Mechanical Dock Leveler – M and FMC Group 03, Section 01, Page 3

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

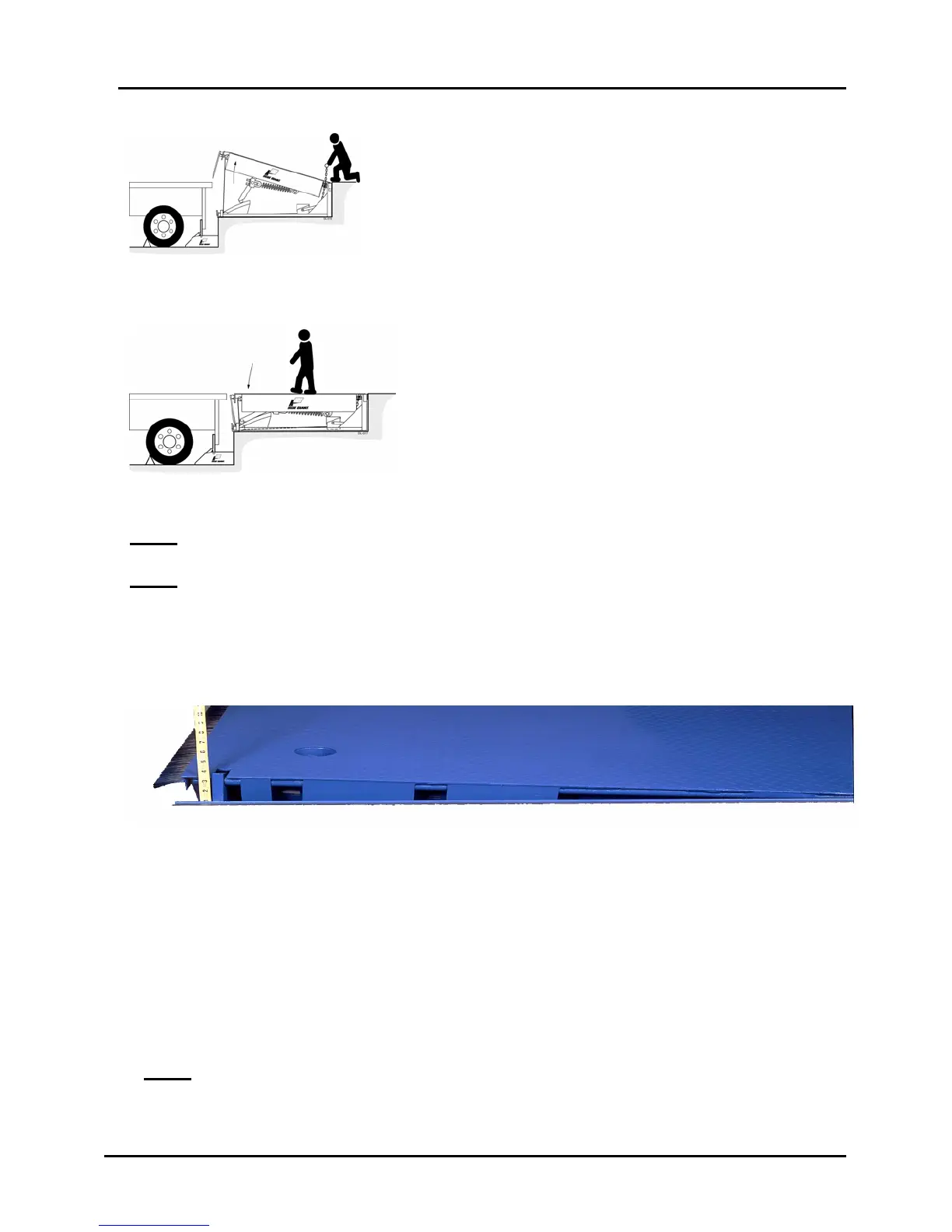

RETURN TO STORED POSITION

To return the deck to stored position after

the vehicle is Loaded or Unloaded and is

still at the dock, pull up and hold the

release chain "only long enough" for the

lip to clear the truck bed and fold in fully.

WALK THE DECK DOWN

Walk the deck down to the stored

position, ensuring that the lip is located

inside the lip keepers.

Note: Releasing the operating ring at any time will stop the upward travel of the deck.

Note: Should the truck depart before the dock leveler is returned to stored position, the

lip will automatically swing down to a hanging position. If the truck being serviced was

lower than the dock and the lip is not located inside the keepers, raise the deck

approximately 12” above dock height and then walk it down to stored position.

