Mechanical Dock Leveler – M and FMC Group 04, Section 01, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

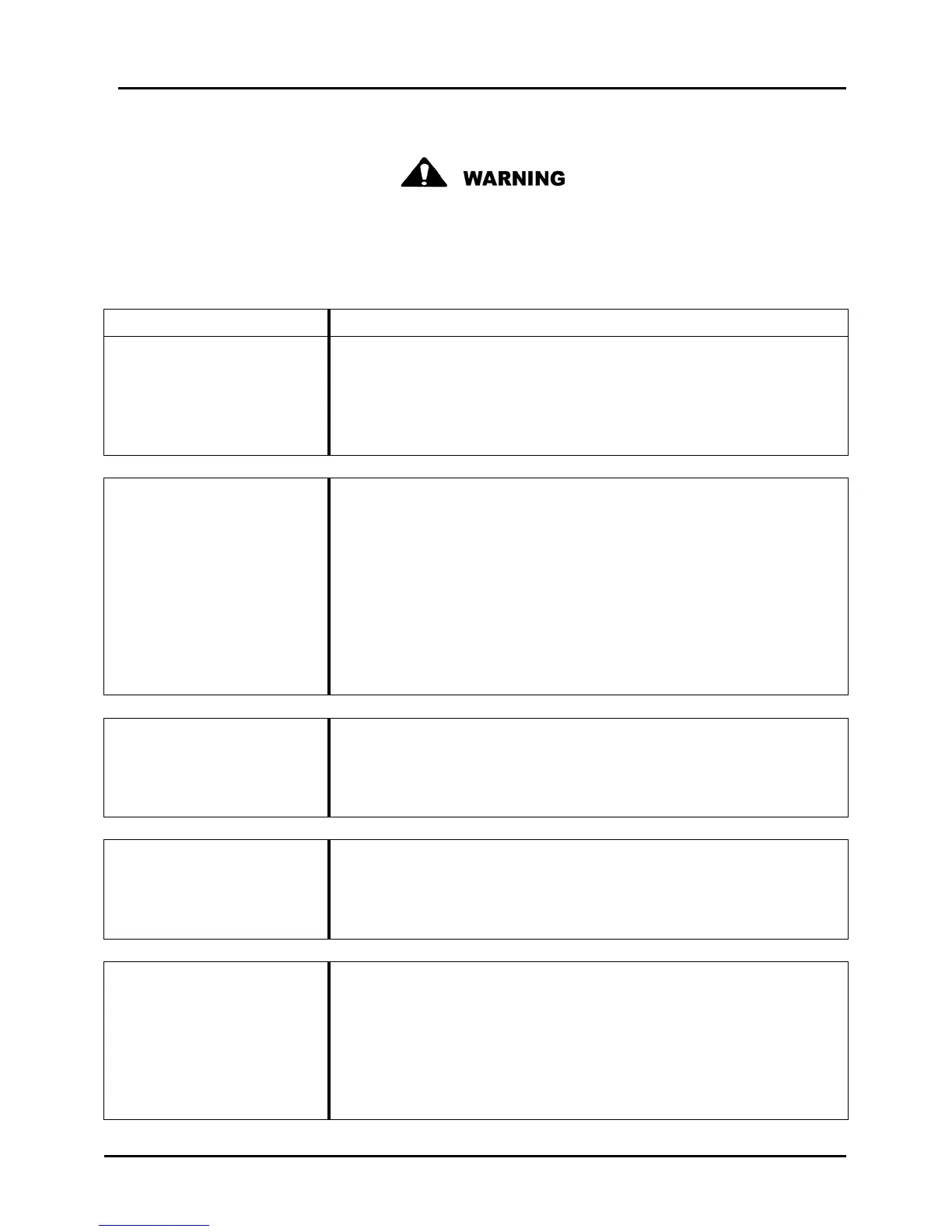

TROUBLESHOOTING

DO NOT attempt to make repairs or adjustments yourself, only

Trained and Authorized Personnel should perform repairs or

adjustments.

Contact your local Blue Giant Distributor for assistance

PROBLEM PROBABLE CAUSE

DECK DOES NOT RAISE

1. Hold down mechanism not releasing.

- Release chain, handle or locking roller jammed or broken.

2. Foreign material lodged between side of deck and pit wall.

3. Damaged or missing bumpers allowing truck to contact and

hold lip

4. Lifting arm cam roller knocked off cam and jammed.

DECK DOES NOT RAISE

FAST ENOUGH TO

SWING LIP UP TO

FULLY EXTENDED

POSITION

1. Foreign material lodged in lip hinge, preventing full rotation.

2. Deck drag on side of pit, slowing deck.

- Foreign material lodged between side of deck and pit wall.

- Safety skirt damaged and dragging on pit wall

(when used).

- Out of square pit causing deck to drag on side of pit.

