1-19

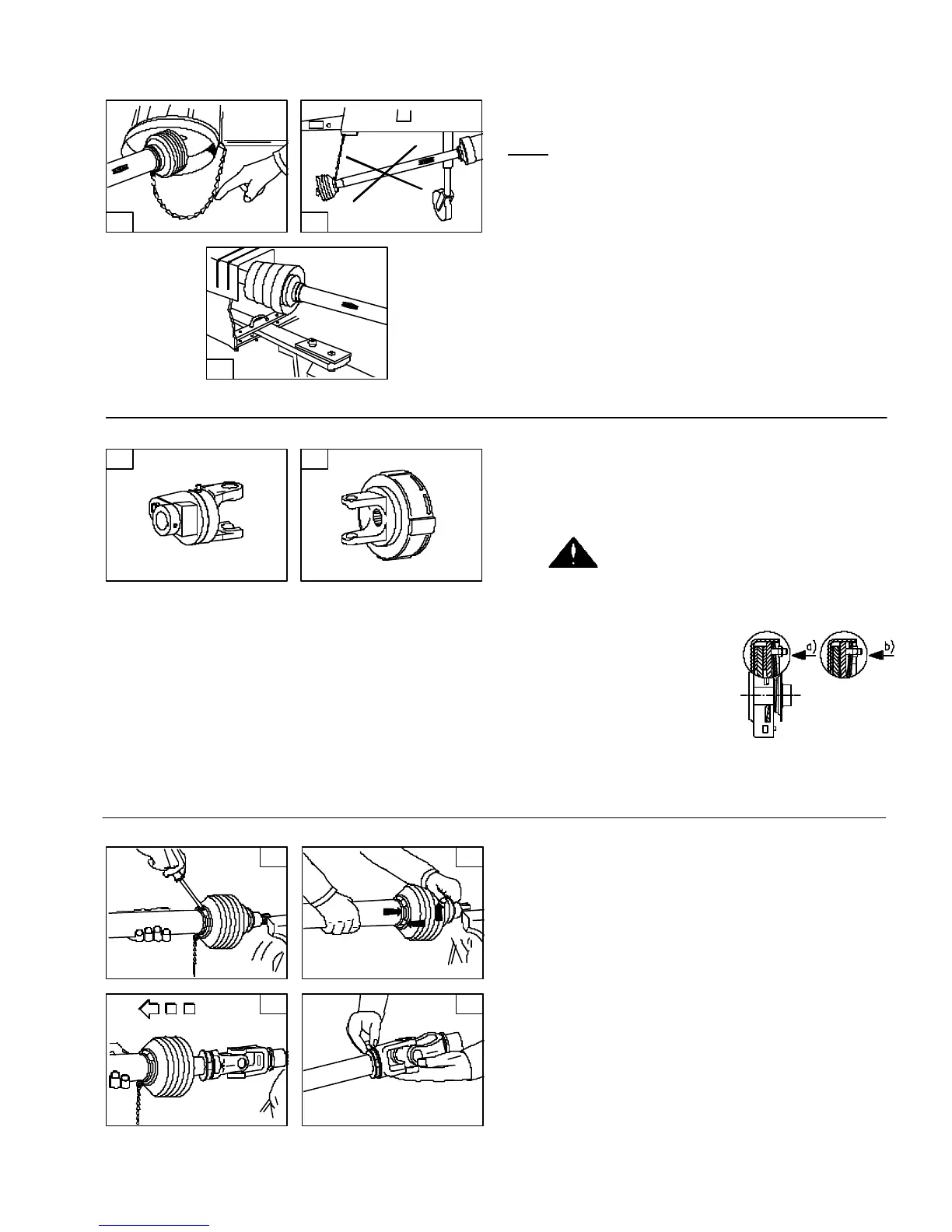

G. Chains (Figs. G1 - G3)

NOTE: The chain is intended to prevent the shield

from rotating against non-moving parts and thereby

preventing shield damage. A properly installed chain

will increase the service life of the shield.

1. Chains must be fitted so as to allow sufficient

articulation of the shaft in all working positions.

Care must be taken to be sure that chain does not

become entangled with drawbar hitch or other

restrictions during operation or transport of

machine.

2. The PTO drive shaft must not be suspended from

the chain.

