CHAPTER7

If

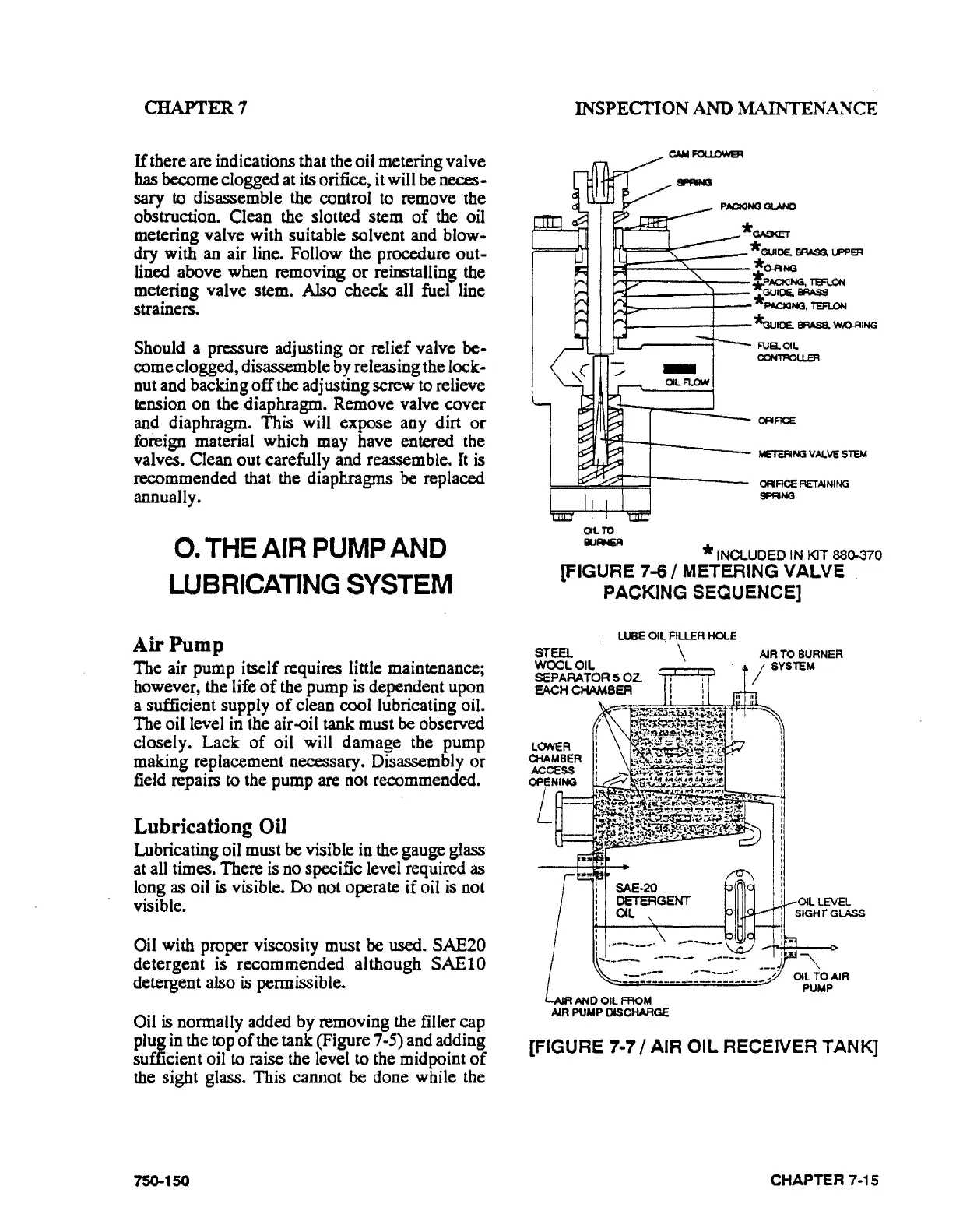

there are indications that the oil metering valve

has

become clogged at its orifice, it will be neces-

sary to disassemble the control to remove the

obstruction. Clean the slotted stem

of

the oil

metering valve with suitable solvent and blow-

dry with an air line. Follow the procedure

out·

lined above when removing

or

reinstalling the

metering valve stem.

Also check all fuel line

strainers.

Should a pressure adjusting

or

relief valve be-

come clogged, disassemble by releasing the lock-

nut and backing

off

the adjusting screw to relieve

tension on the diaphragm. Remove valve cover

and diaphragm. This will expose any dirt or

foreign material which may have entered the

valves. Clean out carefully and reassemble.

It

is

recommended that the diaphragms

be

replaced

annually.

0.

