Mechanical Dock Leveler – M and FMC Group 08, Section 15, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

LIP CROWN MODIFICATION – Special Application

Increasing Lip Crown

NOTE: The following instructions and

information are to be used only after a

thorough inspection has been

performed to verify that damage or

excessive wear are not evident in any

of the associated components.

Do not change the lip crown to

compensate for damage or wear.

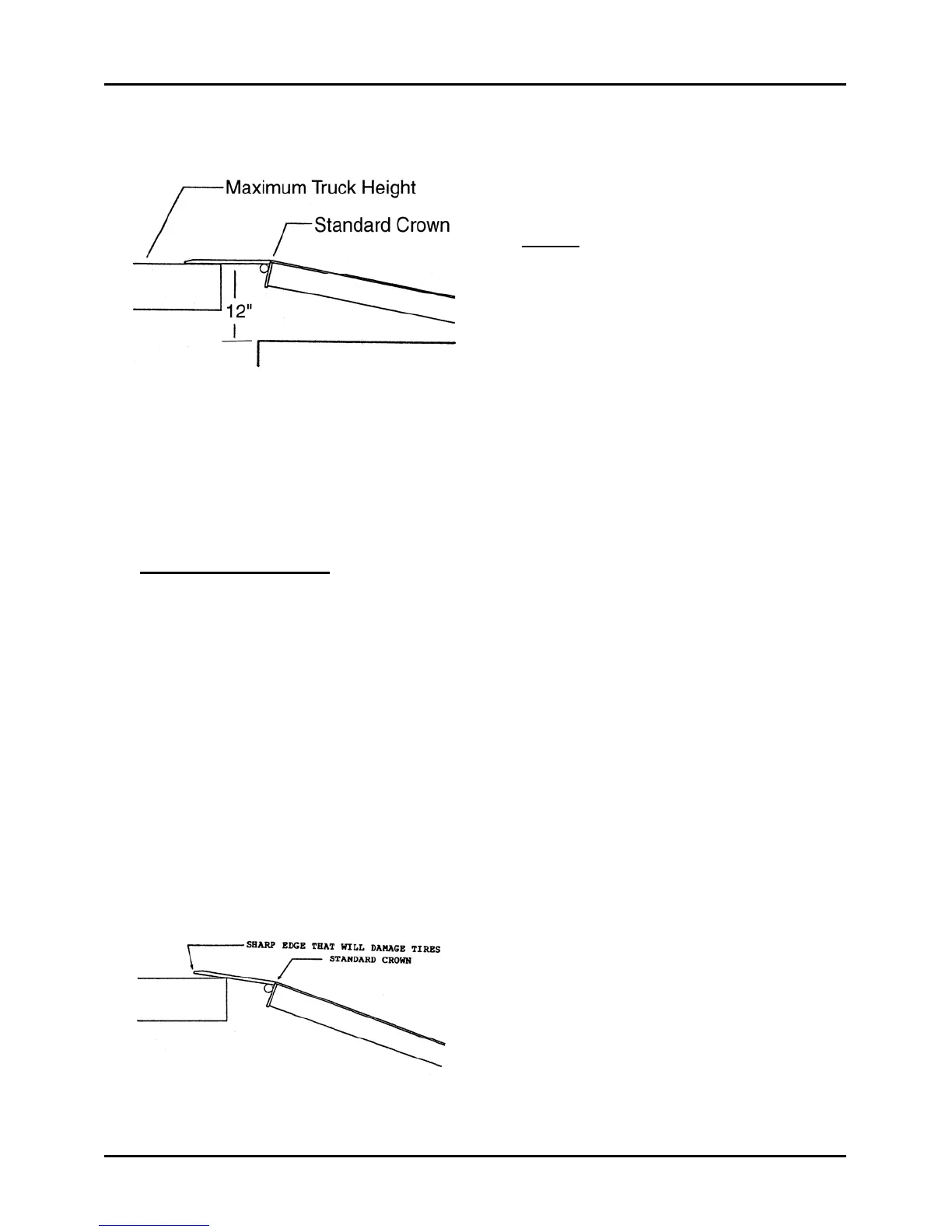

Figure 89

Changing the lip crown will affect the operating range and efficiency of the dock

lever. Investigate the application thoroughly when considering a crown change, to

assure the change will not adversely affect the overall efficiency of the specific

application.

