Mechanical Dock Leveler – M and FMC Group 08, Section 07, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

FLOAT SPRING and CABLE ROLLER REPLACEMENT

1) Raise dock leveler and position

maintenance strut and traffic barriers as

required for safety.

2)

The hold down cable will now be

handled. Wire wound cables become

frayed with use and must be handled

with care. Use leather gloves or similar

protection. Enter pit area and remove

hold down box cover, counterweight and

lock roller.

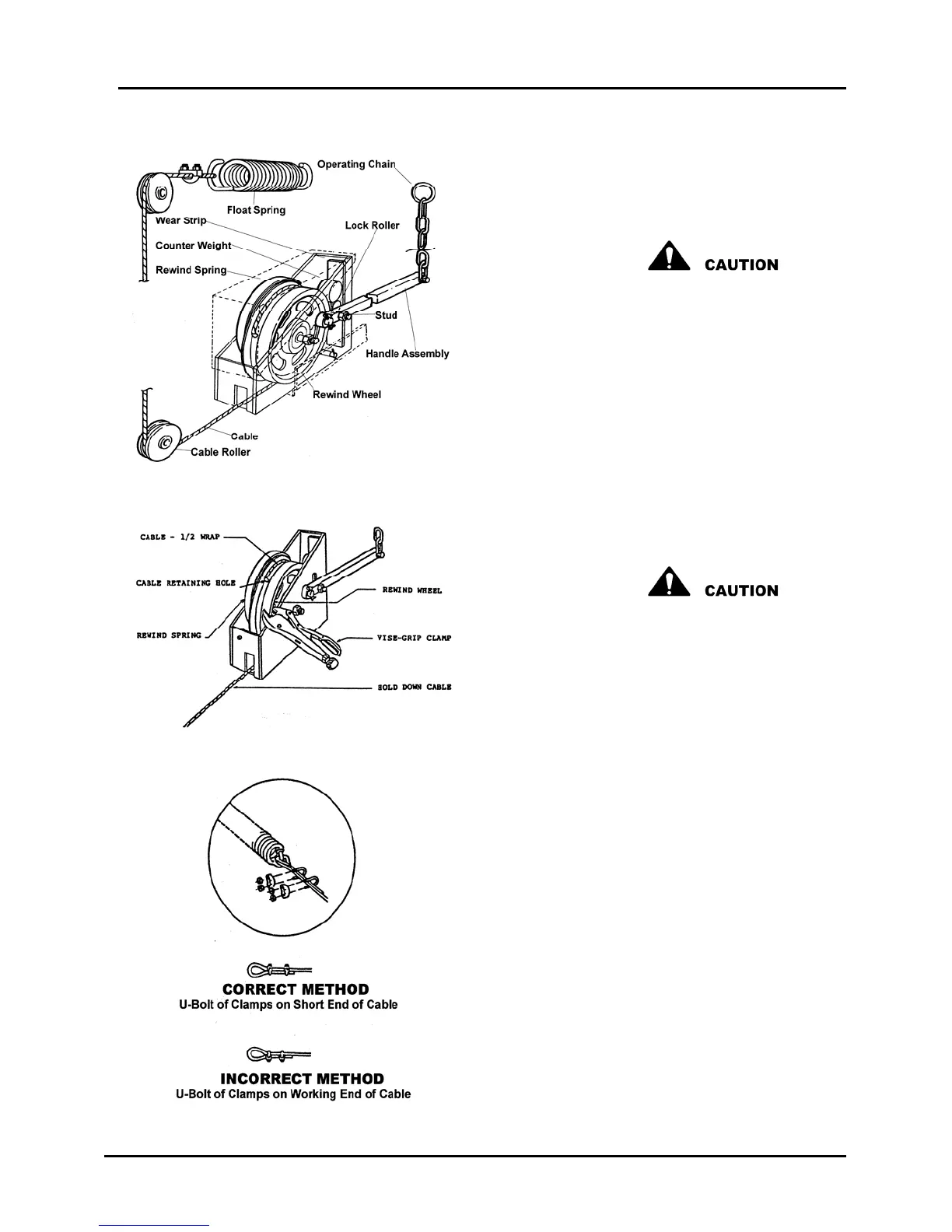

3) See Figure 28 for illustration of hold

down box system, float spring and cable

rollers.

