74

PID Control

Proportional Integral and Derivative control maintains

accurate and stable levels in a process (e.g. tempera-

ture control). It avoids the oscillation characteristic of

On-Off control by continuously adjusting the output to

keep the process variable stable at the desired Set-

point.

Also refer to Automatic Reset, Controller, Manual

Mode, On-Off Control, PI Control, Heat Proportional

Band, Process Variable, Rate, Cool Proportional Band,

Setpoint and Tuning

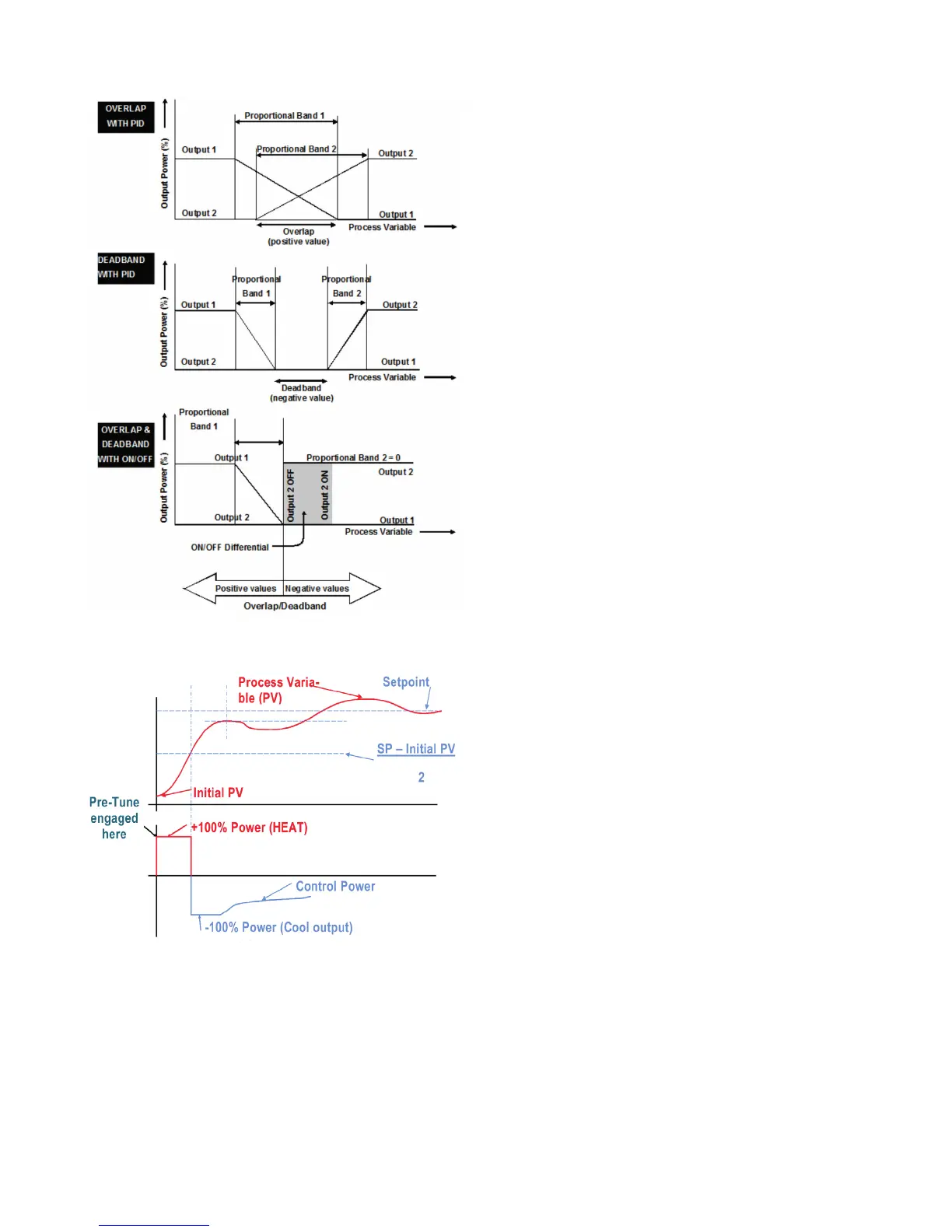

Pre-Tune

Starting with the load cool*, Pre-Tune disturbs the pro-

cess start-up pattern, so that the PID values are calcu-

lated before the setpoint is reached.

During Pre-Tune, the controller outputs full Heat Power

until the process value has moved approximately half-

way to the Setpoint. At that point, power is removed

(or full Cool Power with dual control), thereby introduc-

ing a process oscillation. Once the oscillation peak has

passed, the instrument calculates the PID tuning terms:

proportional band(s), automatic reset and rate. Normal

PID control operation begins using these calculated

values, and Pre-Tune automatically disengages.

*Ideally the Tune program should be used when the

load temperature is close to ambient.

Care should be taken to ensure that any overshoot is

safe for the process and if necessary tune at a lower

setpoint.

Pre-Tune will not engage if either Heat or Cool outputs

on a controller are set for On-Off control, the control-

ler is set to Manual, during Setpoint ramping, or if the

process variable is less than 5% of the input span from

the Setpoint. Refer to the Automatic Tuning section for

further details.

Also refer to Automatic Reset, On-Off Control, Input

Span, PID, Heat Proportional Band, Process Vari-

able, Rate, Cool Proportional Band, Setpoint, Setpoint

Ramping and Tuning.

PV High Alarm Value

Refer to Alarm Operation.

PV Low Alarm Value

Refer to Alarm Operation.

Loading...

Loading...