CHAPTERS

To obtain the required number

of

cubic feet per

hour

of

gas,

divide

the

heating

value

(BTU/CU.Ff.) into the required burner input

(BT.U/HR. ).

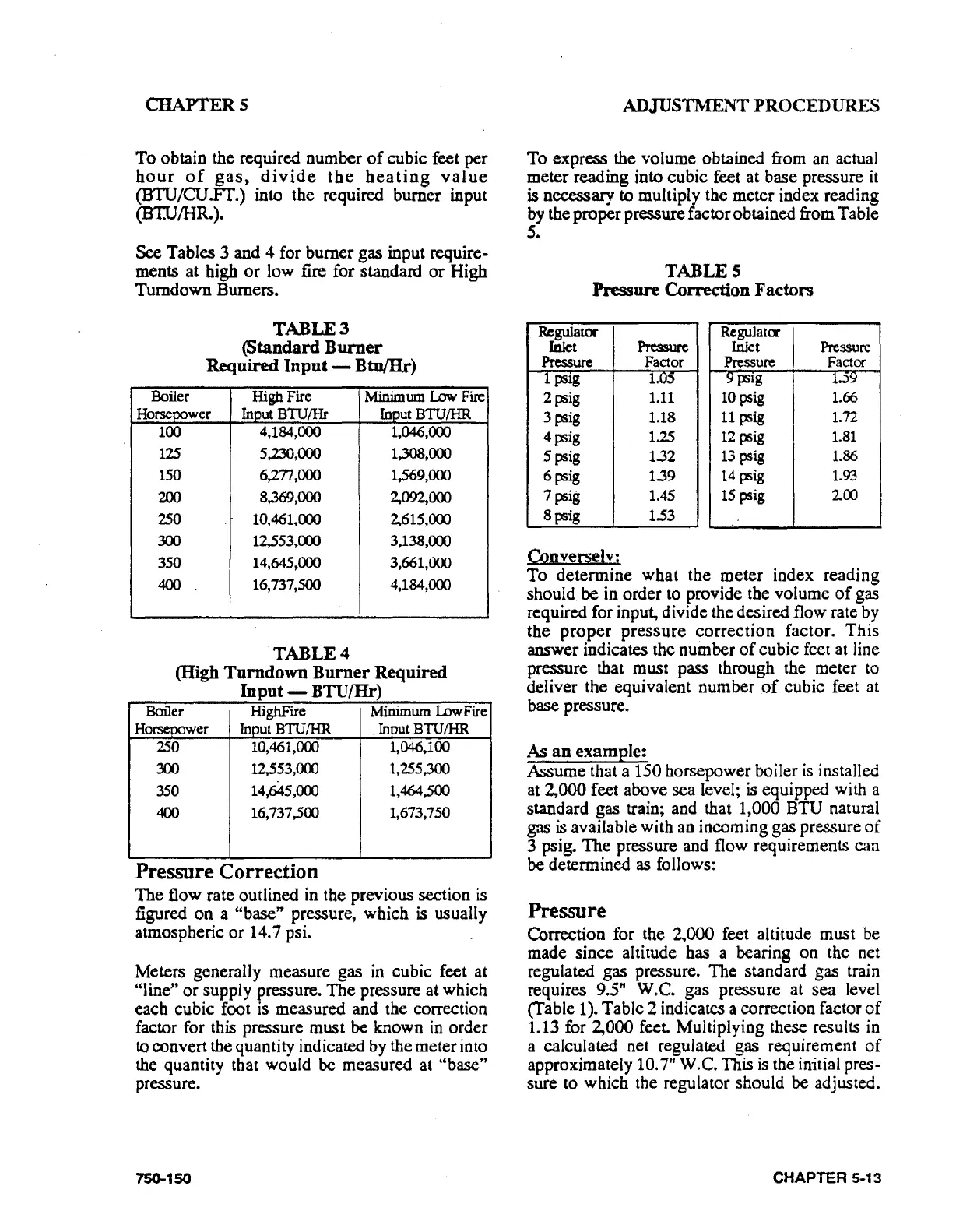

See Tables 3 and 4 for burner gas input require-

ments at high

or

low fire for standard

or

High

Turndown Burners

..

Boiler

TABLE3

(Standard

Burner

Required

Input-

Btu/H.r)

Higb Fire Minimum

Low

Fire

Horsepower

Input BTU/Hr Input

BTU!HR

100

4,184,()(X)

1,046,()(X)

125

5,230,000

1,308,000

150

6;2.77

,()(X)

1,S69,()(X)

200

8,369,000

2,~()(X)

250

10,461,(X)()

2,615,()(X)

3(X)

12,553,(X)()

3,138,000

350

14,645,<XX>

3,661,()(X)

400 16,737,500

4,184,()(X)

TABLE4

(High

Turndown

Burner

Required

Input-

BTU/Hr)

Boiler HighFire Minimum LowFire

Horsepower

Input

BTUIHR

.

Input

BTUIHR

250

10,461,000 1,046,100

300

12,553,000 1,255,300

350

14,645,000 1,464,500

400

16,737,500

1,673,750

Pressure Correction

The flow rate outlined in the previous section

is

figured on a "base" pressure, which

is

usually

atmospheric

or

14.7 psi.

Meters generally measure gas

in

cubic feet at

"line"

or

supply pressure. The pressure at which

each cubic foot

is

measured and the correction

factor for this pressure must be known

in

order

to convert the quantity indicated by the meter into

the quantity that would

be measured at "base"

pressure.

