Group 08, Section 15, Page 2 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

LIP CROWN MODIFICATION

Increasing Lip Crown –

cont’d

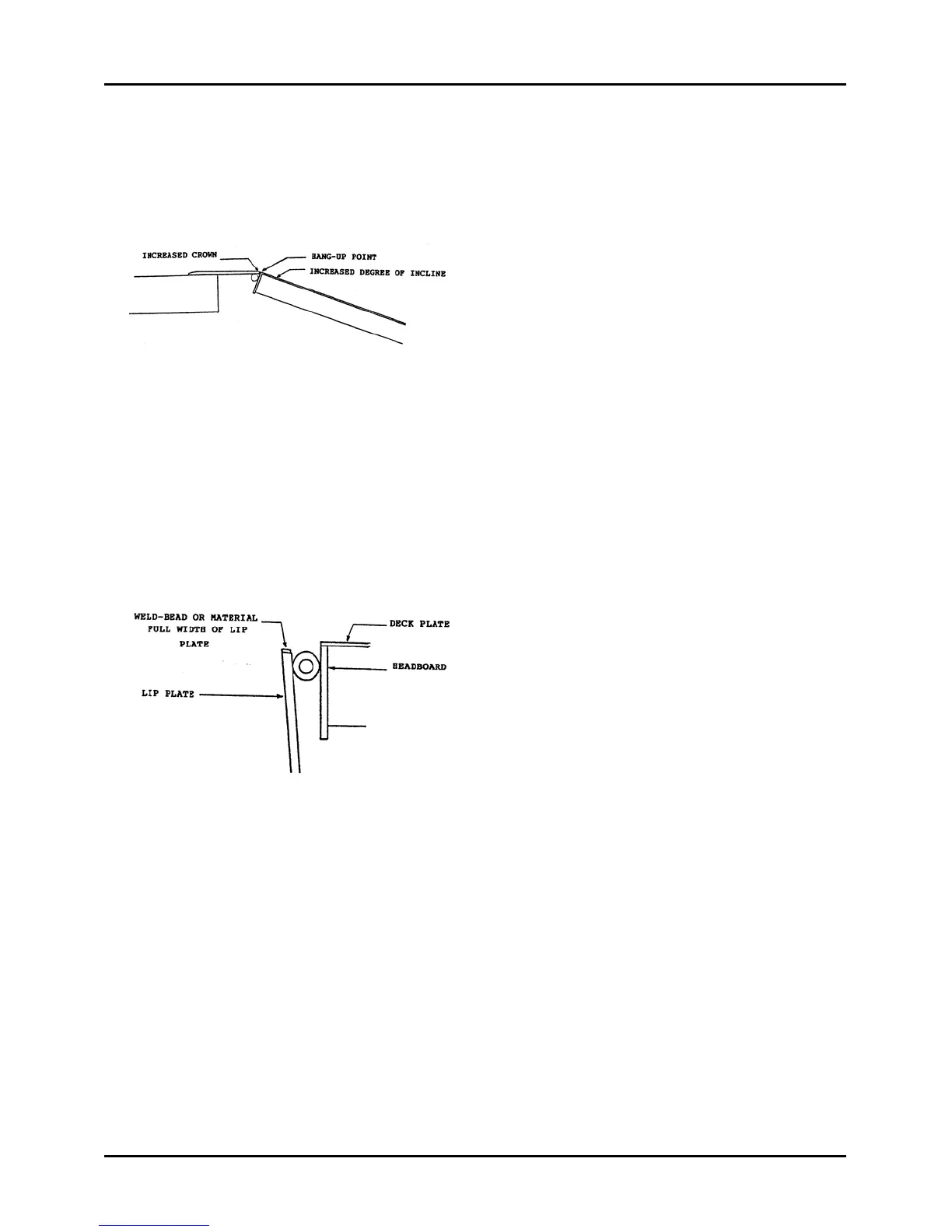

Figure 91, illustrates the same situation

as Figure 90 with the lip modified for

additional crown. Note that the tip of

the lip is now making contact with the

truck bed but that a hang-up point has

been created.

