Chore-Tronics® 2 Control Overview of Screens

MT1843B

55

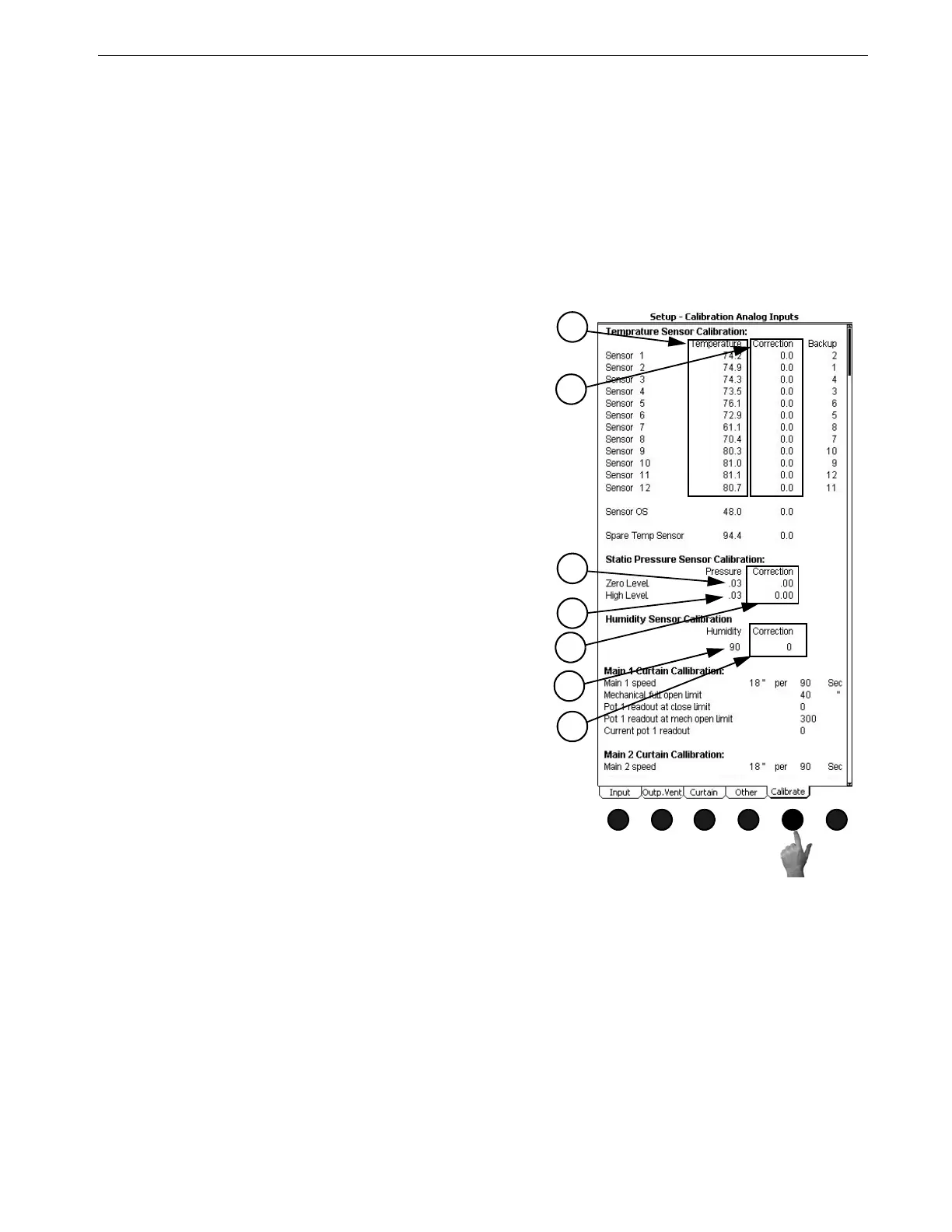

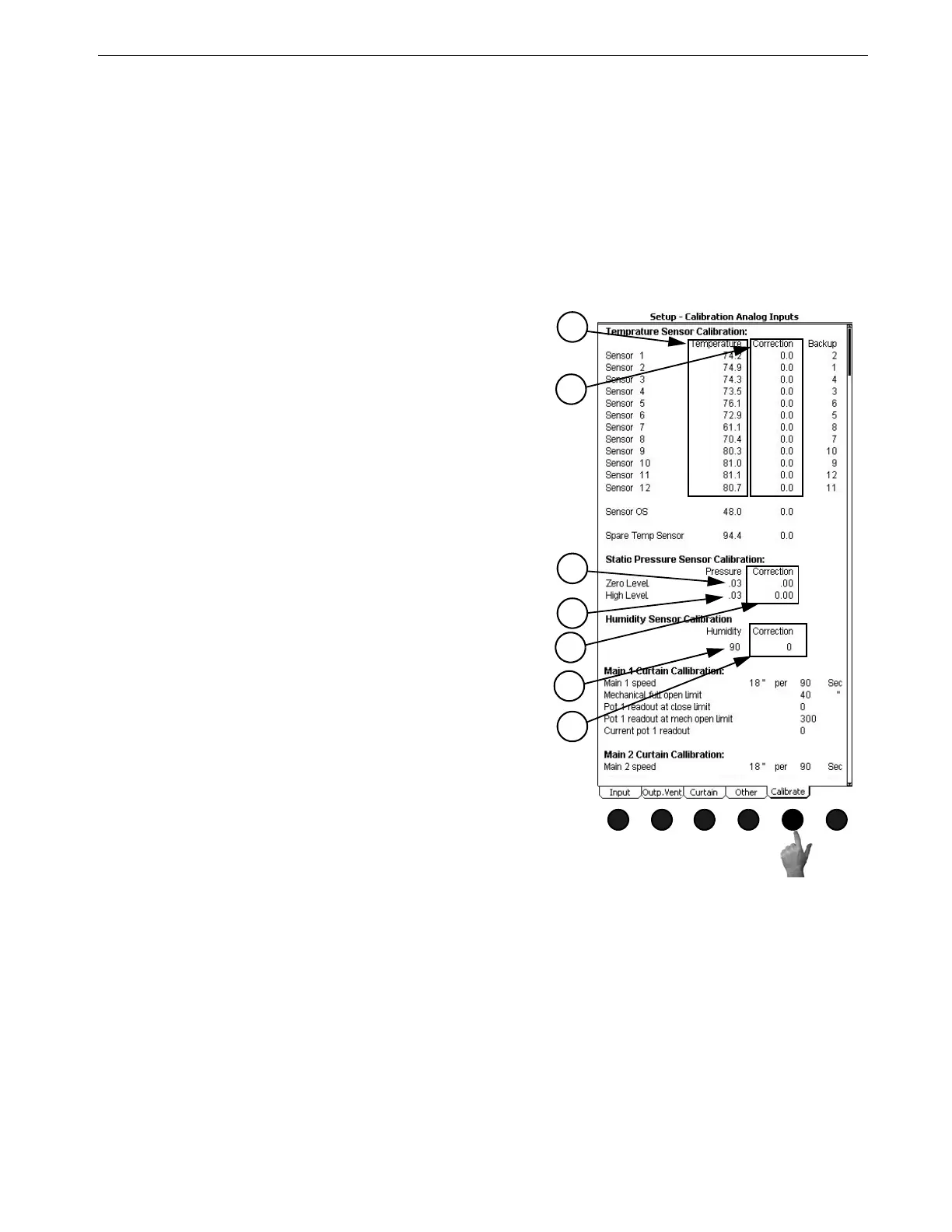

(Setup-Control Screen) Calibrate Analog Inputs Tab

To access the Setup-Control "Calibrate Analog Inputs Tab", press the Tab Key below "Calibrate". This

screen allows the user to assign backup temperature sensors and to re-calibrate Inputs if necessary. It is

strongly recommended that every sensor have a backup assigned to it. This backup sensor will take over

operation if the primary sensor fails. It is recommended that the backup sensor be in the same general area

as the primary sensor. As a default, every sensor is backed up by the next sensor below it. For example,

sensor 6 is backed up by sensor 5.

The re-calibration section of this screen should not need to be used at initial installation and start-up of

the Control unless natural ventilation is used. If natural ventilation is being used then the potentiometers

will need to be calibrated at this time. If it is felt that one of the Inputs needs to be re-calibrated perform

the following steps…

Relative Humidity Sensor

To re calibrate the Relative Humidity Sensor first obtain a sling psychrometer or other humidity-

measuring device. Operate the psychrometer in the same area that the Relative Humidity Sensor is

installed. Take the reading on the psychrometer and compare it to the reading on the Setup-Control

"Calibration" Screen (Figure 69, above). If the readings do not match, then change the reading under the

Humidity column, (Item 6), to match the reading of the psychrometer. The correction column, (Item 7),

is to be used for service information and for returning to factory settings only.

MT1842-083 10/04

1

Figure 69. Setup-Control Screen:

Calibrate Tab

Temperature Sensors

To re-calibrate the Temperature Sensors, first obtain a

digital thermometer that has a readout of at least .1°. Do not

