F

THE

TRANSMISSION

A

•

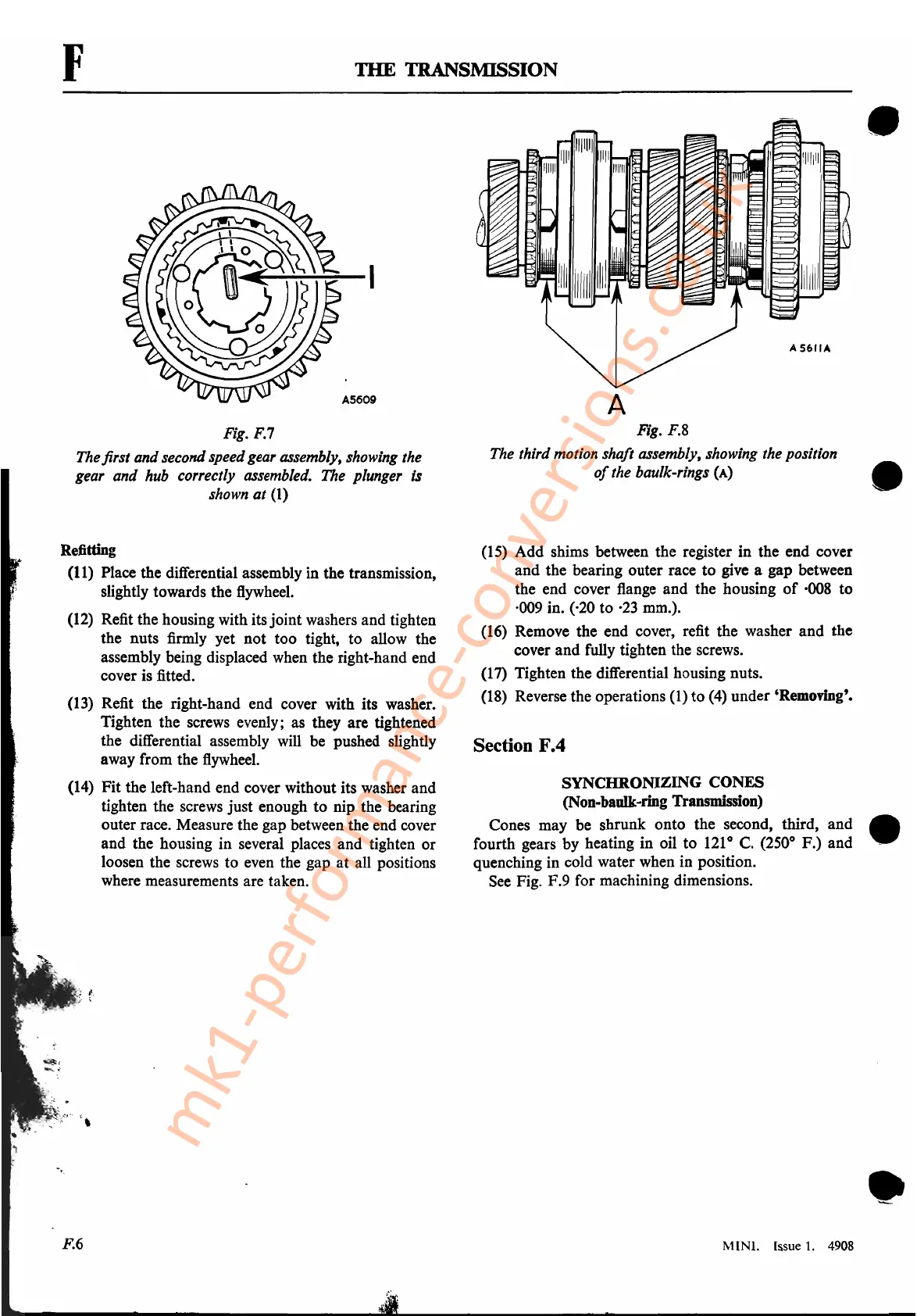

Fig. F.7

The first and second speedgear assembly, showing the

gear and hub correctly assembled. The plunger is

shown

at

(1)

Refitting

(11) Place the differential assembly in the transmission,

slightly towards the

flywheel.

(12)

Refit the housing with its joint washers and tighten

the nuts firmly yet not too tight, to allow the

assembly being displaced when the right-hand end

cover is fitted.

(13)

Refit the right-hand end cover with its washer.

Tighten the screws evenly; as they are tightened

the differential assembly

will

be pushed slightly

away from the

flywheel.

(14)

Fit the left-hand end cover without its washer and

tighten the screws just enough

to

nip the bearing

outer race. Measure the gap between the end cover

and the housing in several places and tighten or

loosen the screws to even the gap at all positions

. where measurements are taken.