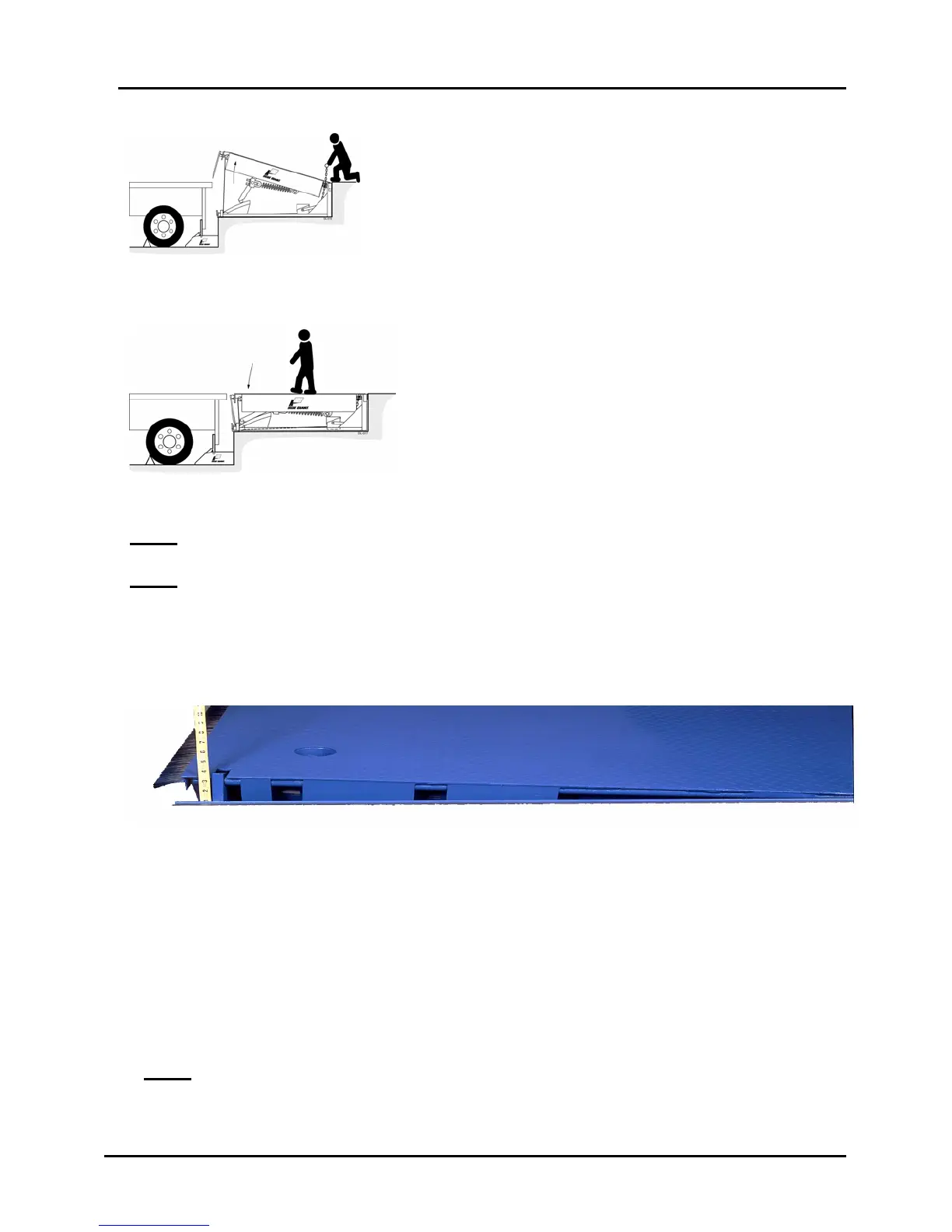

DIAGONAL FLOAT ABILITY

Irregularities in left to right corner height of the truck floor are sometimes caused by

uneven paving or lop sided loads. The design of the Blue Giant Dock Leveler

incorporates the use of "Tilt Bars and Pockets". These are floating hinge and mount

points located at the rear of the deck that allow the deck to float diagonally and

compensate for irregularities in left to right corner height of the truck floor. This

extends deck life by preventing deck twisting and also prevents lift truck tire damage

by allowing full width lip contact.

Note: In use, the Dock Leveler deck adjusts itself to tilted load beds and raises and

lowers automatically with movements of the load bed. (It is normal for a rear corner

to raise above floor level during use to compensate for a tilted truck bed).

Loading...

Loading...