CHAPTERS

D.

MODULATING

MOTOR

SWITCHES

-

LOW

FIRE

AND

HIGH

FIRE

The modulating motor contains either one

or

two

internal switches depending upon application.

These

single-pole,

double-throw,

micro-

switches are actuated by adjustable cams

at·

tached to the motor shaft.

Factory replacement motors have the cams

preset. The low fire start switch

1s

set to make the

red and yellow leads at approximately

s·

on the

motor closing. The high tire purge air proving

switch (M954B motor)

is

set to make red and

blue tracer leads at approximately

60. on motor

opening. Normally these settings are left as

is

but

job

conditions may require readjustment.

If

the cams require adjustment

or

resetting, fol-

low the instructions in the manufacturer's Tech-

nical Manual.

E.

BURNER

OPERATING

CONTROLS

-

GENERAL

In general, when adjusting controls check

to

see

that they are level, especially those containing

mercury switches.

On temperature sensing con-

trols, make sure that the bulb

is

properly bot-

tomed in its well and that connecting tubing

is

not kinked.

Controls are carefully calibrated during their

manufacture

and

normally

do

not

require

recalibration. The dial settings generally are

quite accurate although it

is

not

unus~al

to have

a slight variation between a scale

setting and an

actual pressure gauge

or

the~ometer

readi~g

and to readjust the control settmg to agree wtth

these readings. This

is

predicated, however, on

pressure· gauges and thermometers being ac-

curate.

75()...150

ADJUSTMENT

PROCEDURES

Burner controls properly set to match load

demands will provide operational advantages

and achieve the following desirable objectives:

(a)

The

burner will operate in low fire

position prior

to shut down.

(b)

The

burner will operate at low fire for

a brief period on each start during normal

operation.

(c) Frequent bumeron-offcycling will be

avoided.

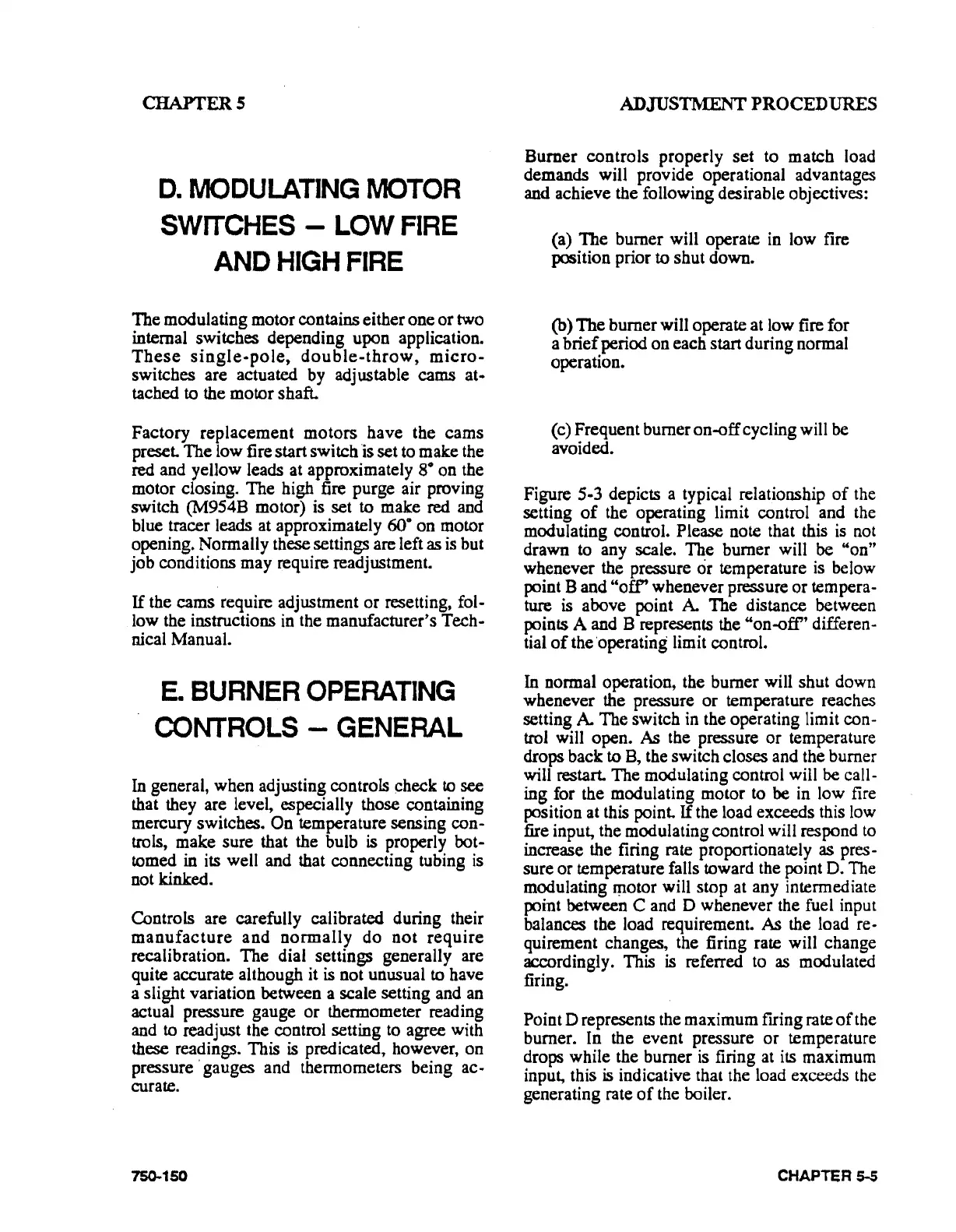

Figure 5

..

3 depicts a typical relationship

of

the

setting

of

the operating limit control

.an~

the

modulating control.

Please note that

thlS

IS not

drawn to any scale. The burner will be

"on"

whenever the pressure

or

temperature

is

below

point B and

"off'

whenever pressure

or

tempera-

ture

is

above point A The distance between

points

A and B represents the "on-off'' differen-

tial

of

the ·operating limit control.

In normal operation, the burner will shut down

whenever the pressure

or

temperature reaches

setting A. The switch in the operating limit

con-

trol will open. As the pressure

or

temperature

drops back

to B, the switch closes and the burner

will restart. The modulating control will

be

call-

ing for the modulating motor to be in

lo~

fire

position at this point.

If

the load exceeds this low

fire input, the modulating control will respond

to

increase the firing rate proportionately as pres-

sure

or

temperature falls toward the point D. The

modulating motor will stop at any intermediate

point between C and D whenever the fuel input

balances the load requirement.

As the load re-

quirement changes, the firing rate will change

accordingly. This

is

referred to as modulated

firing.

Point D represents the maximum firing rate

of

the

burner. In the event pressure

or

temperature

drops while the burner

is

firing at

its

maximum

input, this

is

indicative that the load exceeds the

generating rate

of

the boiler.

CHAPTER 5-S

Loading...

Loading...