1-17

C. Maximum joint angles:

1. Joint (standard type)

Continuous operation 25

o

Short duration 45

o

Stationary 90

o

2. Wide-angle CV joint

Continuous operation 25

o

Short duration 70/80

o

Stationary 70/80

o

Check shaft articulation and clearance zone! Joint

articulations of more than 70/80 degrees leads to

damage.

C2

C1

Contact between PTO drive shaft and tractor or

implement (e.g. three point hitch, drawbar) leads to

damage.

}

(depending on design)

(depending on design)

Ensure equal joint

angles! Switch off

PTO if joint angles

are too large and

unequal!

To avoid injury do not clean, adjust, unclog, or

service PTO driven equipment when the tractor en-

gine is running.

Never exceed the recommended operating speed for

the particular equipment in use.

PTO drive shafts must only be used for their in-

tended purpose.

PTO drive shafts, clutches and freewheels are de-

signed for specific machine types and power require-

ments. They must not be replaced by other models.

NOTE: The tractor and implement manufacturers'

operating instructions.

Ensure that the PTO shaft is securely connected.

This Safety Alert Symbol means Attention!

Become Alert! Your safety is involved!

OPERATING THE PTO

When finishing operation of PTO driven equipment,

shift PTO control to neutral, shut off the engine and

wait until the PTO stops before getting off the tractor

and disconnecting the equipment.

Do not wear loose clothing when operating the power

take-off, or when near rotating equipment.

When operating stationary PTO driven equipment,

always apply the tractor parking brake lock and block

the rear wheels front and back.

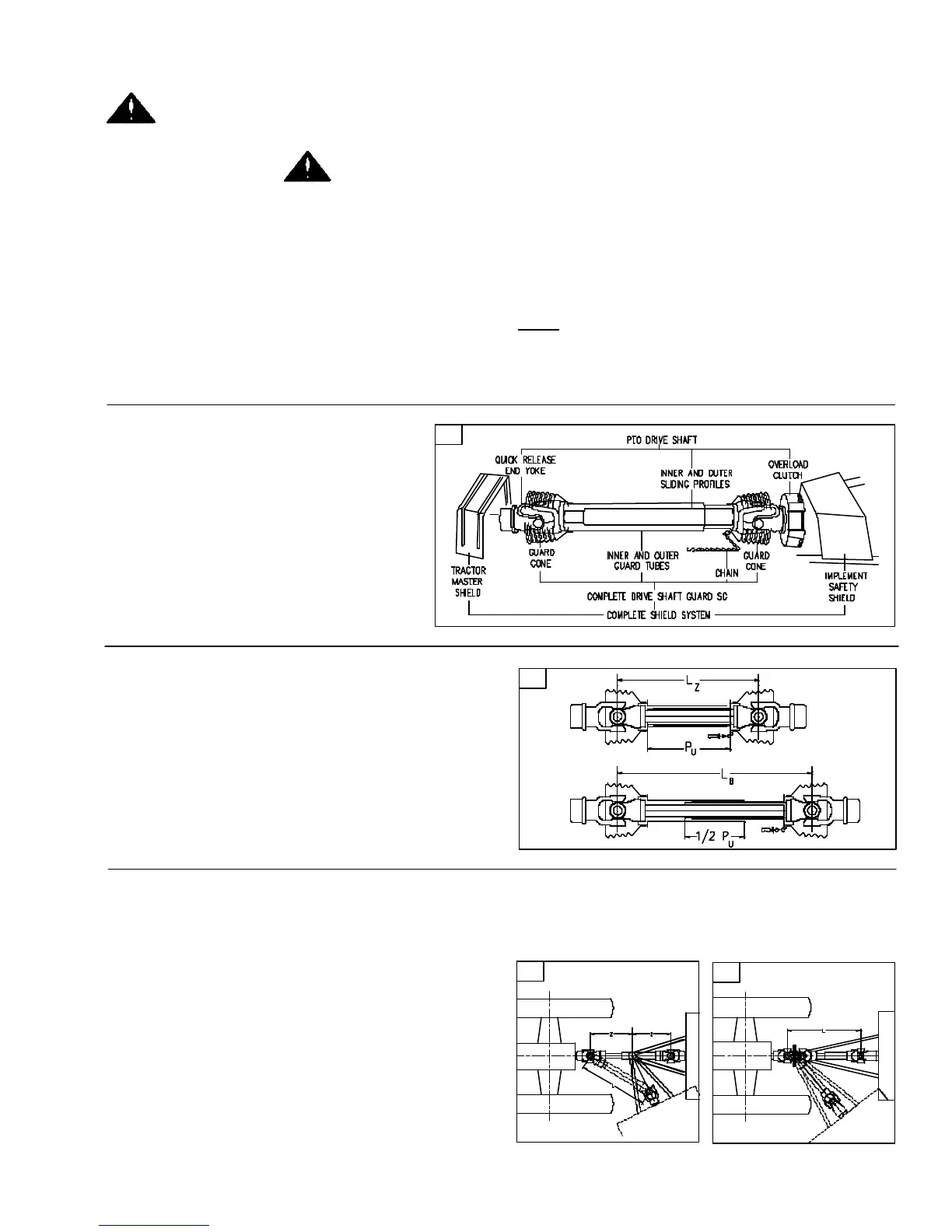

PTO SHAFT & CLUTCH

A. Only use a completely shielded drive

system:

PTO drive systems with complete

shielding, include the tractor master

shield and implement shielding installed

all the time. If any component of the

shield system has been removed for

any reason it, or a repair part, must be

installed before operation.