THE

AIR

PUMP

AND

LUBRICATING

SYSTEM

Air

Pump

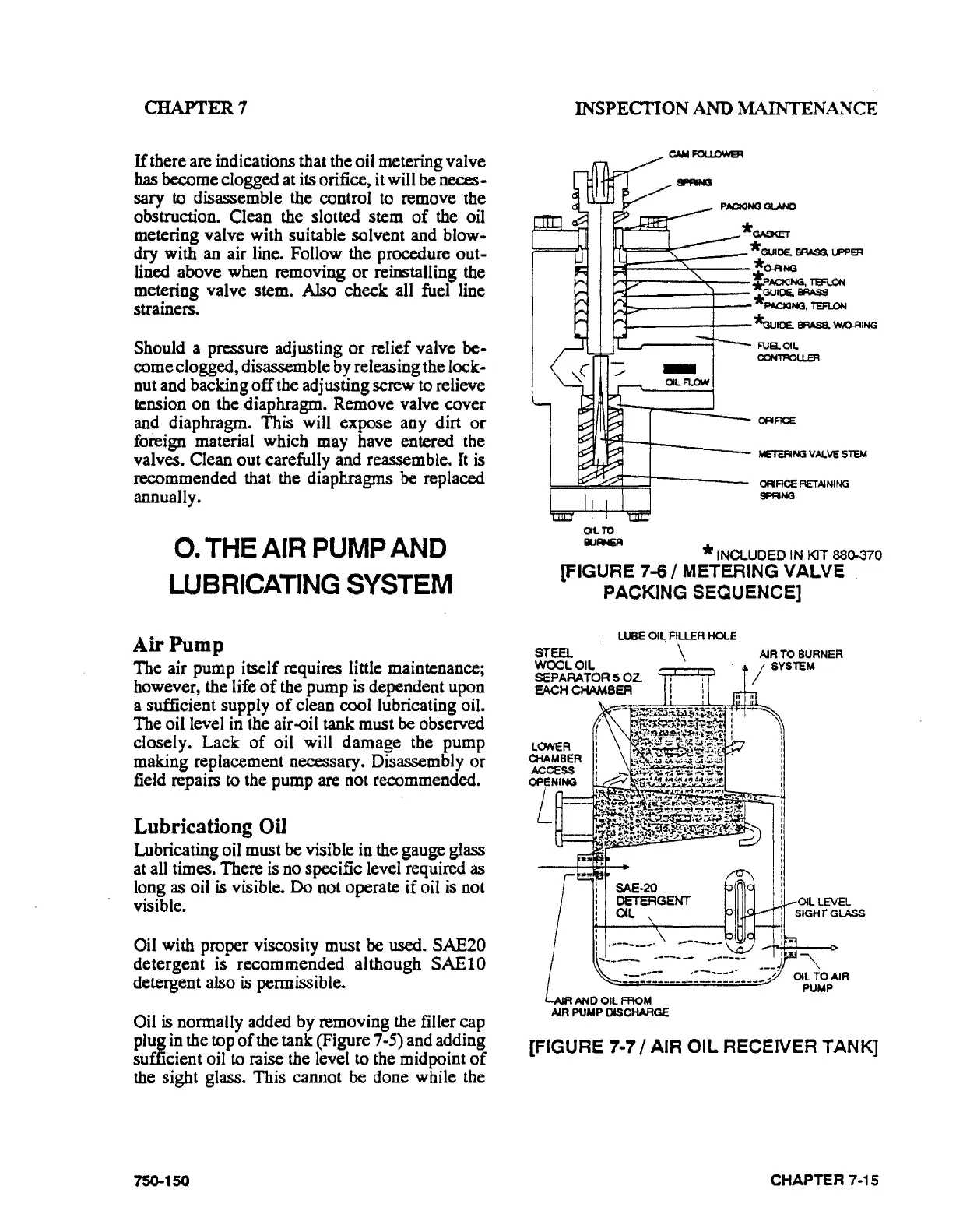

The air pump itself requires little maintenance;

however, the life

of

the pump is dependent upon

a

su:f:ficient

supply

of

clean cool lubricating oil.

The oil level in the air

..oil

tank must be observed

closely. Lack

of

oil will damage the pump

making replacement necessary. Disassembly or

field repairs

to the pump are not recommended.

Lubricationg Oil

Lubricating oil must

be

visible in the gauge glass

at all times. There is no specific level required

as

long as oil

is

visible. Do not operate

if

oil

is

not

visible.

Oil

with proper viscosity must

be

used. SAE20

detergent is recommended although SAElO

detergent also

is

permissible.

Oil

is

normally added by removing the filler cap

plug in the top

of

the tank (Figure 7-5) and adding

sufficient oil

to raise the level to the midpoint

of

the sight glass. This cannot be done while the

750-150

INSPECI'ION

AND MAINTENANCE

P.a<ING

GLANO

*GASKET

*GUICE.

BRASS, UPPER

~===s:;::==

*0-ANG

1.-T':.?"'""--~--

~ACKING,

TEFLON

~-----t--

*GUICE, BRASS

PACKING,

TEFl.ON

l-----+--*wiOE.

E1F'AS8,

W~ING

FUS.OIL

CCINTFW:)IJ.ER

OFIIACE

METERING

VALVE

STEM

CRACE

RETAINING

SPRNG

OIL

TO

EIJFIER

*

INCLUDED

IN

KIT

88~370

[FIGURE

7-6/

METERING VALVE

PACKING SEQUENCE]

LUBE

OIL FILLER

HOlE

srea..

WOOL

OIL

SEPARATOR

5

OZ.

EACH

CHAMBER

I

I

. \

AIR

TO

BURNER

I

SYSTEM

OIL

LEVEL

SIGHT GLASS

l

...

~---

-------

.------

),

,.

"""""

~:::.::::

____

~:::::::~----./

OIL

TO

AIR

AIR

AHO

OIL

FROM

AIR

PUMP

DISCHARGE

PUMP

[FIGURE 7·7 I AIR OIL RECEIVER TANK]

CHAPTER 7-15

Loading...

Loading...