SnackFix 2016-08 47

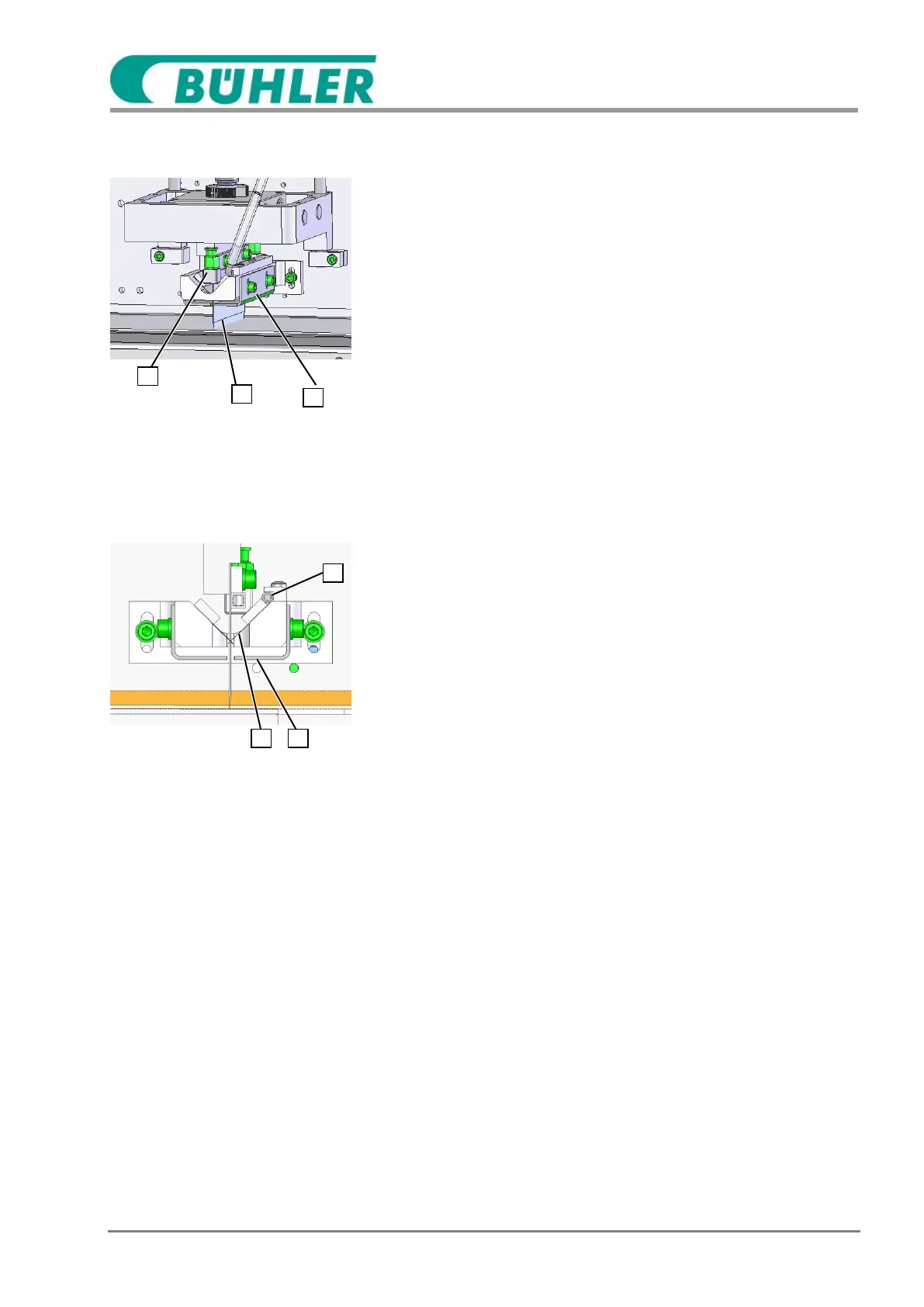

The knife (1) of the cutting machine is driven by a servo motor and

cuts on the transport belt. The arriving strands are cut across the mov-

ing direction of the belt.

In addition to the vertical cutting movement, the belt performs a hori-

zontal knife following movement in working direction.

The cutting length is adjusted at the control panel. The cutting fre-

quency is displayed at the control panel. It depends on the adjusted

cutting length and on the belt speed. The cutting machine can be at-

tuned to the working speed of the production line without changing the

cutting length.

A downholder (2) with knife cleaning device prevents the product

mass from being lifted by the knife and sticking on it.

The cutting beam (3) is temperature-controlled and prevents the prod-

ucts from sticking on the knife.

