THE FUEL SYSTEM

D

A.9300

Valves

(3)

Run the pump for about

10

minutes and turn off

the

fuel

tap.

If

the pump beats within

12

seconds,

the inlet valve

is

not seating correctly.

PrImIng

(2)

The pump should prime from dry in

10

to

15

seconds and the paraffin (kerosene) should rise in

the glass container until it runs from the overflow

drain pipe.

If

the level does not rise above the small

hole in the drain pipe, the pump

is

faulty. Initial

air bubbles should cease after a minute or two;

if

they do not, there

is

an

air leak on the suction side.

(1) Fit the

SP

adaptor set to a test rig, and a cut-away

cap to the pump. Comiect the pump to a 12-volt

battery with a voltmeter and resistance in circuit.

FUEL

PUMP

TESTING

Section D.S

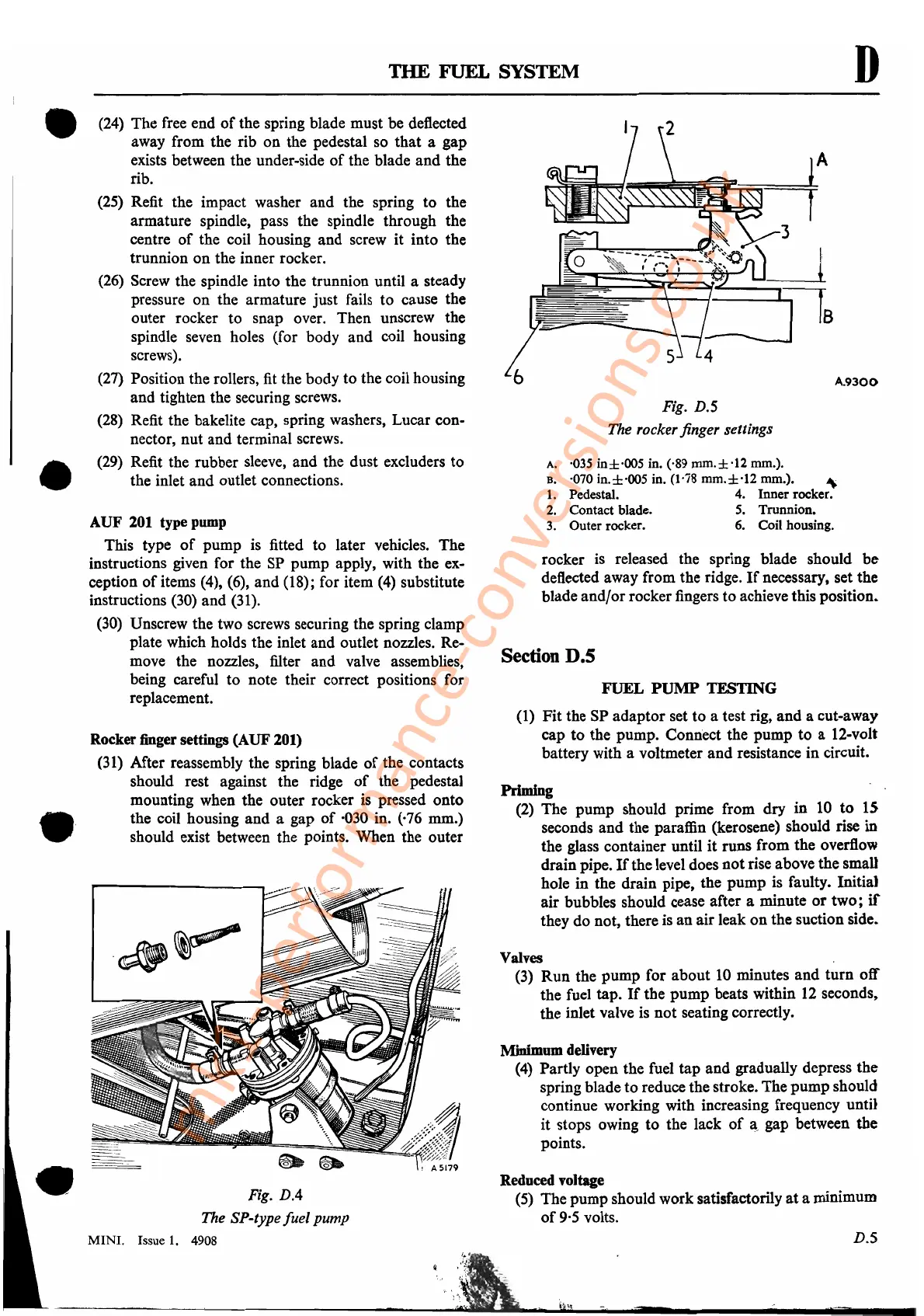

rocker

is

released the spring blade should be

deflected away from the ridge.

If

necessary, set the

blade and/or rocker fingers to achieve this position.

A. '035 in±·OO5 in. ('89

mm.±

'12 mm.).

B. ·070 in.±·OO5 in. (1'78

mm.±·12

mm.). ""

1.

Pedestal. 4. Inner rocker.

2.

Contact blade.

5.

Trunnion.

3. Outer rocker. 6. Coil housing.

Fig. D.S

The rocker finger settings

D.S

Minimum delivery

(4)

Partly open the fuel tap and gradually depress the

spring blade to reduce the stroke. The pump should

continue working with increasing frequency until

it stops owing to the lack

of

~>

gap between the

points.

Reduced voltage

(5)

The pump should work satisfactorily

at

a minimum

of

9·5

volts.

