Group 08, Section 04, Page 4 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

HOLD DOWN CABLE REPLACEMENT (Broken Cable) – cont’d

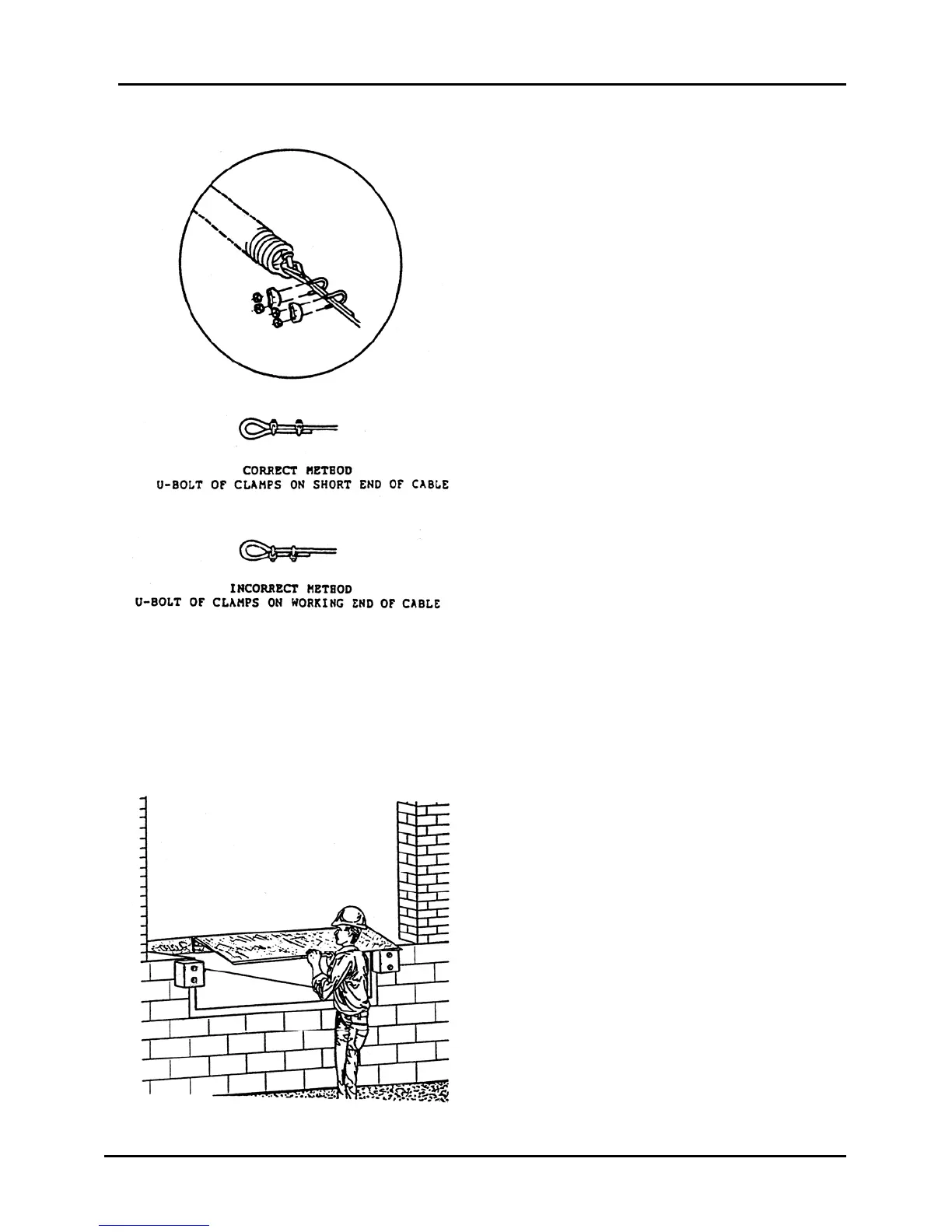

14) Feed loose cable end through lower

and upper cable rollers and through

float spring eye. Loop cable back and

install cable clamp loosely. Apply

tension to loose end of cable,

removing all slack between hold down

box and float spring. Position cable

clamp as close as possible to the float

spring while maintaining tension on

cable, and tighten securely. See

Figure 17.

15) Cut off excess cable approximately 2”

from cable clamp.

16) Carefully release the vice-grip clamp

that was holding the rewind wheel in

position.

17) Raise and lower the release handle to

assure free movement of the lock

roller and counter weight.

IMPORTANT: Do not lubricate

anything in the interior of the hold

down box.

