OPERATION WELDSKILL 200AC/DC INVERTER

Manual 0-5206 4-7 Operation

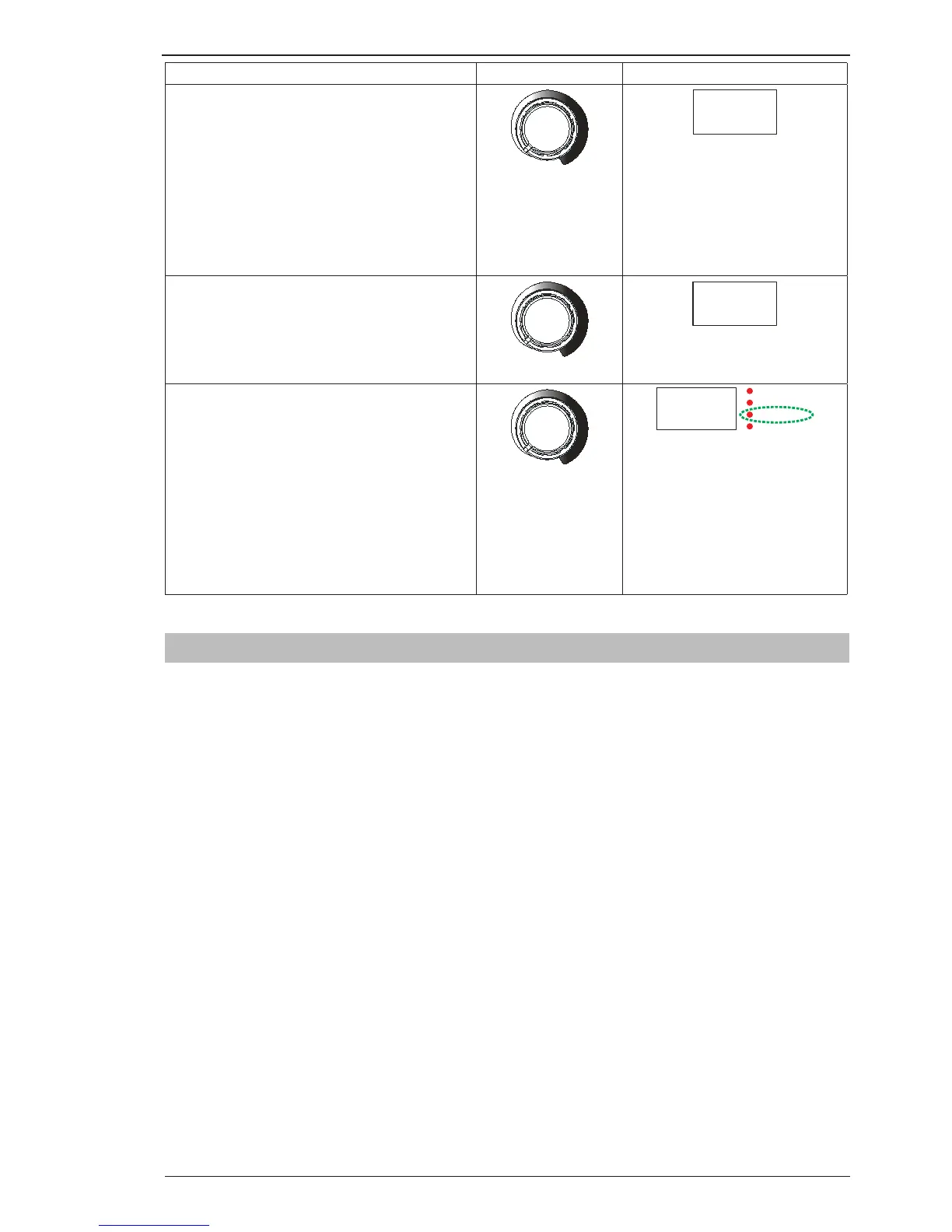

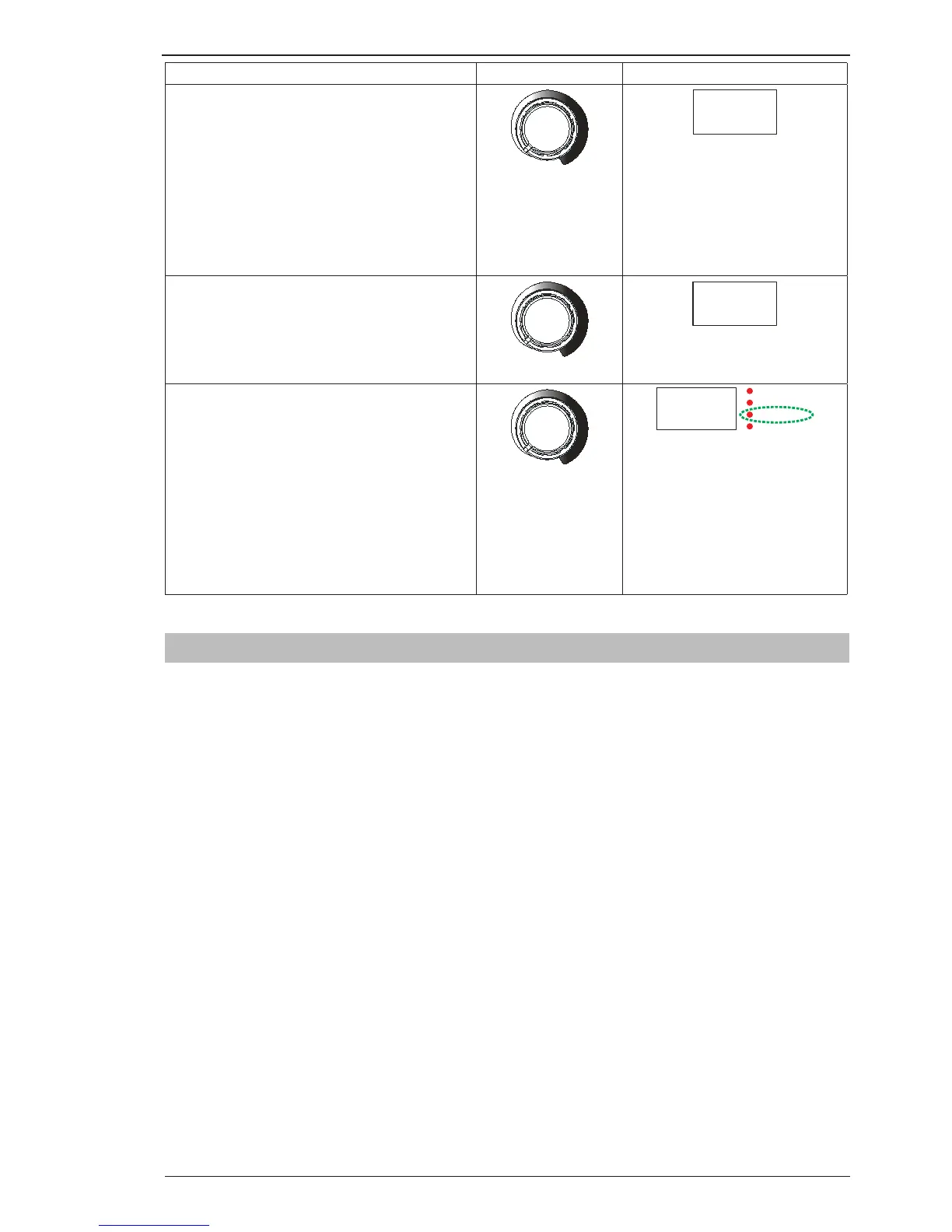

Programming Parameter Adjustment Device Display

Hot Start

This parameter operates in all weld modes

except LIFT TIG mode and is used to heat up

the weld zone in TIG modes or improve the

start characteristics for stick electrodes the

peak start current on top of the BASE (WELD)

current.

e.g. HOT START current = 130 amps when

BASE (WELD) = 100 amps & HOT START = 30

amps

0 to 70A (max 170A weld current)

Base Current

This parameter sets the TIG WELD current

when PULSE is OFF. This parameter also sets

the STICK weld current.

5 to 170A (DC STICK mode)

10 to 170A (AC STICK mode)

Arc Force (STICK Mode only)

Arc Force is effective when in Manual Arc

Mode only. Arc Force control provides and

adjustable amount of Arc Force (or "dig")

control. This feature can be particularly

beneficial in providing the operator the ability

to compensate for variability in joint fit-up in

certain situations with particular electrodes. In

general increasing the Arc Force control toward

100% (maximum Arc Force) allows greater

penetration control to be achieved.

Volts

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

0 to 100%

Table 4-2

4.03 WELDSKILL 200AC/DC – LIFT TIG and HF TIG Programming Mode

Press the PROCESS button to select LIFT TIG or HF TIG mode.

Press the MODE switch to goggle between AC and DC welding output.

The Programming LED's are always active. Press FORWARD or BACK to cycle through available programming

functions.

Use the Multi Function Control to adjust the parameter selected.

100

Loading...

Loading...