3. Lifting arm cam roller has groove worn in by cam.

4. Lack of lubrication on lip hinge spools.

5. Lifting springs require adjustment.

- Assure all other possible causes have been

eliminated before changing spring adjustment.

LIP DOES NOT LOCK

AFTER REACHING THE

FULLY EXTENDED

POSITION

1. Lip lock not engaging.

- Broken or stretched lip-lock spring.

- Lip lock seized - not rotating into lock position.

2. Lip actuator bent or broken.

3. Foreign material lodged in lip lock mechanism.

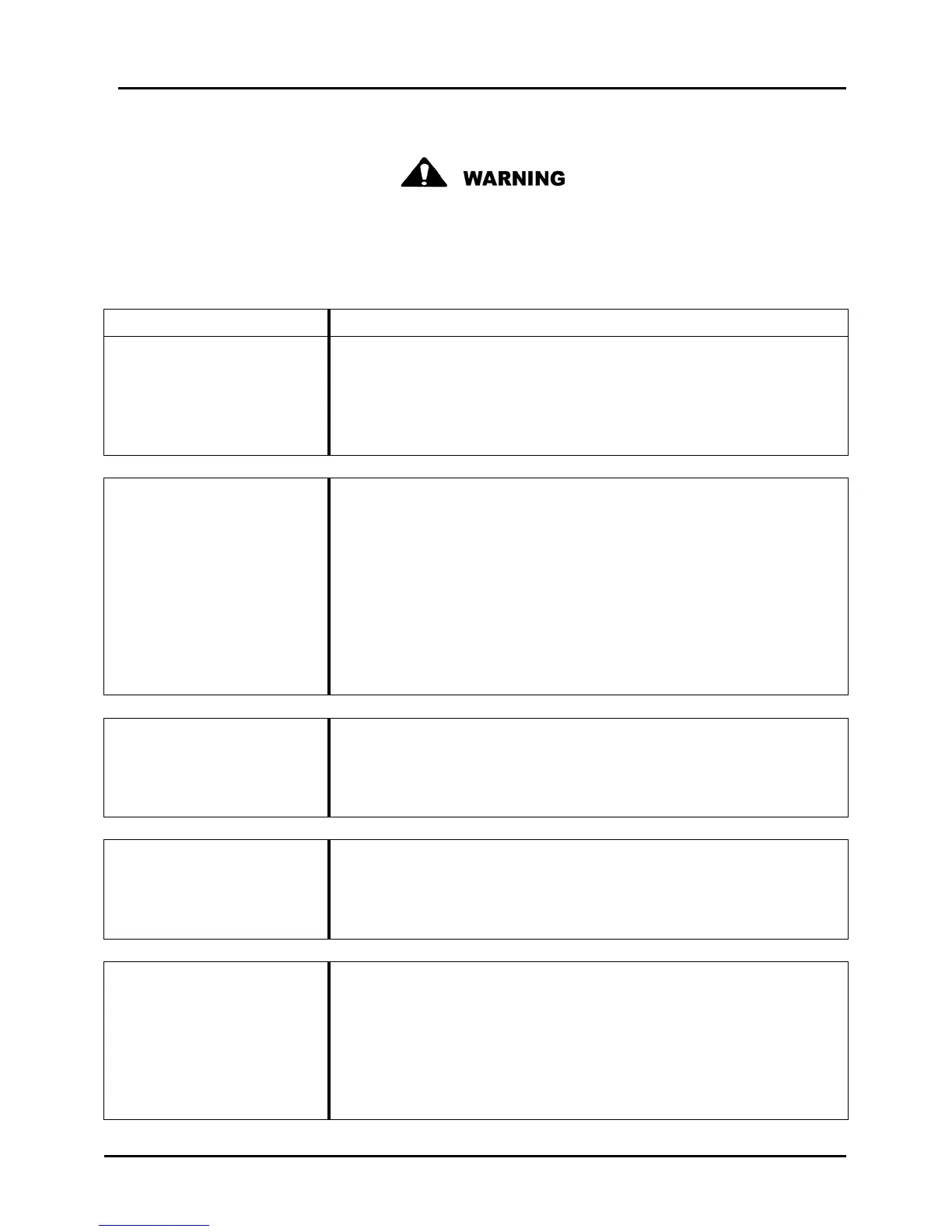

DECK WILL NOT

“WALK” DOWN

1. Foreign material in pit, blocking mechanism.

2. Side safety skirts badly damaged and jammed against pit

wall (when used).

3. Lifting Arm cam roller knocked off cam, causing lifting arm

to jam against cam.

DECK IS VERY HARD TO

“WALK” DOWN

1. Weather seals, skirts or deck dragging on pit wall.

2. Foreign material in pit.

3. Cam roller grooved badly by cam wear.

4. Cam roller bearing seized.

5. Lack of lubrication.

6. Lift springs adjusted improperly.

- tension has been mistakenly increased to overcome

another problem.

Loading...

Loading...