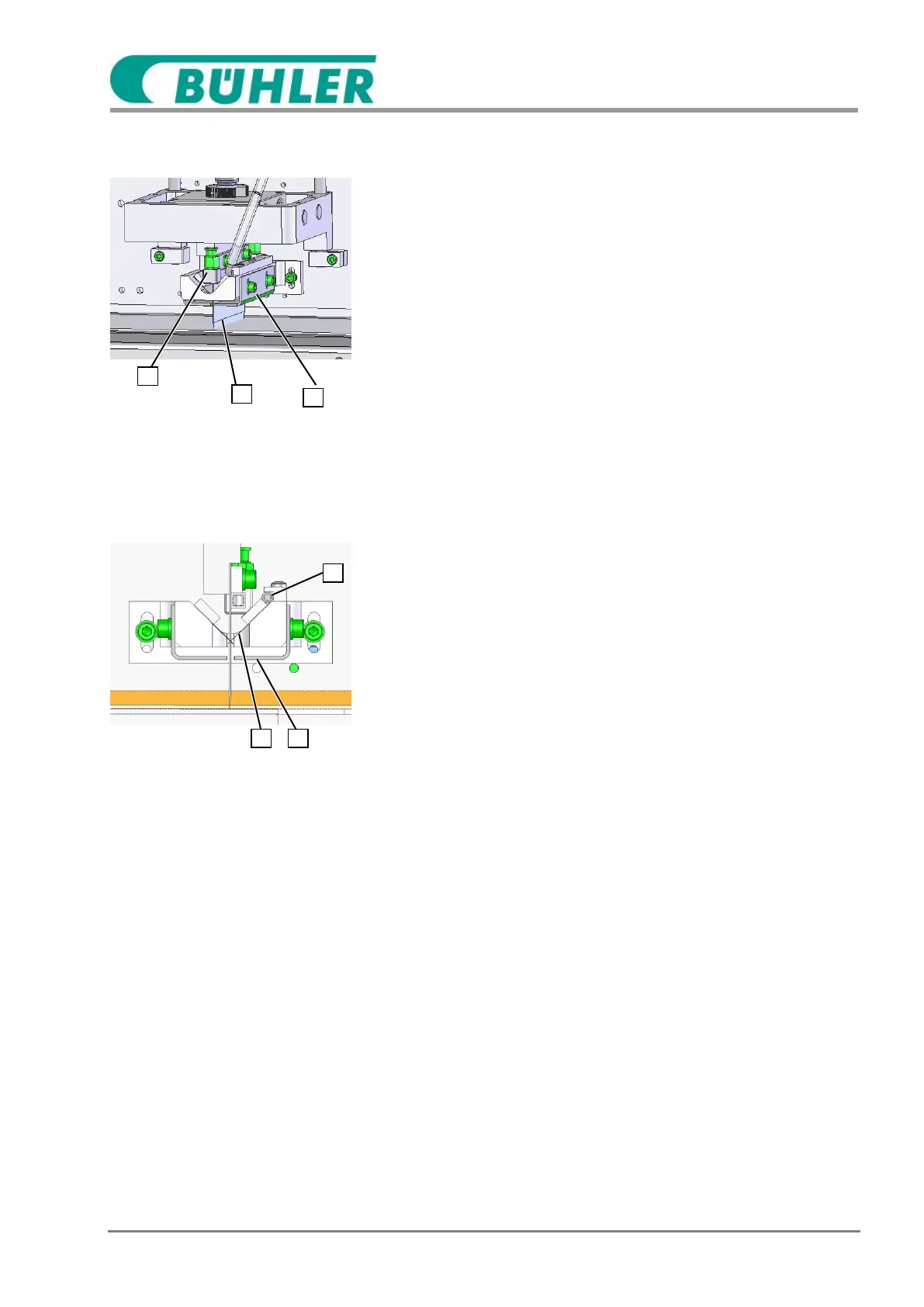

The downholder is adjustable in height. There are two angles (1) on

the bottom side. The downholder should be adjusted approx. 2 –

3 mm higher than the product which is to be cut. Two scrapers (2) are

installed at the downholder. The scrapers clean the knife after every

cut. At the same time the release agent is applied over the complete

length of the knife through a distributor pipe (3). The release agent

serves for separating the mass from the knife. Depending on the re-

quired amount, the release agent is dosed by the drip oiler installed at

the container.

The following release agents can be used depending on the product

mass:

Diluted alcohol (50%)

Low viscosity food grade oil

Sugar dissolving oil, etc.

The transport belt is driven by a servo motor via a bevel gear.

The transport belts consist of a non-extensible, dimensionally stable

polyester cloth with additional silicon coating. The belt is rot-proof and

food-safe.

The transport belt is kept in track on the machine table by belt guide

rails. Belt tensioning devices allow for regulating the belt tension. One

belt edge can be hinged upwards ( Fig. 14: Belt edge on page 47).

Loading...

Loading...