Mechanical Dock Leveler – M and FMC Group 08, Section 13, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

LIP REPLACEMENT

NOTE: This section is to be used only for

the purpose of replacing or repairing

damaged or worn-out lip and hinge

components using same size and

capacity parts. If the lip is to be changed

for other reasons, Eg: longer lip, refer to

Group 08, Section 16, Page 1.

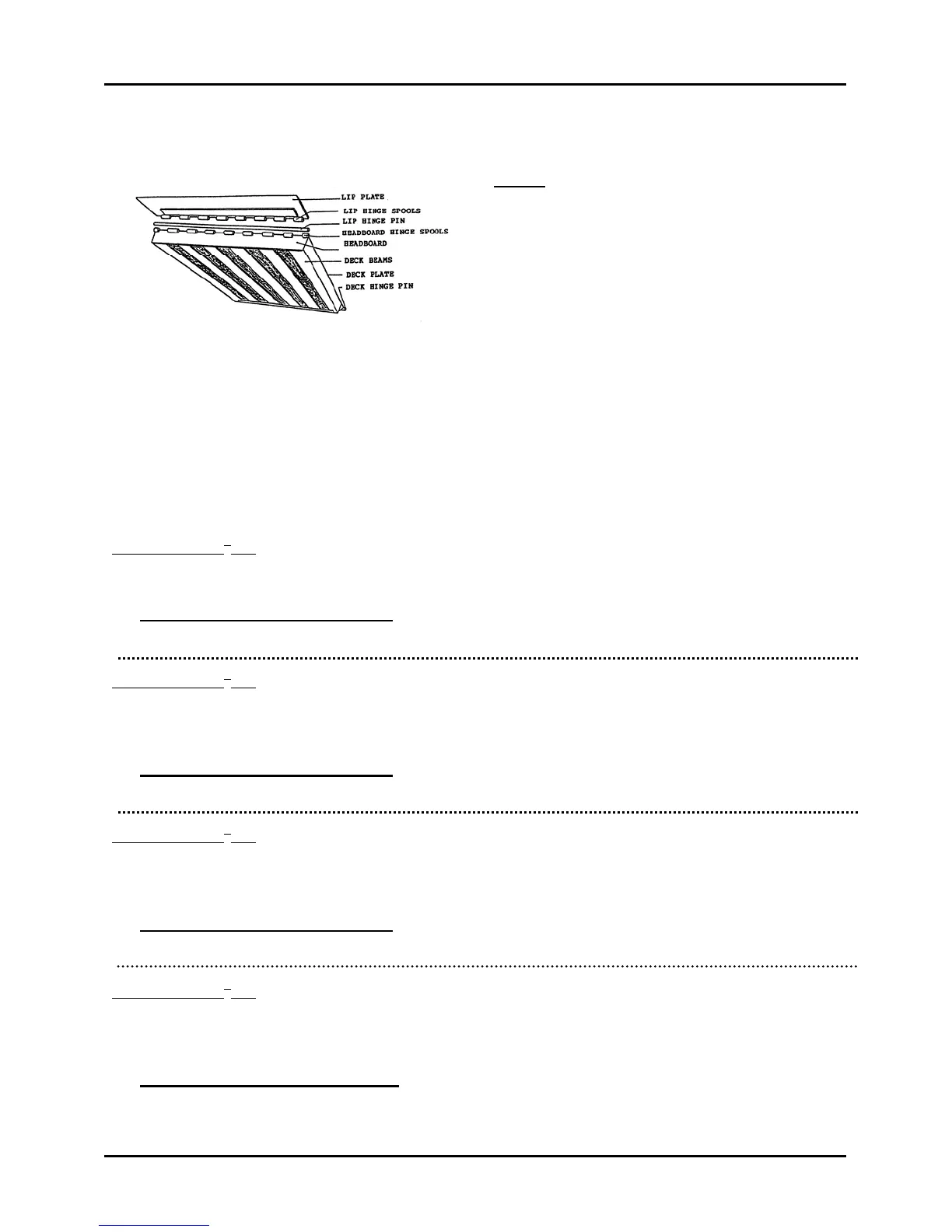

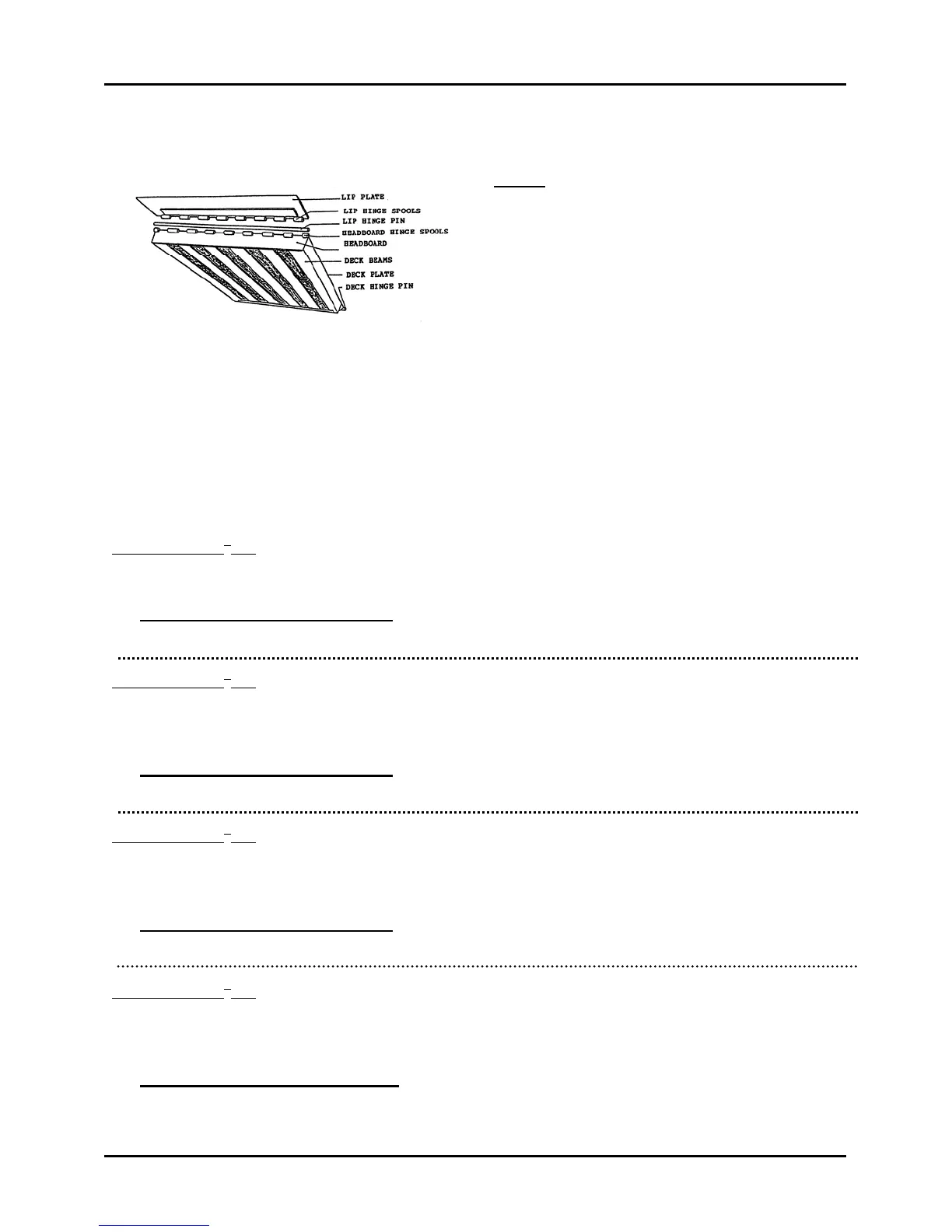

Figure 55

The dock leveler lip hinge-pin, Figure 55, is a full length, one-piece shaft and must be

completely removed for lip replacement. When a door frame or building wall will interfere

with the removal of the hinge pin, the deck must be placed in a position that will allow pin

removal. Inspect the specific site and choose the appropriate method of removal, listed

below, that will best suit the conditions encountered and the equipment available.

METHOD N

o

. 1 – No Interference to Pin Removal

SUPPORT LIP and REMOVE HINGE PIN.

Special Equipment Required: Fork lift truck or other hoisting equipment suitable for

supporting and transporting the lip.

METHOD N

o

. 2 – Door Frame or other Interference to Pin Removal

REMOVE DECK and LIP FROM PIT and TRANSPORT TO A SAFE WORKING

AREA.

Special Equipment Required: Fork lift truck or other hoisting equipment suitable for

supporting and transporting the complete deck and lip assembly.

METHOD N

o

. 3 – Door Frame or other Interference to Pin Removal

HOIST DECK and LIP ASSEMBLY and ROTATE 180

o

ON ITS REAR DECK HINGE

TO PLACE THE DECK UP SIDE DOWN ON THE FLOOR BEHIND THE PIT.

Special Equipment Required: Fork lift truck or other hoisting equipment suitable for

lifting and rotating the deck and lip assembly.

METHOD N

o

. 4 – Door Frame or other Interference to Pin Removal

CUT HEADBOARD HINGE SPOOLS OFF HEADBOARD TO RELEASE LIP and

HINGE.

Special Equipment Required: Fork lift truck or other hoisting equipment suitable for

supporting and transporting the complete lip assembly. Cutting torch and arc welding

equipment.

Loading...

Loading...