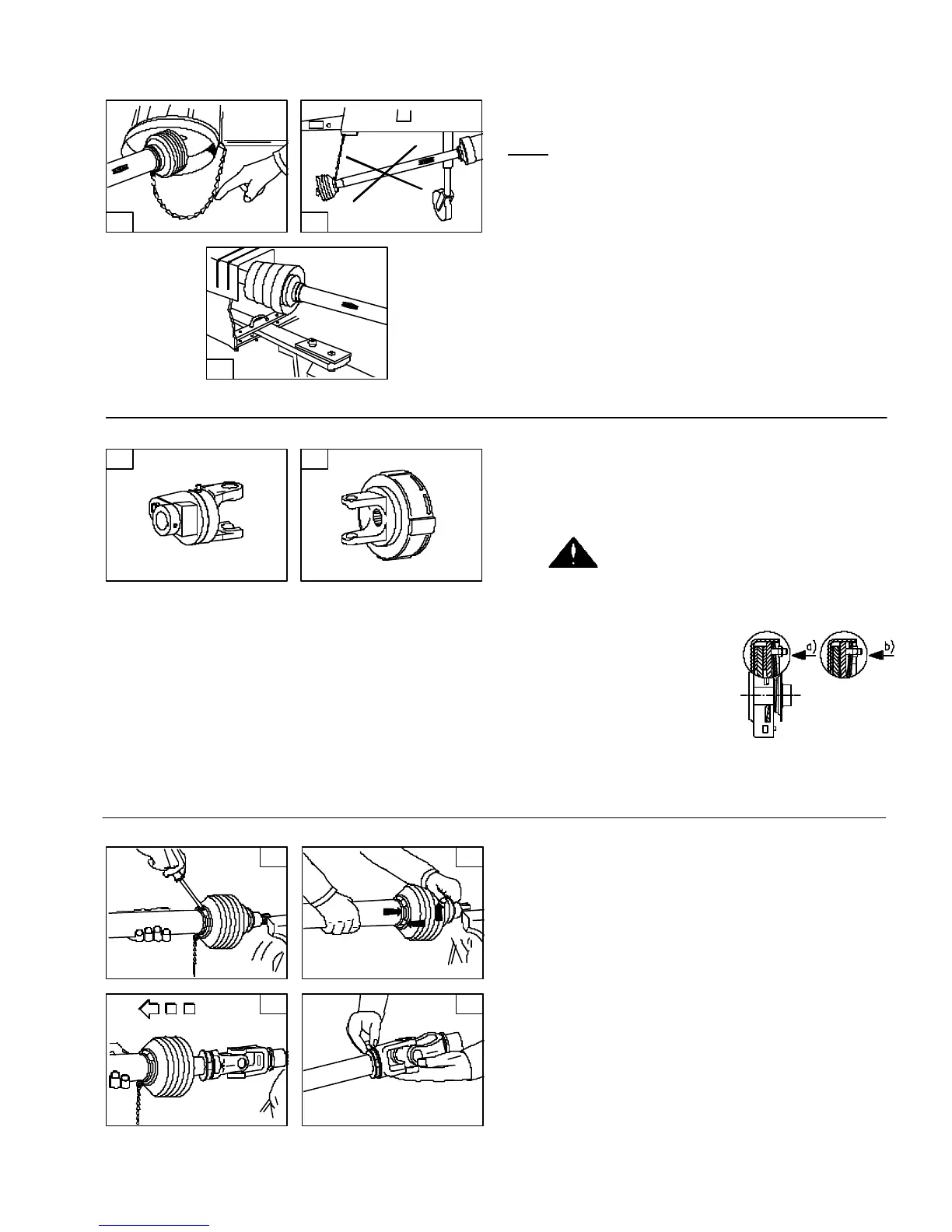

J. To dismantle guard: (Figs. J1 - J4)

1. Remove locking screw.

2. Align bearing tabs with cone pockets.

3. Remove half-guard.

4. Remove bearing ring.

G2

2. Friction clutches:

When overload occurs, the torque is limited and

transmitted constantly during the period of slip-

ping. Short-duration torque peaks are limited.

Prior to first utilization and after long

periods out of use, check working of disk

clutch.

a. Tighten nuts until friction disks are released.

Rotate clutch fully.

b. Turn nuts fully back.

Now the clutch is ready

for use.

Fig. H2 shown.

Avoid extended and frequent slippage of overload

clutches.

H. Shear bolt and friction clutches (Figs. H1 - H2)

1. Shear bolt clutches:

When the torque is exceeded, power flow is

interrupted due to the bolt shearing. The torque

is re-established by replacing the broken shear

bolt. Use only the bolt specified in the operator's

manual for replacement.

G1

G3

H1

H2

J2

J1

J3

J4

250968H

250968G

250968J

Loading...

Loading...