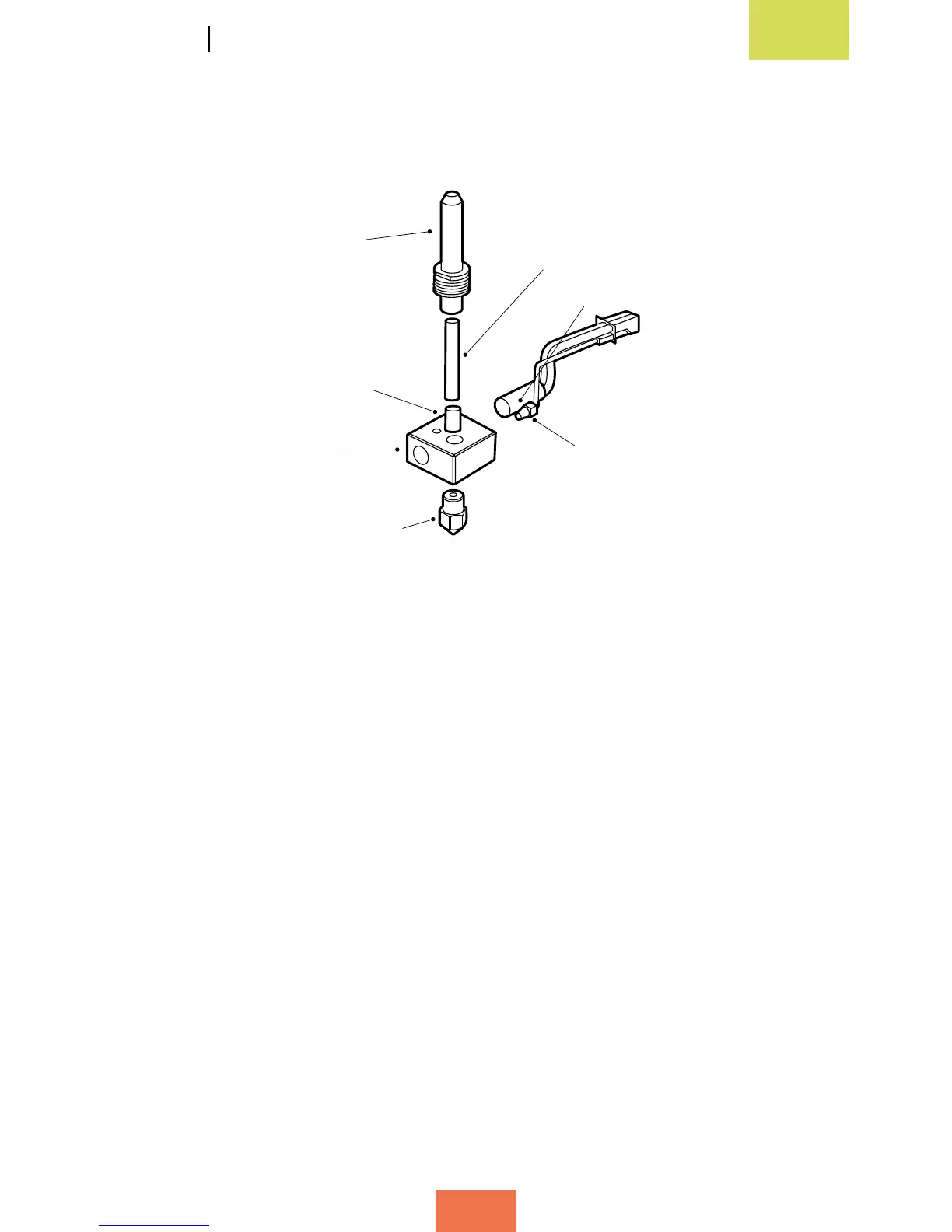

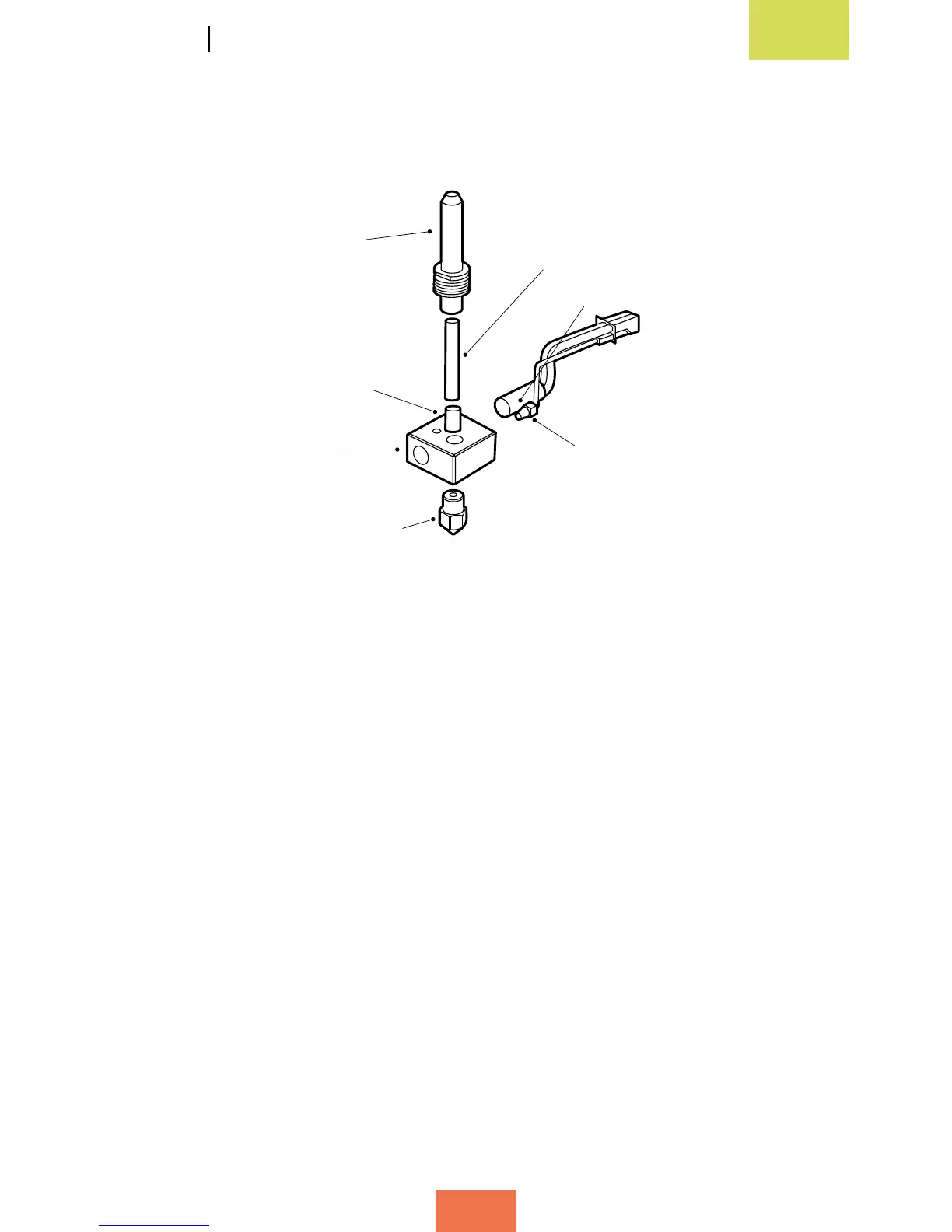

Hot-End

The Hot-End heats the filament so that it can be extruded. It is comprised of the

following parts:

• Nozzle: the polymer is extruded from here. The nozzle is made of brass and has

an opening of 0.4 mm.

• Die: this is where the polymer is melted, and is the part that reaches the highest

temperatures (around 210 °C). It is made from 6082-grade aluminium.

• Screw: this a threaded bar positioned above the die and serves to guide the

lament. The section nearest the die has ns in order to help dissipate the heat

generated by the die.

• Polytetrauoroethylene (PTFE) tube: this is located inside the screw and helps

prevent friction between the lament and the screw.

• Bushing: this is located inside the screw beneath the PTFE tube. It keeps the

tube in place and prevents it from sliding towards the die.

• 100K thermistor: this device measures the temperature of the die.

• Ceramic heater (12 V, 40 W): heats the die to the temperature required for

extruding the lament.

Figure 5.4 Constituent parts of the Hot-End

Ceramicheater

100Kthermistor

Nozzle

Bushing

Screw

Die

PTFE tube

Loading...

Loading...