CHAPTERS

Because

of

variation in oils including chemical

content, source, blends and viscosity charac-

teristics, the temperatures and pressures listed in

Chapter 4 and mentioned

in

the adjusting

of

the

controls in the following paragraphs will vary

and thus may

be regarded

as

tentative and may

need to

be

changed to provide best firing condi •

tions. Figure 5-7

is

an

oil viscosity-temperature

chart. This may

be

used

as

a guide, although your

oil supplier will

be able to give you more exact-

ing information based on

an

analysis

of

the oil.

Review

of

the applicable maintenance instruc-

tions given in Chapter 7 will aid

in

maintaining

an efficient fuel system.

NOTE:

To prevent oil heater coking, the

fuel oil pump must

be

in

opera-

tion during all times that an oil

heater

is

in service. During any

time that the oil pump is not

operating, the oil heating system

must

be electrically shut down

by

manually turning the oil heater

switch to the

"off'

position.

When the boiler

is

shut down, or switched over

to

gas firing, the pump must operate for a suffi-

cient period

of

time

to

cool the oil heater.

Similarly, if

an

electric, steam, or hot water oil

heater

is

removed for servicing, the temperature

of

the heater should

be

reduced by circulating oil

until it has cooled.

·

U.

FUEL OIL

COMBUSTION

ADJUSTMENT

After operating for a sufficient period

of

time

to

assure a warm boiler, adjustments should be

made to obtain efficient combustion.

Efficient combustion cannot solely

be judged

by

flame condition or color, although they may

be

used in making approximate settings. This

should

be

done so that there

is

a bright sharp

flame with no visible haze.

750-150

ADJUSTMENT

PROCEDURES

Proper setting

of

the air/fuel ratios at all firing

rates must

be established by the use

of

a com bus.

tion gas analyzer. This instrument measures the

flue gas content,

by

percentage,

of

either carbon

dioxide

(C02),

or

oxygen (02), and in some

cases,

smoke.

Burner efficiency

is

determined by the amount,

by

percentage,

of

C02

or

02

present

in

the flue

gas.

The

ideal

setting

from an

efficiency

standpoint

is

reached when the percentage

of

oxygen in the flue gas

is

zero.

It

is,

however,

more practical

to set the burner to operate with a

reasonable amount

of

excess air to compensate

for minor variations

in

the pressure, temperature,

or burning properties

of

the oil. Fifteen to twenty

percent excess air

is

considered reasonable and

this should result

in

an

approximate

C02

value

of

12.5-13% for

No.2

oil and 13.5-14% for No.

6 oil with an

02

value

of

3.5-3%.

OIL

METERING

VALVE

DECREASE

FlOW

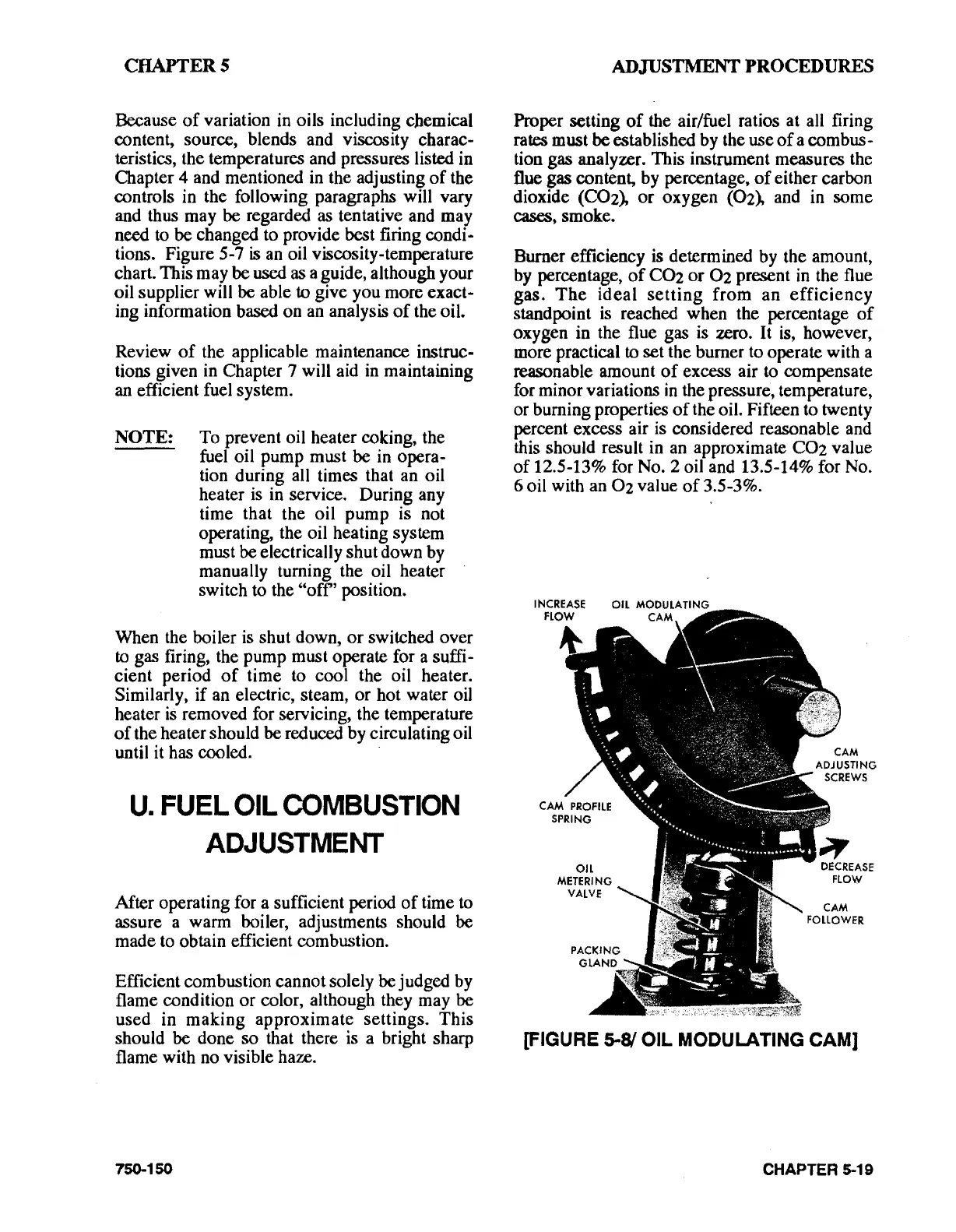

[FIGURE

5-81

OIL MODULATING CAM]

CHAPTER 5-19

Loading...

Loading...