1-12

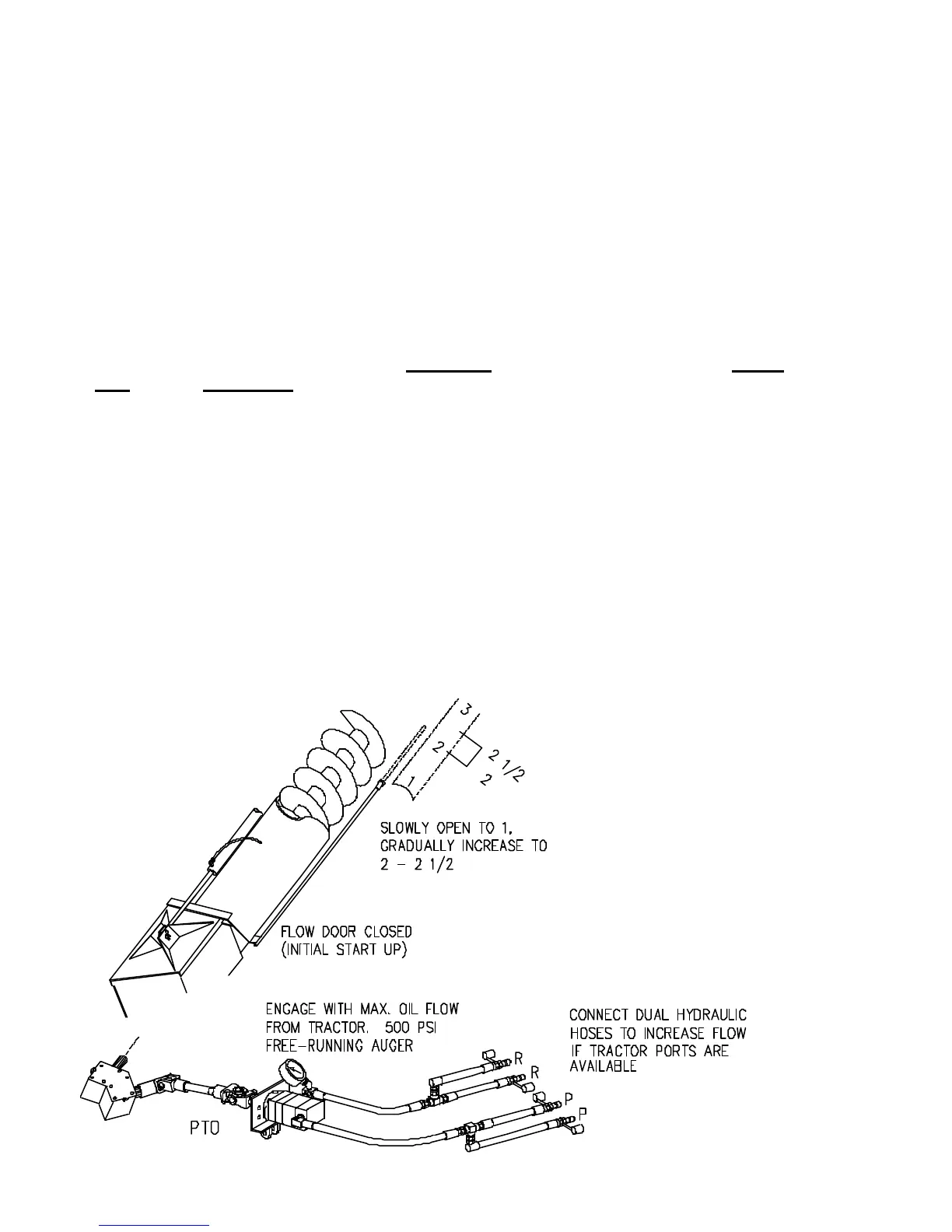

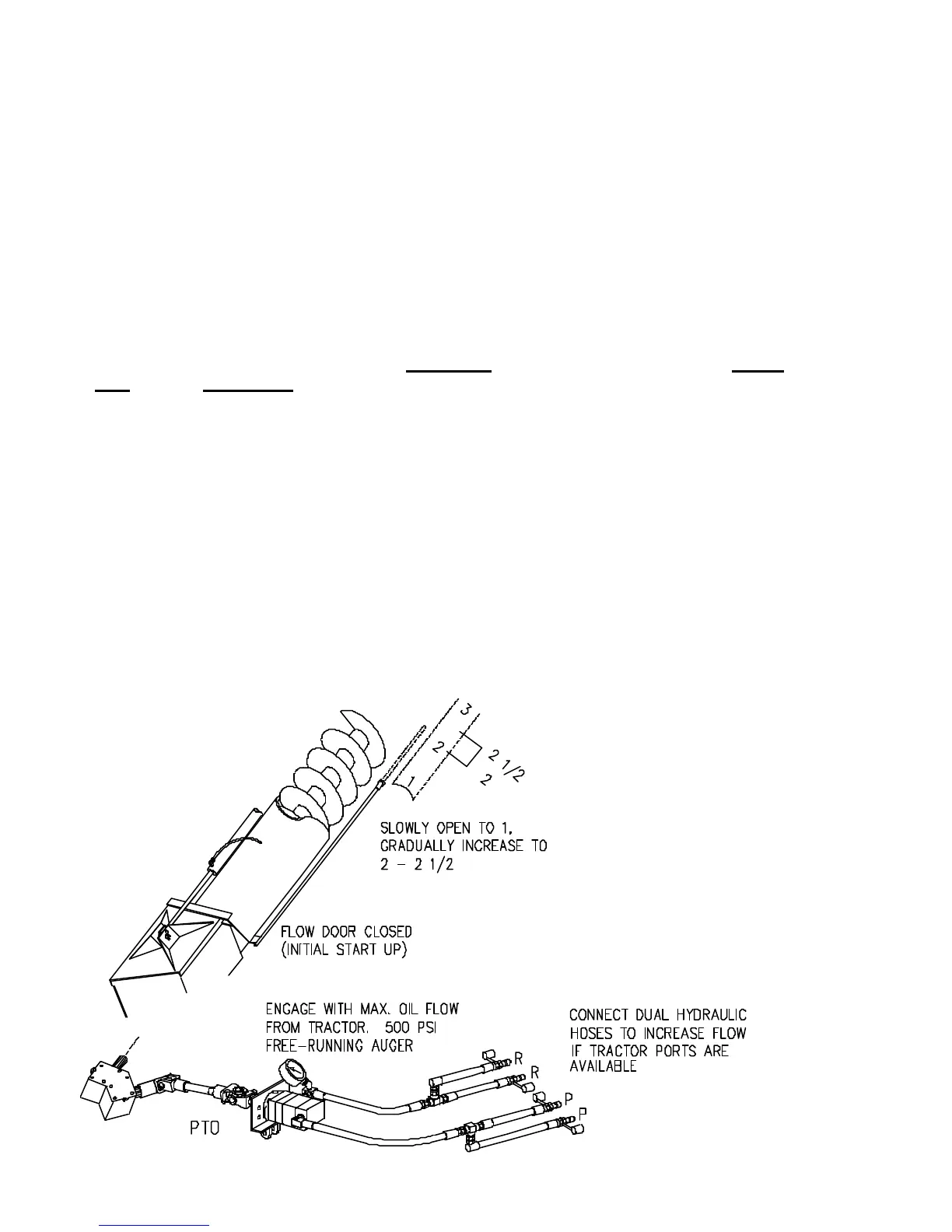

HYDRAULIC AUGER OPERATION

For PTO & DIRECT DRIVE Applications

250946

1. Initial start-up: Flow Door is to be closed.

2. With flow door closed, engage hydraulic motor with maximum oil flow from

tractor. NOTE: Free running auger oil pressure will range 500 PSI or less.

3. The pressure gauge will register system work load as flow door is opened.

Slowly open flow door to #1 setting on auger tube decal gauge. While

monitoring the auger discharge rate and hydraulic pressure, gradually increase

flow door opening to approximately 2 - 2 1/2 setting. Watch the pressure gauge

and stop opening door once pressure reaches 2000 PSI.

4. Peak performance is obtained by matching your highest continuous auger

rpm to the flow door opening setting. It is necessary to initially monitor the

auger speed and adjust the flow door UP or DOWN to arrive at the optimum

output performance. If the flow door is opened too wide, the oil pressure will

rise, but the GPM and the hydraulic motor RPM could slow down - resulting in

less auger output. Also if the tractor has a higher GPM output, it is possible that

the flow door could be opened wider and still maintain performance.

5. Bushels-per-minute output depends on the following factors:

a. Oil flow (GPM) from tractor.

b. Flow door opening setting.

c. Grain moisture content.

6. The hydraulic motor is capable of handling 32 to 35 GPM. If extra hydraulic

ports are available on the tractor, it is possible to increase oil flow to the

hydraulic motor by teeing together two pressure ports to the single pressure

hose, and teeing two hoses from return hose to the tractor return ports.

• 09-09-96

Loading...

Loading...