use a temperature gun. A temperature gun takes object

temperatures, not air temperatures. Place the digital

thermometer next to the Temperature Sensor that is being

re-calibrated. Take the reading from the digital thermometer

and enter that number under the temperature column, (Item 1

Figure 69), of the Sensor being calibrated. The Correction

column, (Item 2), is used only for service information and to

return the Control to the factory settings. The settings should

be reset to factory whenever a re-calibrated Temperature

Sensor is replaced. To return to factory settings change the

number under the correction column by one digit.This will

cause the correction to automatically zero out and return to

factory setting.

Static Pressure Sensor

To re-calibrate the Static Pressure Sensor first obtain a

manometer or other static pressure measuring device. Then

disconnect both hoses from the Static Pressure Sensor.

Go to the static pressure portion of the screen and look

at the Pressure reading on the Zero Level line (Item 3).

If the reading is not zero then change the zero level

pressure to read zero. The zero level has now been calibrated.

To calibrate the high level, first make sure that the Manometer

has been installed in the house and reconnect the hoses to the

Static Pressure Sensor. Open the Inlets slightly and turn on

enough Fans to create a static pressure of at least 0.15 inches

of w.c. at the Manometer. Compare the Manometer reading to

the reading on the High Level line on the Control (Item 4). If

the readings do not match, edit the pressure reading on the

High Level line to match the reading of the Manometer. As

with the Temperature Sensors, the Correction column, (Item

5), of the static pressure calibration is used for service, and to

return the Control to factory settings only. This completes the

re-calibration of the static pressure Sensor.

1

2

3

4

5

6

7

Loading...

Loading...