CHAPTERS

ADJUSTMENT PROCEDURES

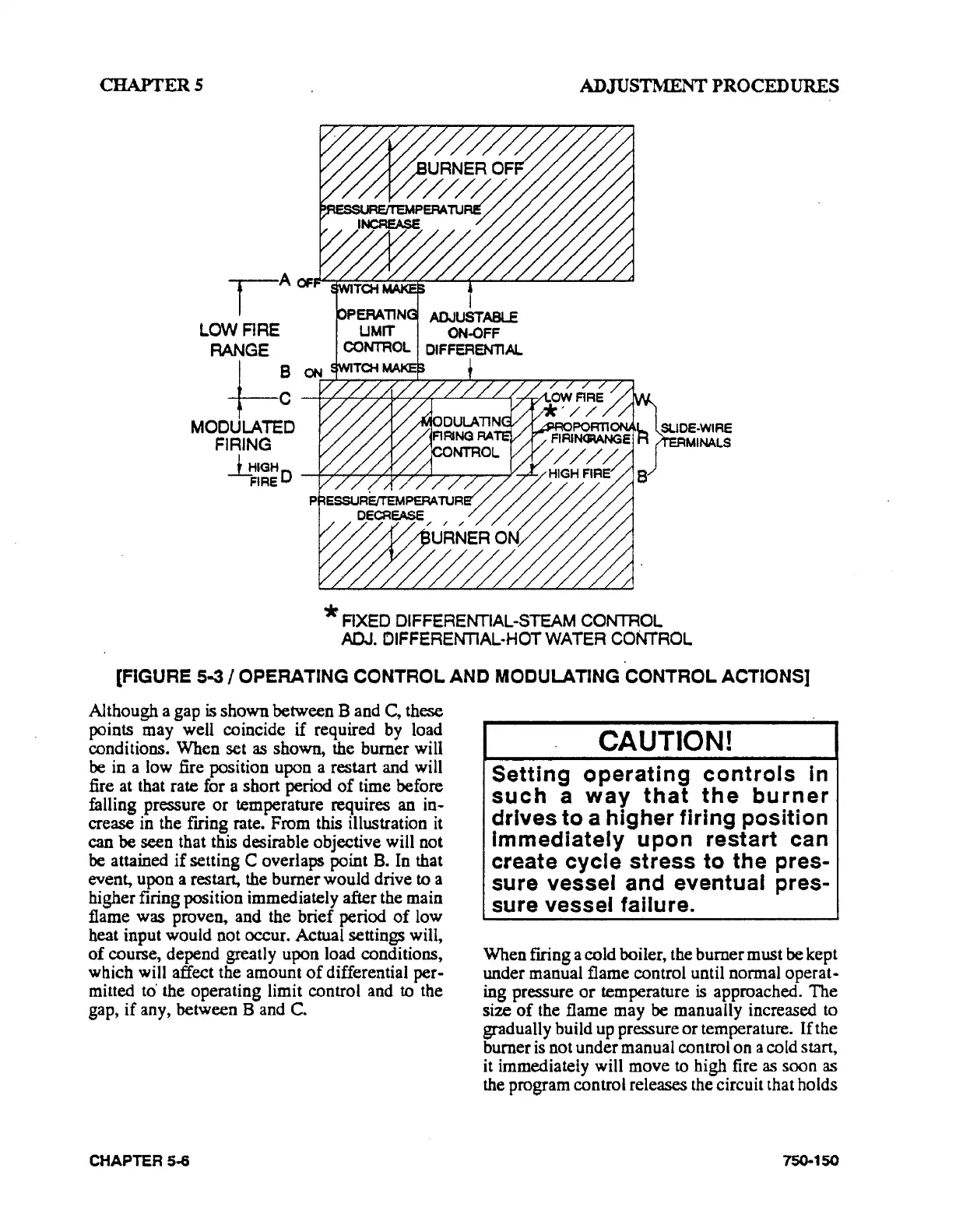

*FIXED

DIFFERENTlAL-STEAM CONTROL

ADJ.

CIFFEREM1AL-HOTWATER CONTROL

[FIGURE

5-3/

OPERATING CONTROL AND MODULATING CONTROL ACTIONS]

Although a gap

is

shown between B and C, these

points may well coincide

if

required by load

conditions. When set

as shown, the burner will

be

in a low fire position upon a restart and will

fire at that rate for a short period

of

time before

falling

pressure

or

temperature requires an in-

crease in the fuing rate. From this illustration

it

can be seen that this desirable objective will not

be

attained

if

setting C overlaps point

B.

In that

event, upon a restart, the burner would drive

to a

higher firing position immediately after the main

flame was proven, and the brief period

of

low

heat input would not occur. Actual settings will,

of

course, depend greatly upon load conditions,

which will affect the amount

of

differential per-

mitted

to·

the operating limit control and to the

gap,

if

any, between B and C.

CHAPTER 5-6

CAUTION!

Setting

operating

controls

in

such

a

way

that

the

burner

drives

to

a

higher

firing

position

Immediately

upon

restart

can

create

cycle

stress

to

the

pres-

sure

vessel

and

eventual

pres-

sure vessel failure.

When fuing a cold boiler, the burner must

be

kept

under manual flame control until normal operat

..

ing pressure

or

temperature

is

approached. The

size

of

the flame may

be

manually increased to

gradually build up pressure

or

temperature.

If

the

burner

is

not under manual control on a cold start,

it

immediately will move to high fire as soon as

the program control releases the circuit that holds

750-150

Loading...

Loading...