TO INCREASE LIP CROWN -

Proceed As Follows:

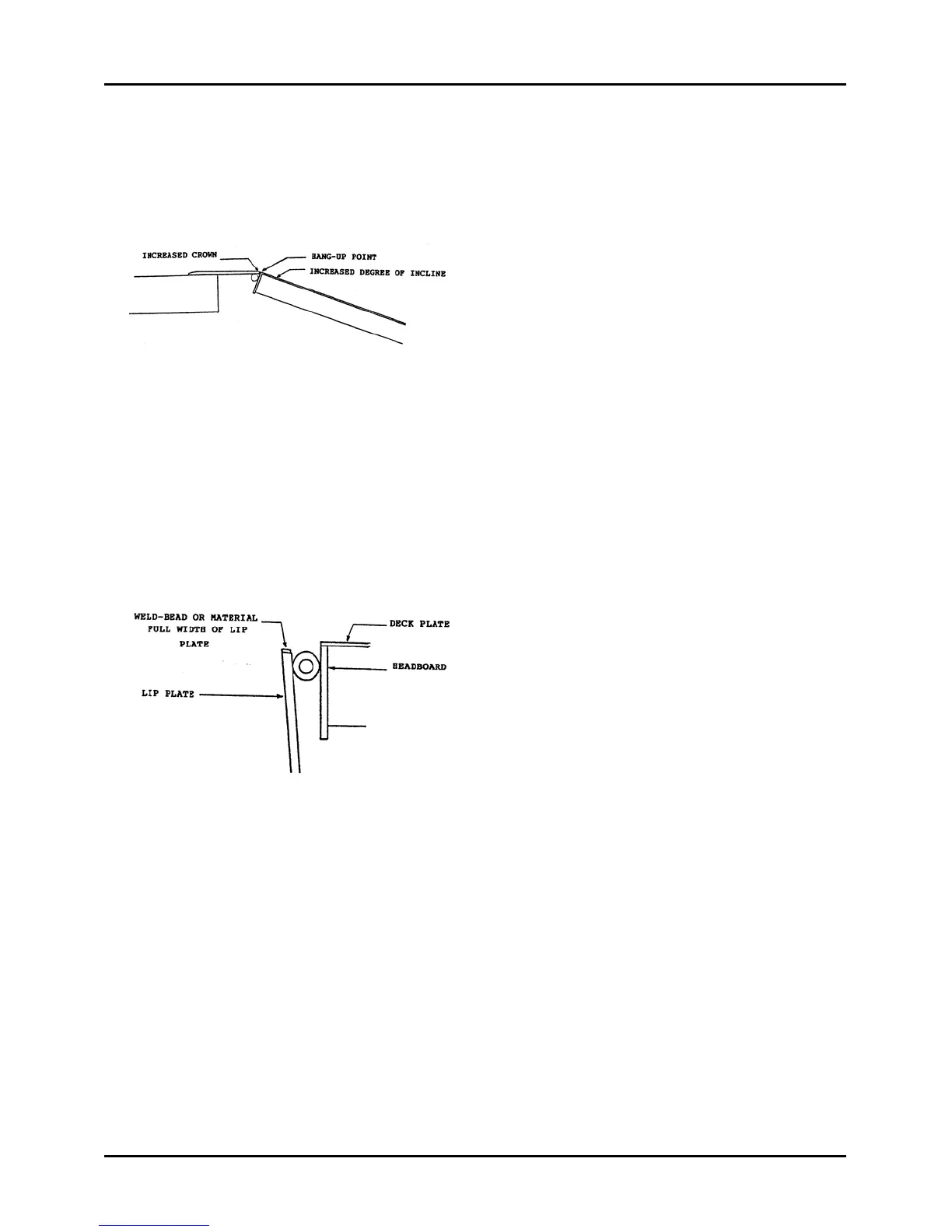

The thickness of the material added is

determined by the amount of additional

crown required. The full width of the lip

must be built up so that the load is

equally distributed across the entire

width of the headboard. An unbroken

bead of weld may be used in place of

adding material. Two or more

continuous welds may be required,

depending on the amount of additional

crown required.

When a weld bead is used as build-up

material, deposit slightly more depth

than is required and then remove the

excess material with a grinder. This

will assure an equal thickness of

build-up across the full width of the lip

with no high or low areas, and will

distribute the load equally across the

full width of the headboard.

When the desired lip crown is

achieved, position the dock leveler onto

a truck bed and place sufficient weight

on the deck to force the lip fully against

the headboard. Inspect the mating

area of lip and deck, and lightly grind

off any sharp edge that may have been

created by the change of crown. With

increase of crown this will be the upper

rear edge of the lip and will contribute

to hang-up if not removed. Do not

over-grind, remove only the sharp

edge.

Figure 91

Figure 92

Loading...

Loading...