Group 08, Section 10, Page 2 Mechanical Dock Leveler – M and FMC

Issue Date: 10/01/01, Rev, 0 (Part #038-550E)

CAM ROLLER REPLACEMENT – cont’d

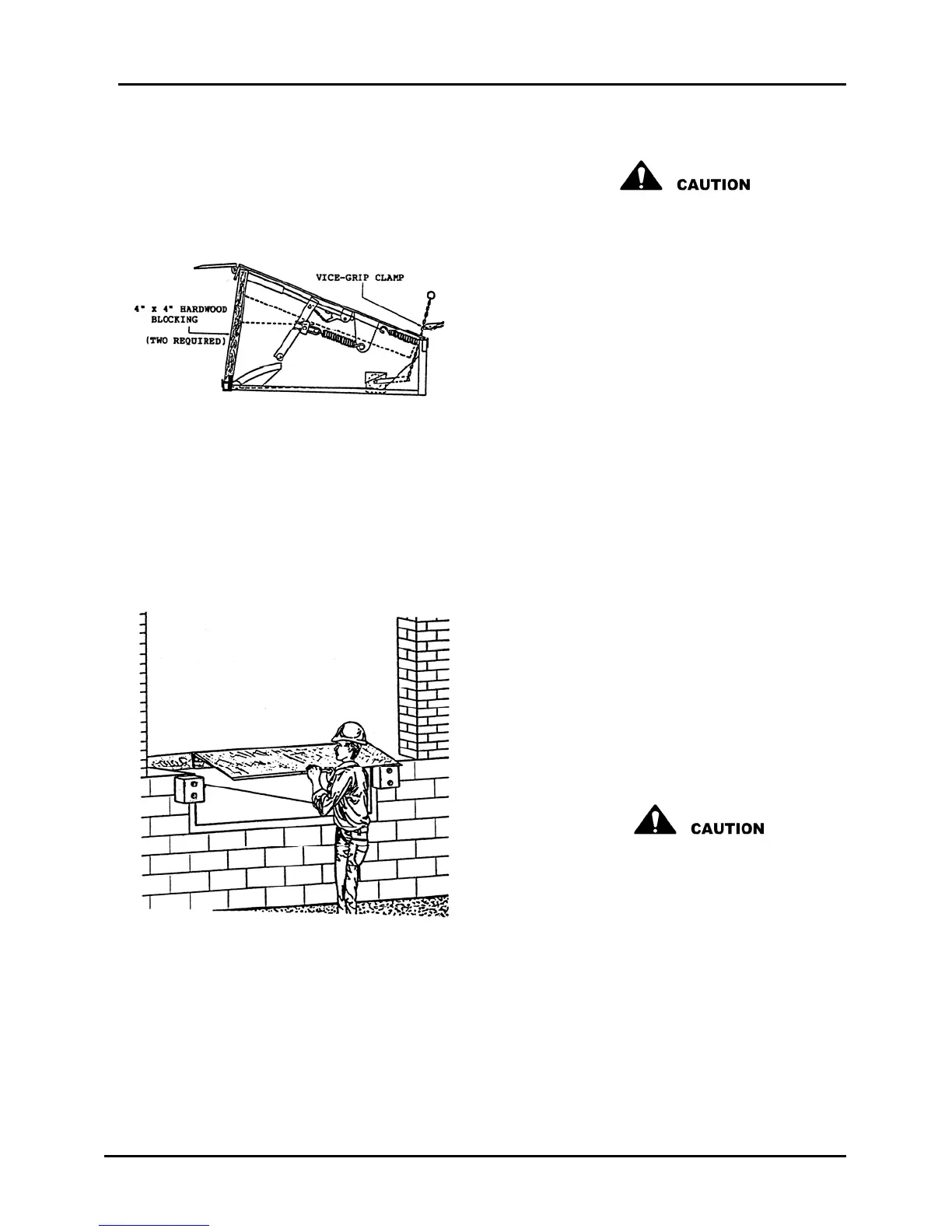

4)

When other than recommended method

of raising and / or blocking the deck is

used, Eg: fork lift trucks, overhead

crane, mechanical jack, short jack with

blocks, etc.

USE EXTREME CAUTION.

Do not work beneath the unit unless

adequate measures have been taken to

assure the deck will not lower

5) Remove and replace cam roller c/w new

bearings.

6) Remove blocking in the reverse order of

installing same, as described in

paragraphs 3 and 4, and lower the

maintenance strut.