Increasing Lip Crown: This modification is unusual and is most often considered

as a possible solution for the problems experienced when higher than normal

vehicles such as shipping containers must be serviced with a dock leveler that is not

of sufficient overall length. Eg: A dock leveler that is 144" overall length is

recommended for use when the height differential between truck bed and dock is 12"

and a low lift pallet truck will be used for unloading/loading. Increasing the amount

of lip crown will allow the tip of the lip to maintain contact with the high vehicle, but it

may also create a hang-up point for limited under clearance material handling

equipment such as pallet trucks. The degree of incline of the dock leveler deck will

also increase slightly, requiring more overhead clearance for high loads and lift truck

masts. Replacing the complete dock leveler is often the only satisfactory method of

solving this problem.

Figure 89, illustrates a standard crown dock leveler positioned on a truck bed that is

at maximum height for the dock leveler length.

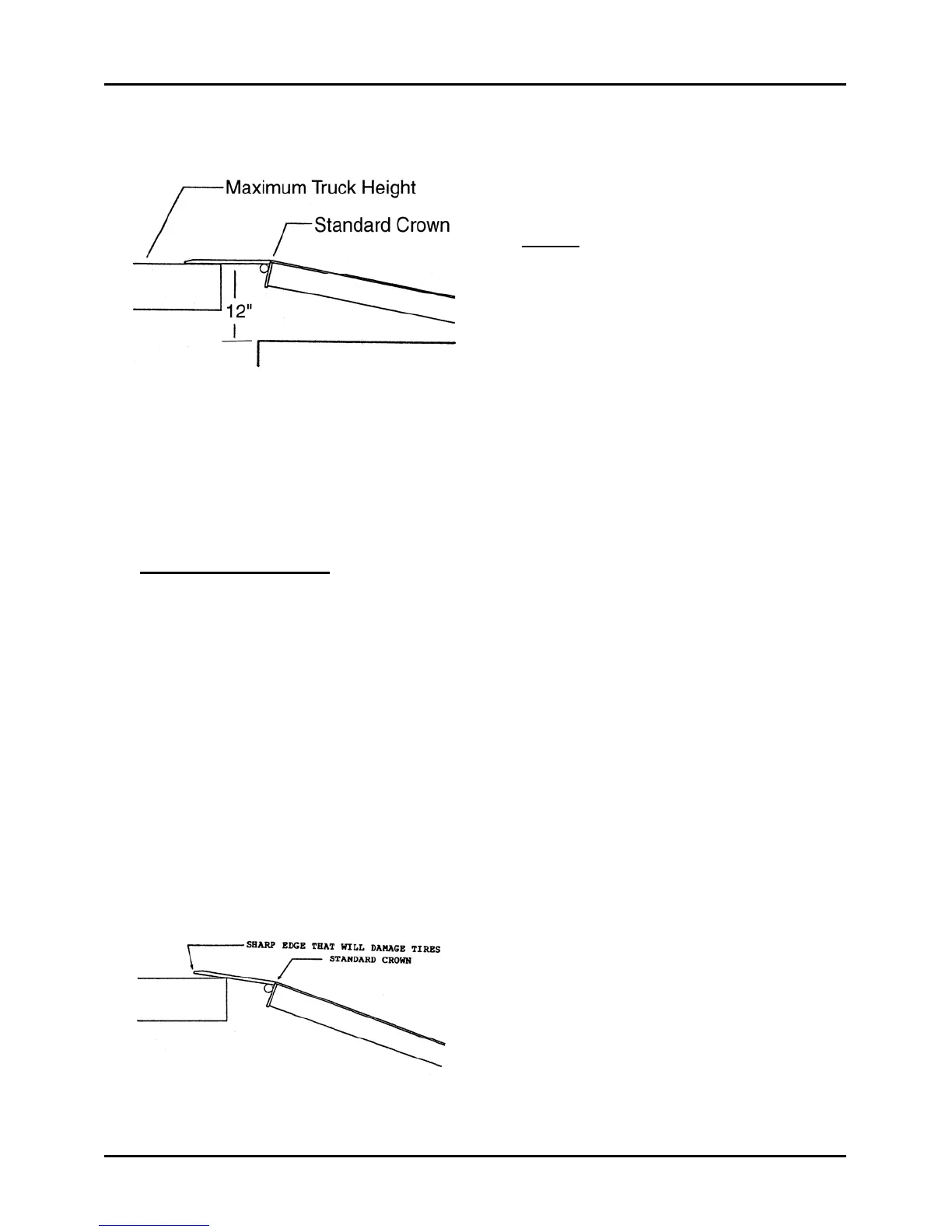

Figure 90, illustrates the same

standard crown dock leveler as shown

in Figure 89, positioned on a truck bed

that is higher than recommended for

the dock leveler length. Note that the

tip of the lip is not in contact with the

truck bed, creating a sharp edge that

will damage the tires etc. of the

material handling truck exiting the

vehicle.

Figure 90

Loading...

Loading...