750-150

ADJUS~PROCEDURES

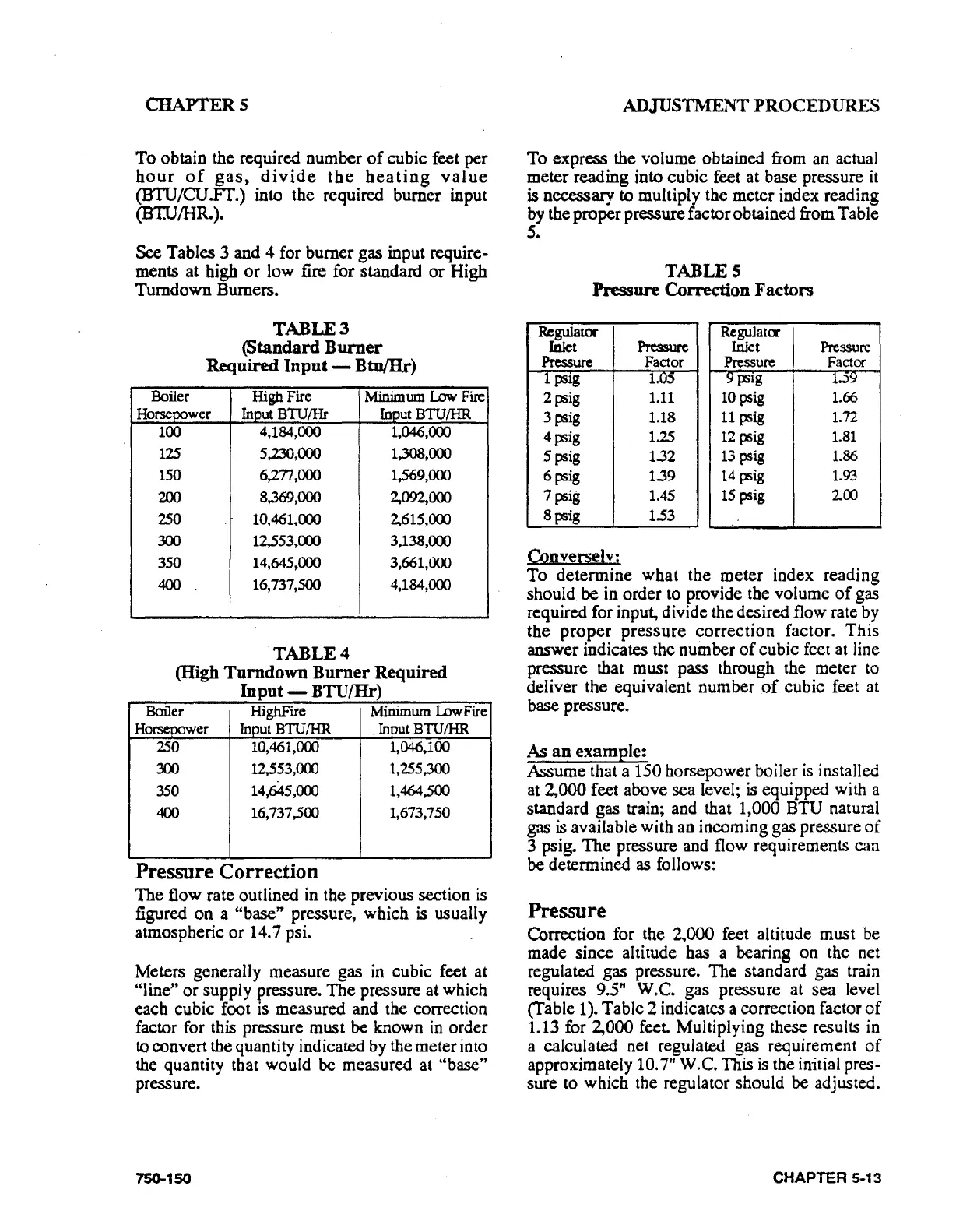

To express the volume obtained from an actual

meter reading into cubic feet at base pressure

it

is

necessary to multiply the meter index reading

by

the proper pressure factor obtained from Table

s.

TABLES

Pressure Correction Factors

Regulator

Inlet

Pressure

Regulatcr

lnJet

Pressure

Pressure

Factor Pressure Factor

1

pstg

1.05

~

pstg

1 •

.:>9

2psig

1.11

10

psig

1.66

3 psig 1.18

11

psig 1.72

4psig 1.25

12

psig

1.81

5 psig 1.32

13

psig

1.86

6psig 1.39

14

psig 1.93

7psig 1.45

15

psig

2.00

8psig

1.53

Conversely;

To determine what the meter index reading

should. be in order to provide the volume

of

gas

required for input, divide the desired flow rate by

the

proper

pressure

correction

factor. This

answer indicates the number

of

cubic feet at line

pressure that must pass through the meter

to

deliver the equivalent number

of

cubic feet at

base pressure.

As

an

example:

Assume that a 150 horsepower boiler

is

installed

at

~000

feet above sea level;

is

equipped with a

standard gas train; and that

1,000 BTU natural

gas

is

available with an incoming gas pressure

of

3 psig. The pressure and flow requirements can

be determined as follows:

Pressure

Correction for the 2,000 feet altitude must

be

made since altitude has a bearing on the net

regulated gas pressure. The standard gas train

requires

9.5"

W.C. gas pressure at sea level

(Table 1). Table 2 indicates a correction factor

of

1.13 for 2,000 feet Multiplying these results

in

a calculated net regulated gas requirement

of

approximately 10.

7"

W.C. This

is

the initial pres-

sure to which the regulator should be adjusted.

CHAPTER 5-13

Loading...

Loading...