Rocker finger settings (AUF 201)

(31)

After reassembly the spring blade

of

the contacts

should rest against the ridge

of

the pedestal

mounting when the outer rocker

is

pressed onto

the coil housing and a gap

of

'030 in. ('76 mm.)

should exist between the points. When the outer

(24)

The

free

end

of

the spring blade must be deflected

away from the rib on the pedestal so that a gap

exists between the under-side

of

the blade and the

rib.

(25)

Refit the impact washer and the spring to the

armature spindle, pass the spindle through the

centre of the coil housing and screw it into the

trunnion on the inner rocker.

(26)

Screw

the spindle into the trunnion until a steady

pressure on the armature just fails to cause the

outer rocker to snap over. Then unscrew the

spindle seven holes (for body and coil housing

screws).

(27)

Position the rollers,

fit

the body to the coil housing

and tighten the securing screws.

(28)

Refit the bakelite cap, spring washers, Lucar con-

nector, nut and terminal screws.

(29)

Refit the rubber

sleeve,

and the dust excluders to

the inlet and outlet connections.

AUF

201 type pump

This type

of

pump

is

fitted to later vehicles. The

instructions given for the

SP

pump apply, with the

ex-

ception

of

items

(4),

(6),

and (18); for item

(4)

substitute

instructions

(30)

and

(31).

(30)

Unscrew the two screws securing the spring clamp

plate which holds the inlet and outlet nozzles. Re-

move the nozzles, filter and valve assemblies,

being careful to note their correct positions for

replacement.

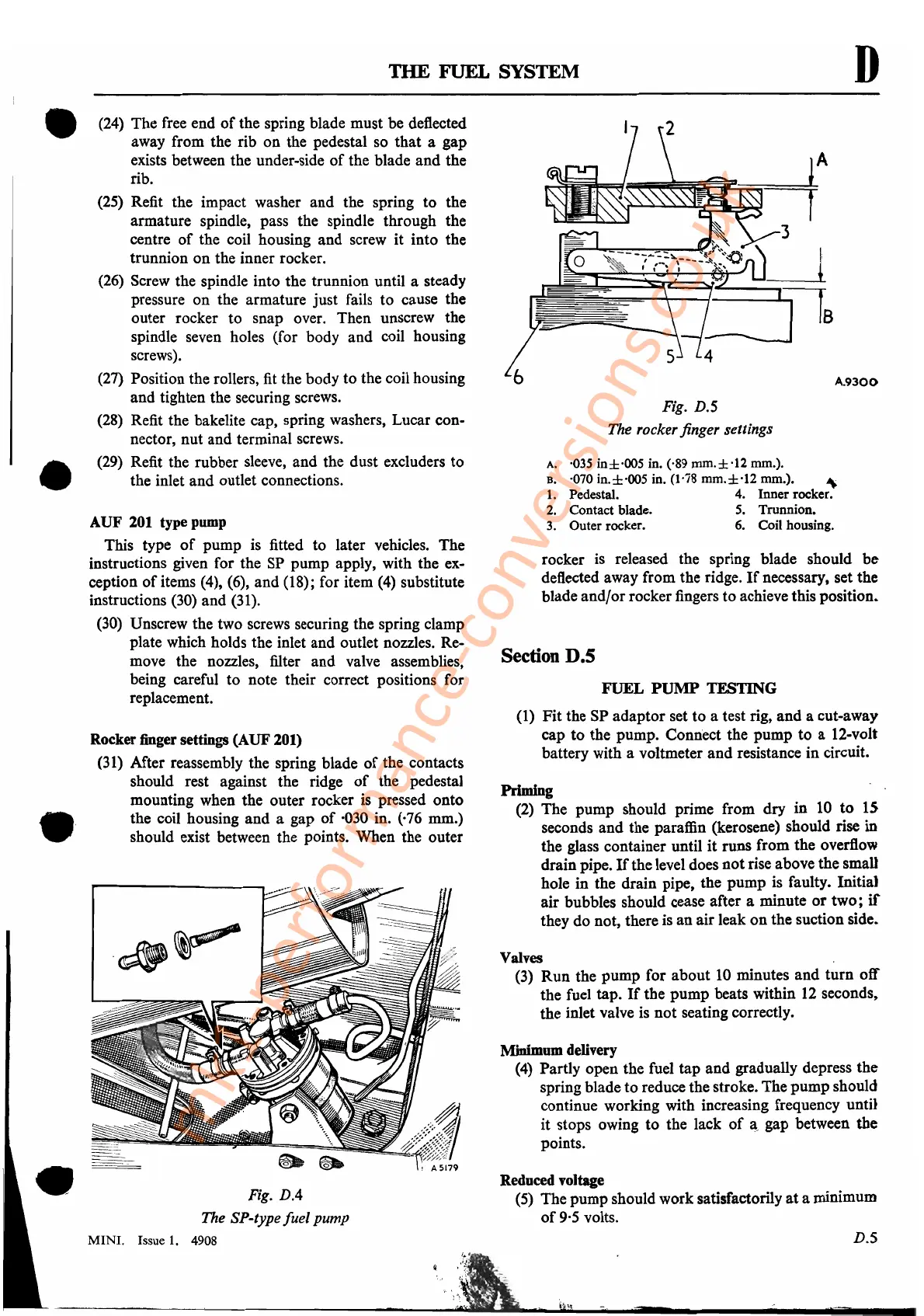

Fig. D.4

The SP-type

fuel

pump

MINI. Issue

1.

4908

•

•

•

•

mk1-performance-conversions.co.uk

Loading...

Loading...