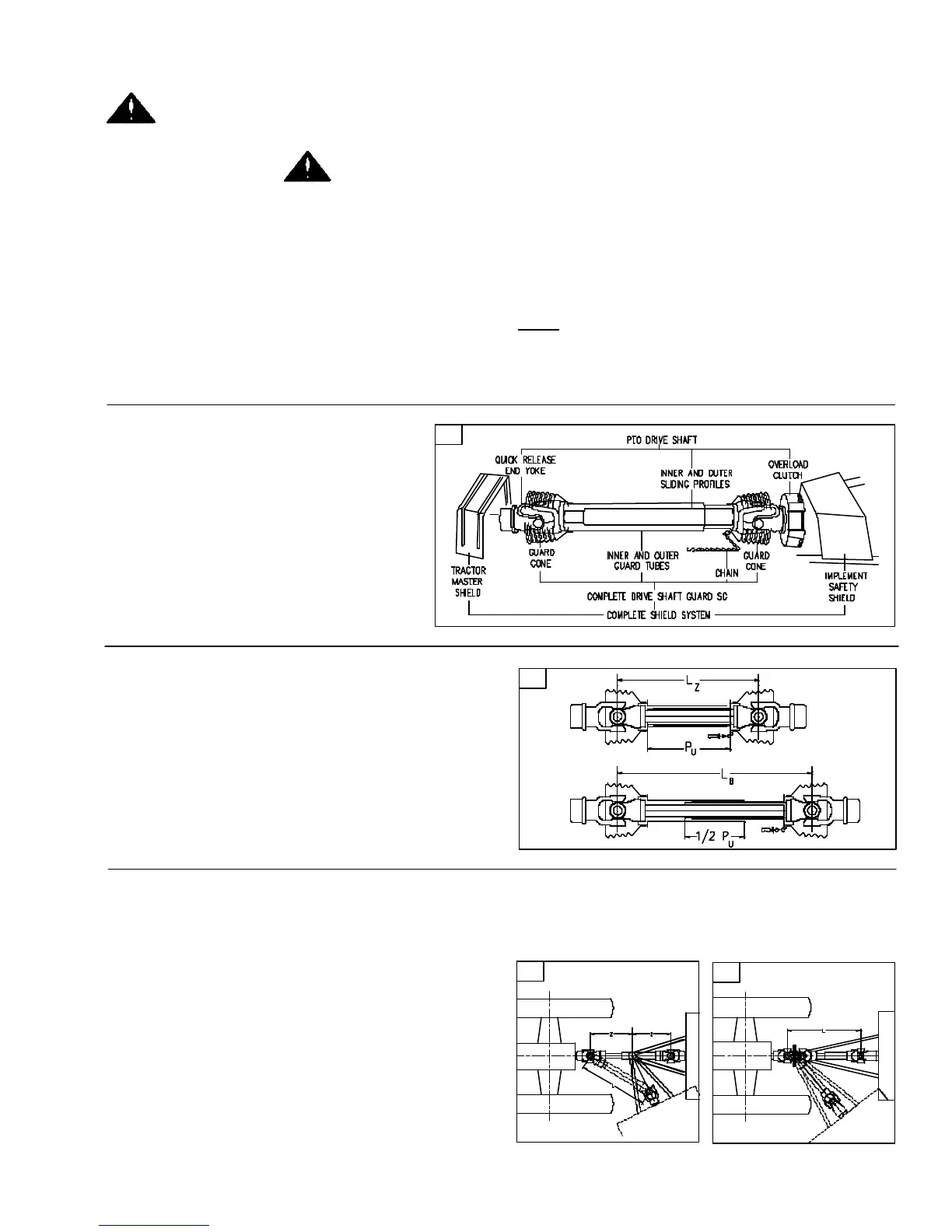

BB. Note the maximum operating length L

B

!

Try to obtain the greatest possible overlap without

bottoming out in the maximum operating condi-

tion. In its working position, the PTO drive shaft

should not be extended by more than half the

telescoping member overlap P

U

available when

fully compressed L

Z

. (See diagram on inside

cover).

A

250968A

250968C

250968B

Loading...

Loading...