7) Remove vice-grip clamp from release

chain, allowing the release handle to

return to its normal locked position.

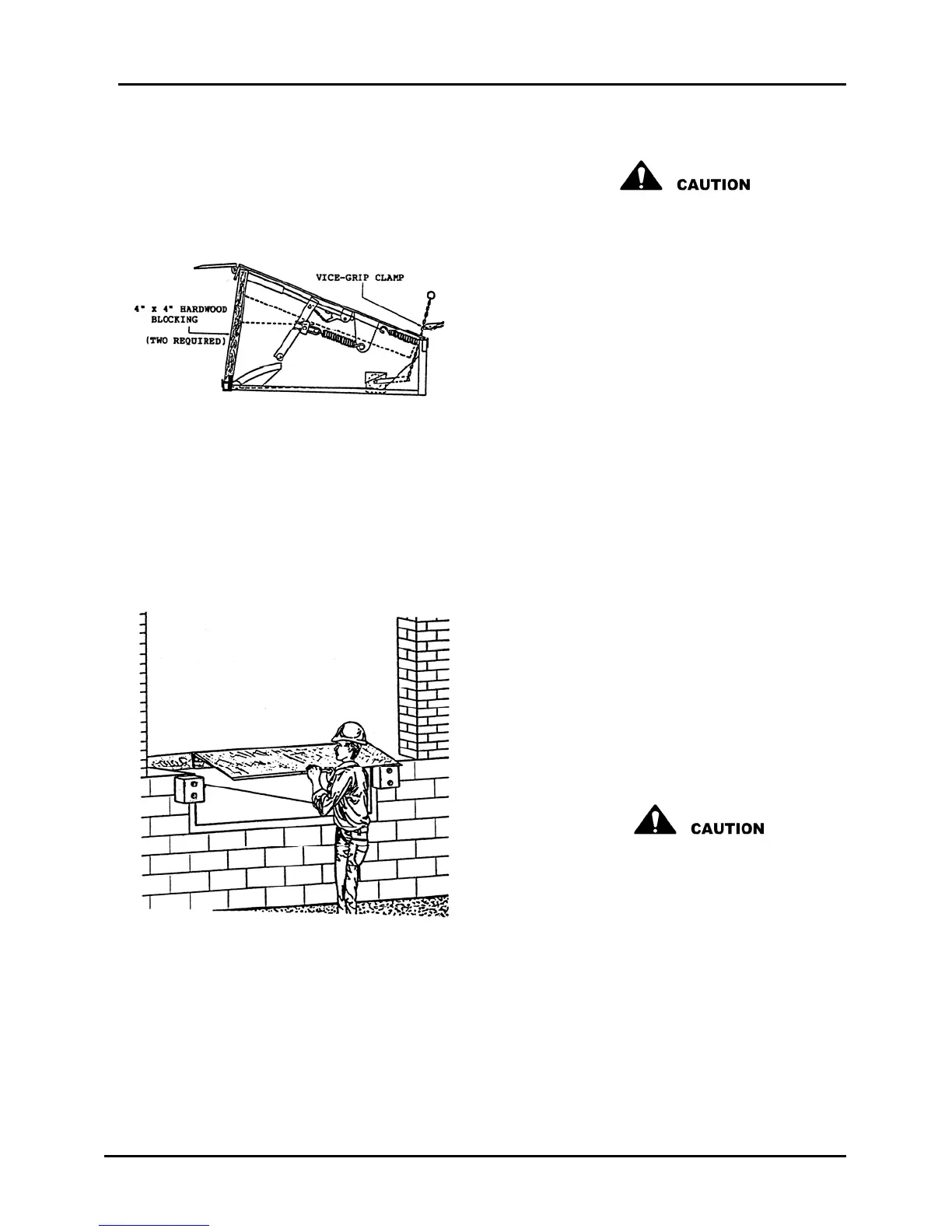

8) Walk the deck down to a position

approximately 6" above dock height.

Enter the apron area and lower the lip

by lifting approximately 2", to release the

lip lock, and lowering to hanging

position. See Figure 47.

The lip is heavy, handle with care and

be alert to pinch points.

9) Walk the deck down to its stored

position. At this time, test operate the

unit. The main spring tension may have

been increased to compensate for the

worn or broken cam roller. If the deck is

too hard to walk down and the lip

extends with excessive force, reduce

the main spring tension, equal

counterclockwise turns on each of the

four adjusting nuts, until satisfactory

operation is achieved.

Figure 46

Figure 47

Loading...

Loading...