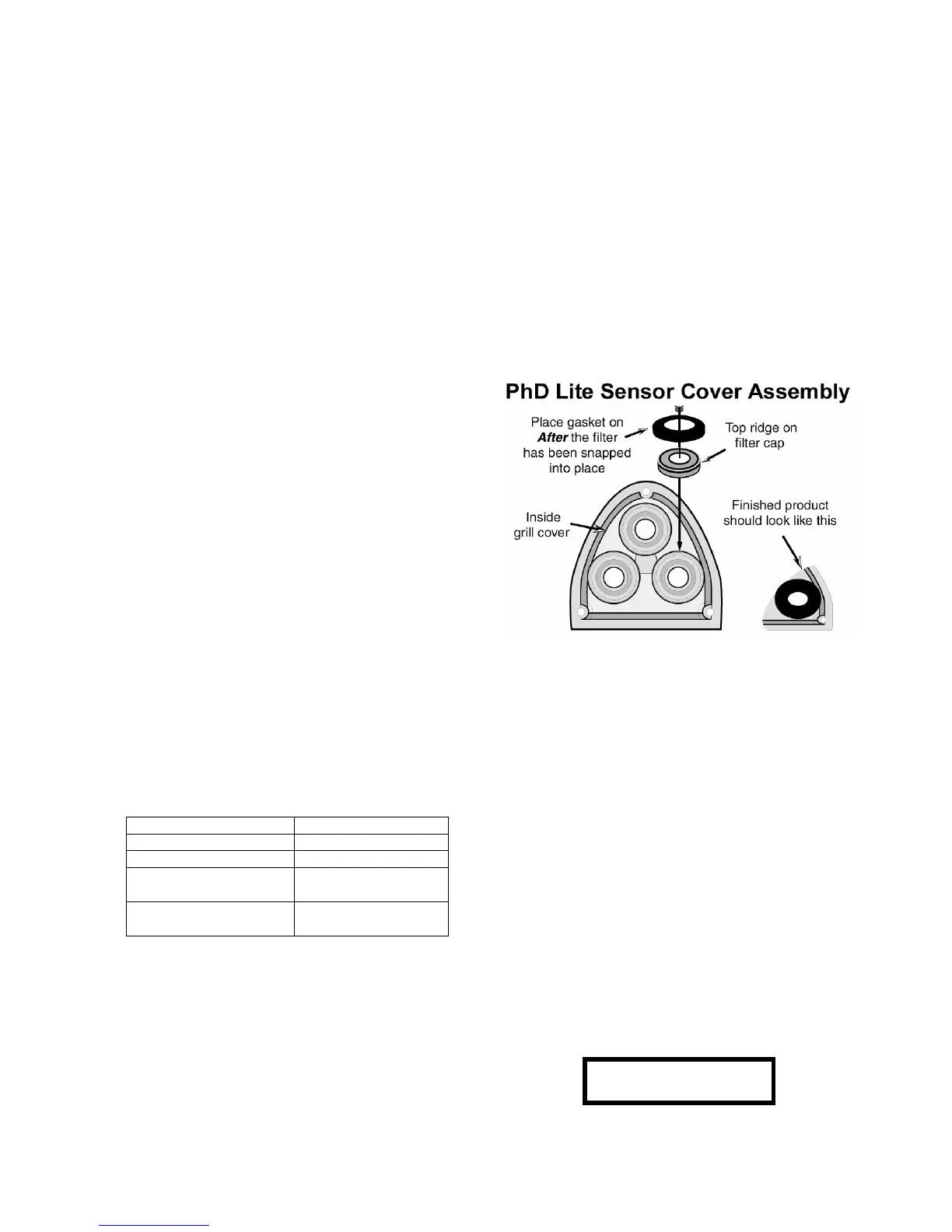

4a. Firmly press the new filter ring assembly into the

recessed hole in the sensor cover with ridge side

up.

For Reactive Gas Sensors: SO

2

, NO

2

, PH

3

, HCN, Cl

2

,

ClO

2

perform step 4b then proceed to step 5.

4b. Firmly press the new teflon spacer into the

recessed hole in the sensor cover. For optimal

sensor response, no external filter element is used

with these sensors.

CAUTION: Since the reactive gas sensor face

is openly exposed to the ambient environment,

extra care should be taken to prevent water or any

other liquids from coming into contact and

remaining on the sensor face.

5. Peel the backing paper from the new rubber gasket

and center it over the newly mounted filter ring

assembly with the adhesive side down.

6. Remount sensor cover and secure with three

philips screws. DO NOT overtighten.

7. Install functional battery pack or batteries in the

detector.

8. New sensors must be allowed a stabilizing time –

with detector powered off and with functional

batteries or battery pack installed, according to the

following schedule.

Sensor Stabilization Period

Oxygen (54-25-90) 1 hour

LEL (54-25-80A) 5 minutes

All Toxic sensors except

those shown below

15 minutes

54-25-04 NH

3

Sensor

54-25-06 NO Sensor

24 hours

9. The PhD Lite will automatically recognize the

changes that have been made upon turn on and

display the “Warning Needs Cal” message.

10. Calibrate the PhD Lite with calibration gas

appropriate for the new sensor before the

instrument is put back into service.

11. If newly installed sensor(s) do not appear during

power-up, or if the message "not supported"

appears, contact Biosystems Instrument Service

Dept. for further guidance.

PhD Lite programming includes safeguards to recognize

maladjusted sensors. If the settings on the new sensor

are significantly different from those of the sensor that is

being replaced, a message indicating that the sensor is

reading “Too Low” or “Too High” for Auto-Calibration

may follow the first attempt at one-button calibration.

Note: The first fresh air calibration adjustment after

installation of a new sensor should be done using

the “manual” calibration procedure as discussed in

section 4.5 of this manual

Once the new sensor has been fresh-air calibrated

using the “manual” calibration procedure, subsequent

fresh air and span calibrations can be made by using

the MODE button and One-Button Auto-Calibration

procedures.

2.6.4 Missing sensor

The PhD Lite is able to recognize when a sensor is

removed or becomes disconnected while the instrument

is in normal operation. If a sensor becomes

disconnected while the instrument is turned on, the PhD

Lite will trigger a missing sensor alarm, the

corresponding channel of the display will show an “X” in

place of the normal sensor readings and the audible and

visible alarms will be activated.

2.6.5 “Sensor not found”

If the PhD Lite is suddenly unable to read the EEPROM

of a smart sensor currently installed the corresponding

sensor channel will show an “X” and the audible and

visible alarms for the affected sensor channel will be

activated.

If a smart sensor is removed while the instrument is

turned off without being replaced with another sensor, a

message will be displayed during the start-up sequence

indicating that the sensor is missing. Pressing the

MODE button acknowledges the condition, and allows

the use of the instrument for those sensors that have

been successfully detected.

NO TOX1 SENSOR

MODE=Acknowledge

Loading...

Loading...