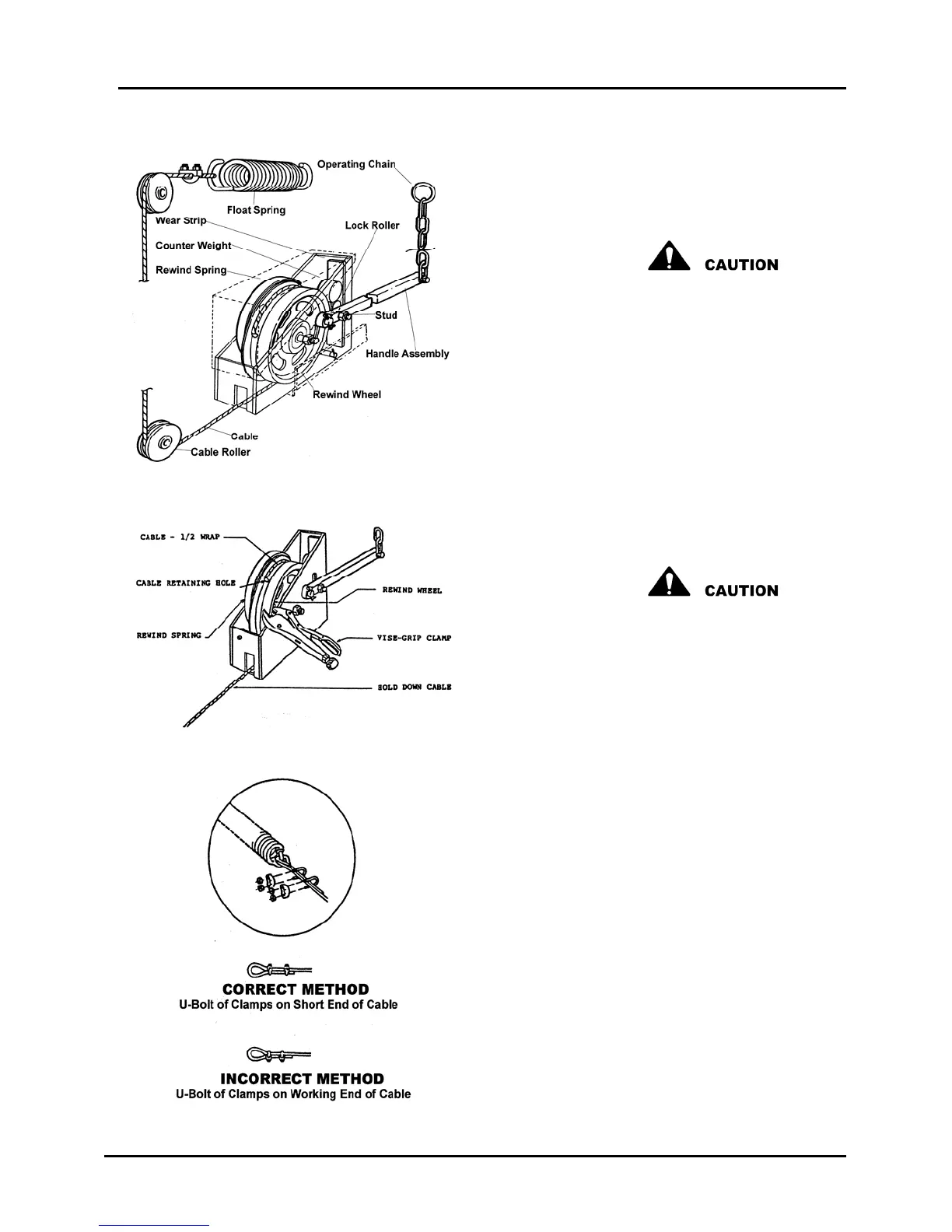

4)

The rewind spring is applying tension to

wind the hold down cable into the hold

down box, grip the cable firmly and

proceed carefully. Pull the cable out of

the box slowly, hand over hand, until all

cable is unwound from the rewind wheel

or the rewind spring is fully tensioned

and will allow no further rotation of the

rewind wheel. Lock the rewind wheel in

this position with vice-grips or other

suitable clamping device. The rewind

spring is now under full tension, work

with appropriate caution. Remove and

replace float spring and / or cable rollers

as required. See Figure 29.

5) Feed the loose cable end through lower

and upper cable rollers and through the

front eye of the float spring, Loop cable

back over thimble and install the cable

clamp in its original position. Tighten

clamp securely. See Figure 30.

Figure 28

Figure 29

Figure 30

Loading...

Loading...