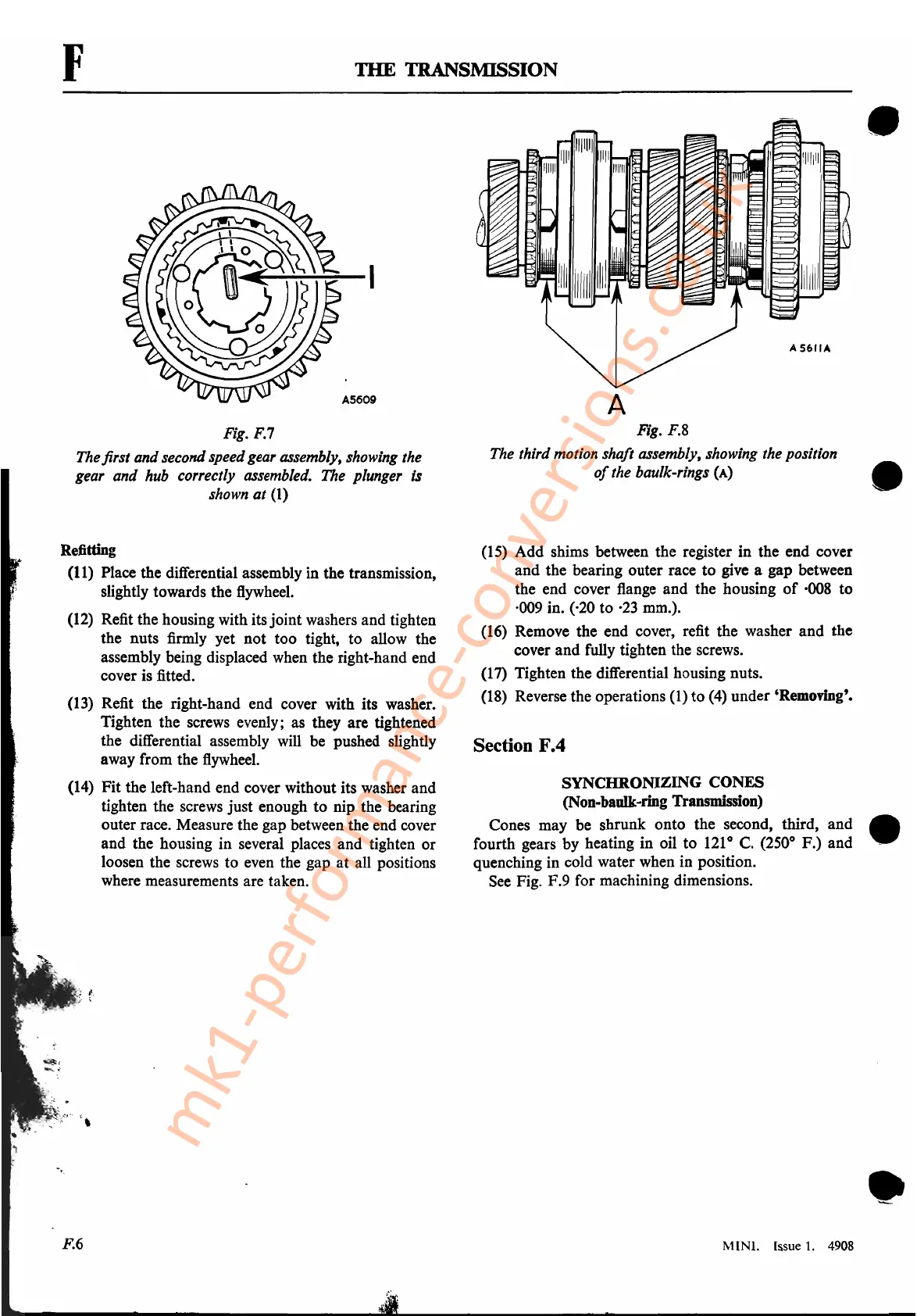

Fig. F.8

The third motion shaft assembly, showing the position

of

the baulk-rings

(A)

•

(15)

Add shims between the register in the end cover

and the bearing outer race to give a gap between

the end cover flange and the housing

of

·008

to

·009 in. (·20 to

·23

mm.).

(16)

Remove the end cover, refit the washer and the

cover and fully tighten the screws.

(17) Tighten the differential housing nuts.

(18)

Reverse the operations

(1)

to

(4)

under 'Removing'.

Section F.4

SYNCHRONIZING CONES

(Non-baulk-ring Transmission)

Cones may be shrunk onto the second, third, and •

fourth gears by heating in oil

to

121

0

C. (250° F.) and

....

quenching in cold water when in position.

See

Fig. F.9 for machining dimensions.

•

MINI. Issue

1.

4908

mk1-performance-conversions.co.uk

Loading...

Loading...