CHAPTER 2

THE

PRESSURE VESSEL

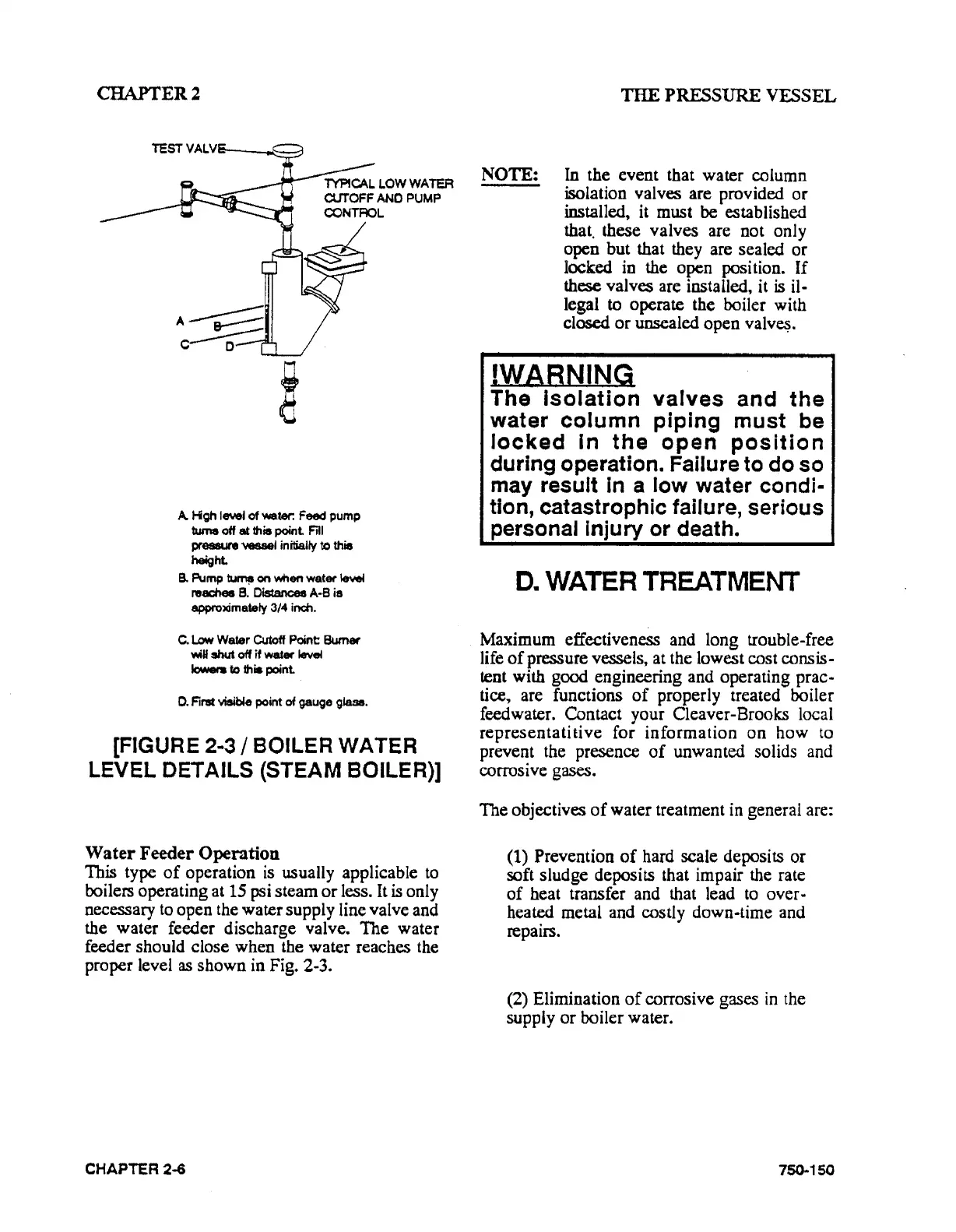

A

Hgh

level

of

water: Feed

pump

turns off at this point

Fill

pressure

"V88881

initially to thie

height

B.

Pump

tu~

on wnen water level

reac:tlee

B.

Dis:tances

A-8

is

approximately 3/4 inch.

C.

low

Water

Cutoff Point Burner

wiH

shut

off

if

water level

Jowers

to

thMa

point

0.

First

visi~e

point of gauge glase.

[FIGURE 2·3 I BOILER WATER

LEVEL

DETAILS (STEAM BOILER)]

Water

Feeder Operation

This type

of

operation

is

usually applicable to

boilers operating at

15

psi

steam

or

less.

It

is

only

necessary to open the water supply line valve and

the water feeder discharge valve. The water

feeder should close when the water reaches the

proper level

as

shown in Fig. 2-3.

CHAPTER

2..6

NOTE:

In the event that water column

isolation valves are provided

or

installed, it must

be

established

that. these valves are not only

open but that they are sealed

or

locked in the open position.

If

these valves are installed, it

is

il-

legal to operate the boiler with

closed

or

unsealed open

valv~.

!WARNING

The

Isolation

valves

and

the

water

column

piping

must

be

locked

In

the

open

position

during operation. Failure to do so

may

result in a low water condi-

tion, catastrophic

failure, serious

personal

injury

or

death.

D.

WATER

TREATMENT

Maximum effectiveness and long trouble-free

life

of

pressure vessels, at the lowest cost consis-

tent with good engineering and operating prac-

tice, are functions

of

properly treated boiler

feedwater. Contact your Cleaver-Brooks local

representatitive

for information

on

how to

prevent the presence

of

unwanted solids and

corrosive gases.

The objectives

of

water treatment

in

general are:

(1)

Prevention

of

hard scale deposits or

soft sludge deposits that impair the rate

of

heat transfer and that lead to over-

heated metal and costly down-time and

repairs.

(2) Elimination

of

corrosive gases

in

the

supply or boiler water.

750-150

Loading...

Loading...