Figure 17

18) Replace the hold down box cover, two bolts, positioning the cover 1/16” maximum

above the rewind wheel top surface. The box cover acts as a cable retainer to

prevent the holddown cable jumping off the rewind wheel, but must not interfere

with the rewind wheel rotation.

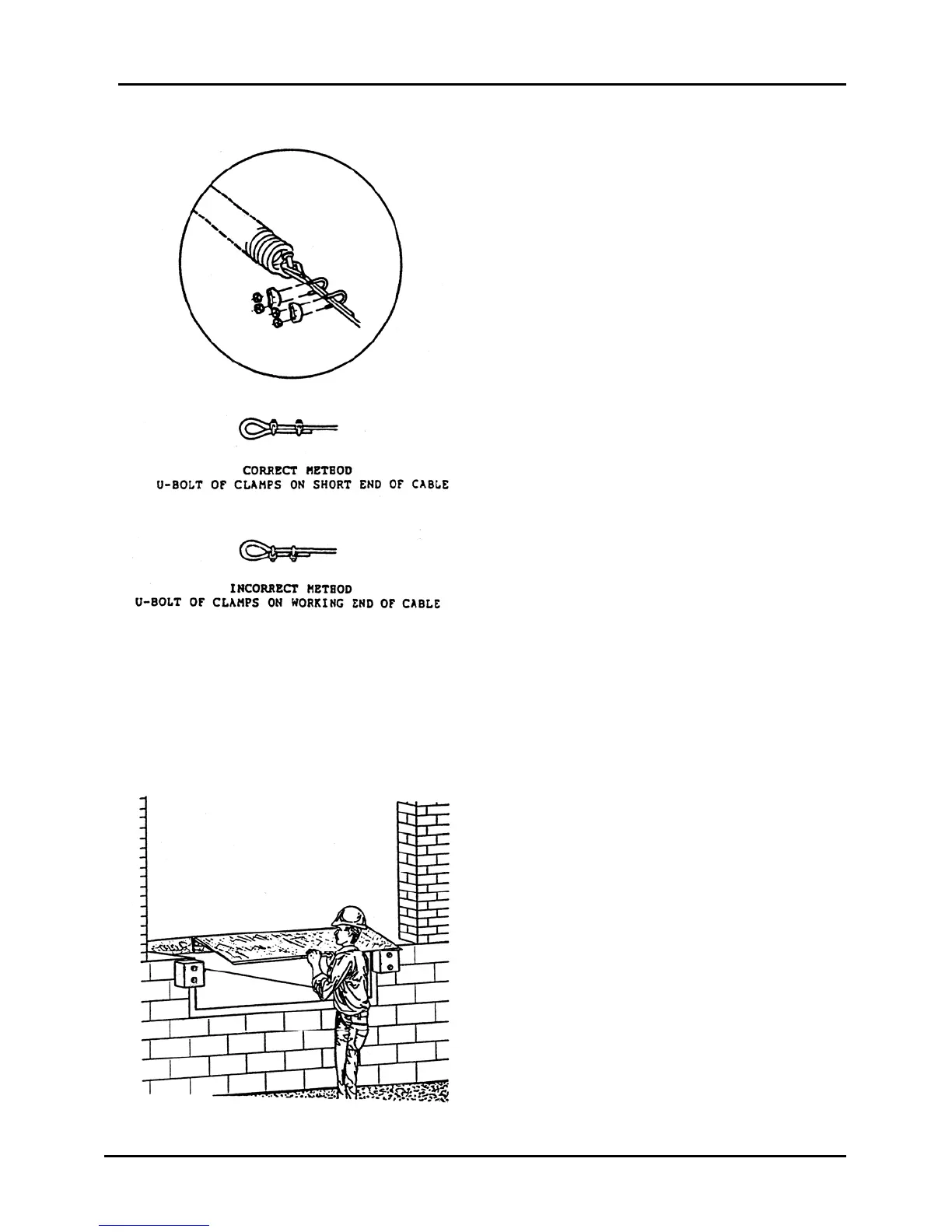

Figure 18

19) Exit pit area. Remove safety stand

and lower maintenance strut. Grasp

the leading edge of the lip and pull the

deck down to approximately 6” above

dock height. Lift the lip approximately

2” to release the lip lock and lower to

the hanging position. See Figure 18.

20) Walk the deck down to stored position.

Cycle the unit up and down several

times, stopping the deck at numerous

positions above and below dock height

to assure the hold down system will

hold the deck in any position.

Loading...

Loading...