Mechanical Dock Leveler – M and FMC Group 08, Section 04, Page 1

Issue Date: 10/01/01, Rev. 0 (Part #038-550E)

HOLD DOWN CABLE REPLACEMENT (Broken Cable)

Note: A broken hold down cable often

indicates long time use or severe working

conditions and may be indicative of the

general condition of the entire hold down

system. When investigation shows this to

be the case, Blue Giant recommends

installing a complete, new hold down box

assembly to assure trouble free use of the

dock leveler. If the decision is made to

replace only the hold down cable, proceed

as follows:

1. Raise dock leveler and position

maintenance strut and traffic barriers

as required for safety. Place a safety

stand between the deck assembly and

the lower frame to assure the deck

cannot lower. Deck must be fully

raised.

2.

Wire wound cables become frayed with

use and must be handled with care.

Use leather gloves or similar

protection.

3. Enter pit area and remove hold down

box cover, counter weight and lock

roller.

Note: At this time, inspect wear strip

and lock roller for wear and use new

components when re-assembling if the

degree of wear indicates they will need

to be replaced within ninety days.

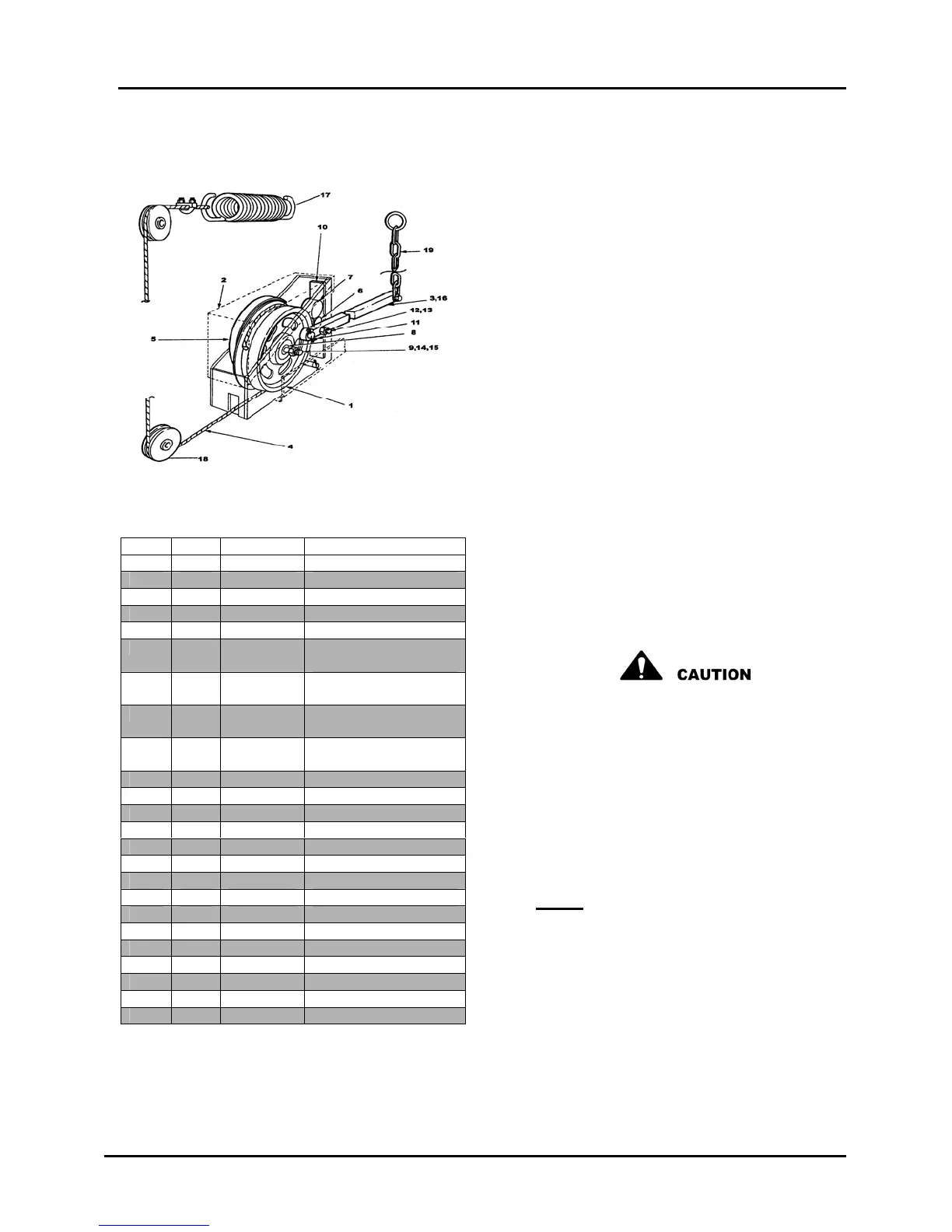

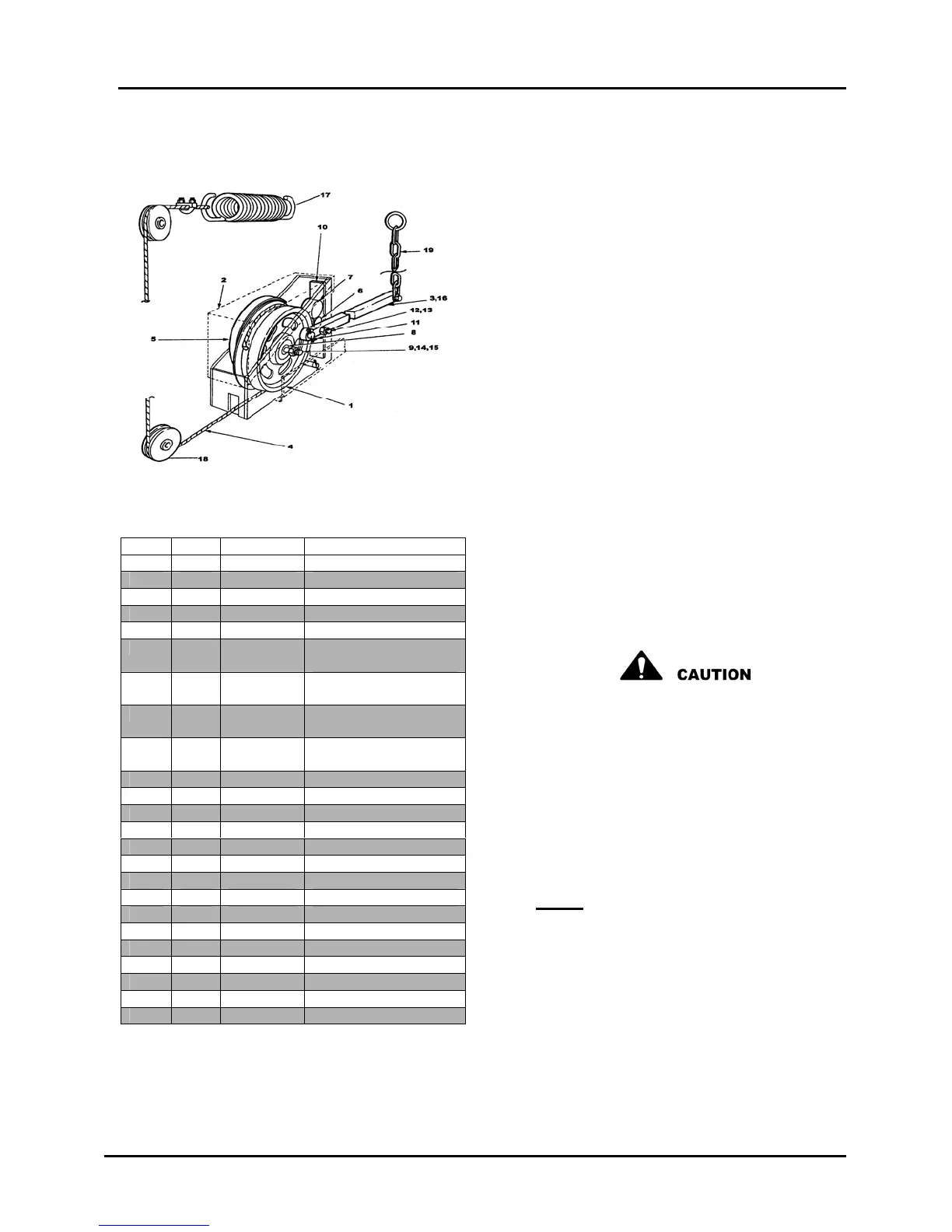

Figure 14

ITEM QTY PART NO

- - 788-037 Complete Assembly

1 1 788-111 Rewind Wheel

2 1 788-034 Cover Assembly

3 1 788-055 Handle Assembly

4 1 788-118 Cable Assembly

– 6’ long dock

4 1 788-118 Cable Assembly

– 8’ long dock

4 1 788-120 Cable Assembly

– 10’ long dock

4 1 788-120 Cable Assembly

– 12’ long dock

5 1 113-143 Coil Spring

6 1 103-167 Lock Washer

7 1 113-085 Counter Weight

8 2 018-500 Bearing

9 1 010-123 Hex Head Bolt

10 1 113-089 Wear Strip

11 1 013-005 Spring Pin

12 1 113-090 Stud

13 1 011-508 Hex Nut

14 1 011-554 Nylock Nut

15 1 113-198 Sleeve

16 1 018-001 Bushing

17 1 793-971 Float Spring Assembly

18 2 793-092 Cable Roller Assembly

19 1 788-187 Pull Chain Assembly

Loading...

Loading...